- +48 573-568-355

- [email protected]

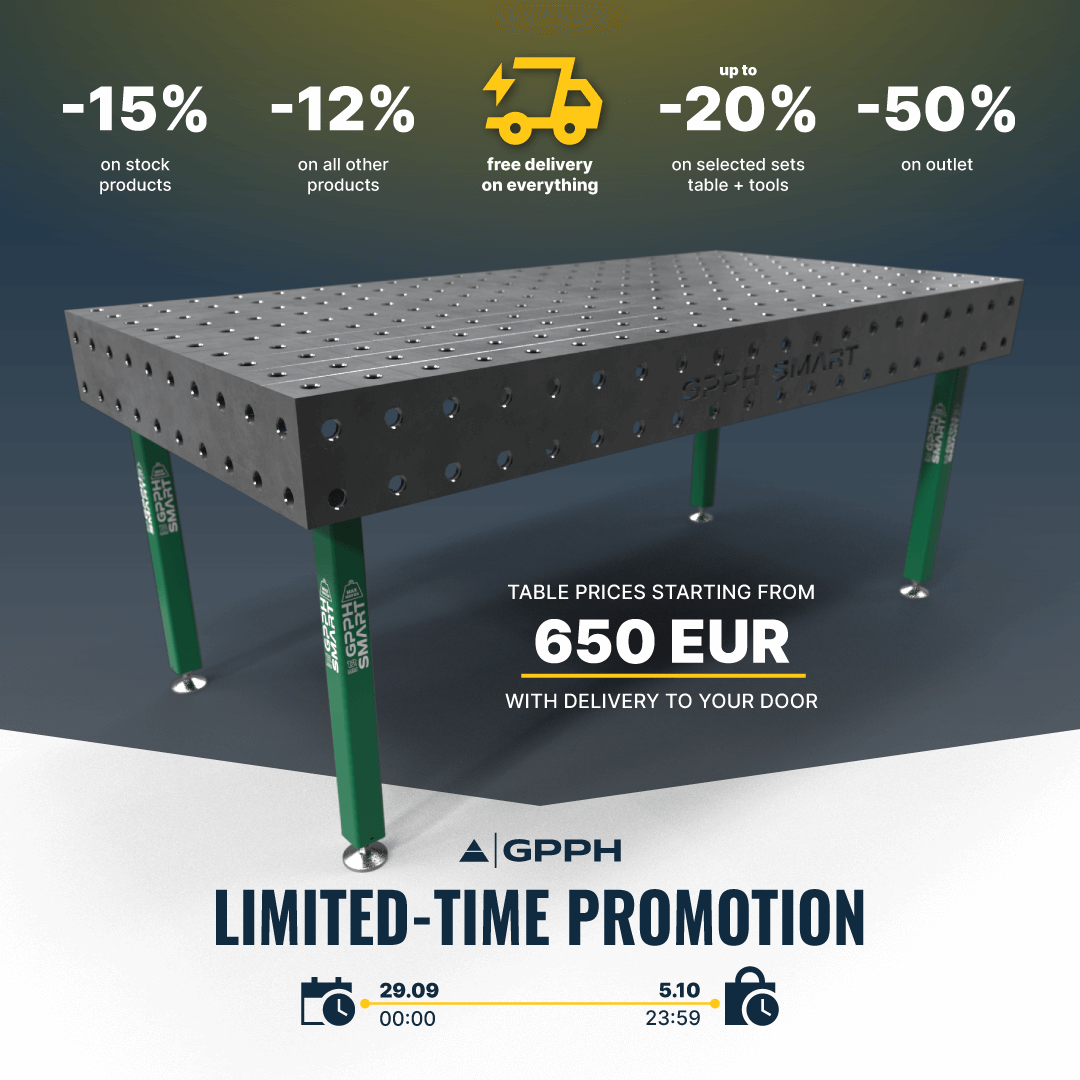

Free delivery to continental European countries

We have introduced regular weekly promotions. Some of their terms and conditions may change in the following week or may be maintained for another week.

PROMOTION STILL ON FOR