Welding tables can be used wherever precision is required during welding. You can use them for manual or robotic welding. Your structures will finally be made accurately, without unnecessary corrections!

It also ensures ergonomic and fast work while maintaining precision and repeatability of the structures.

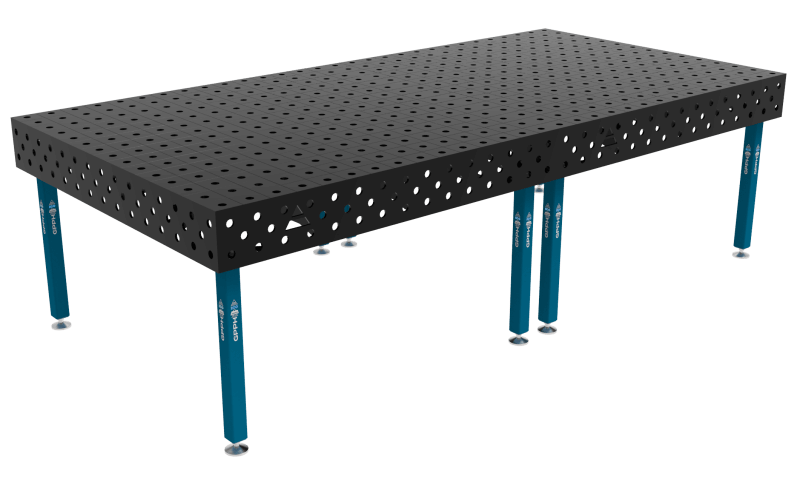

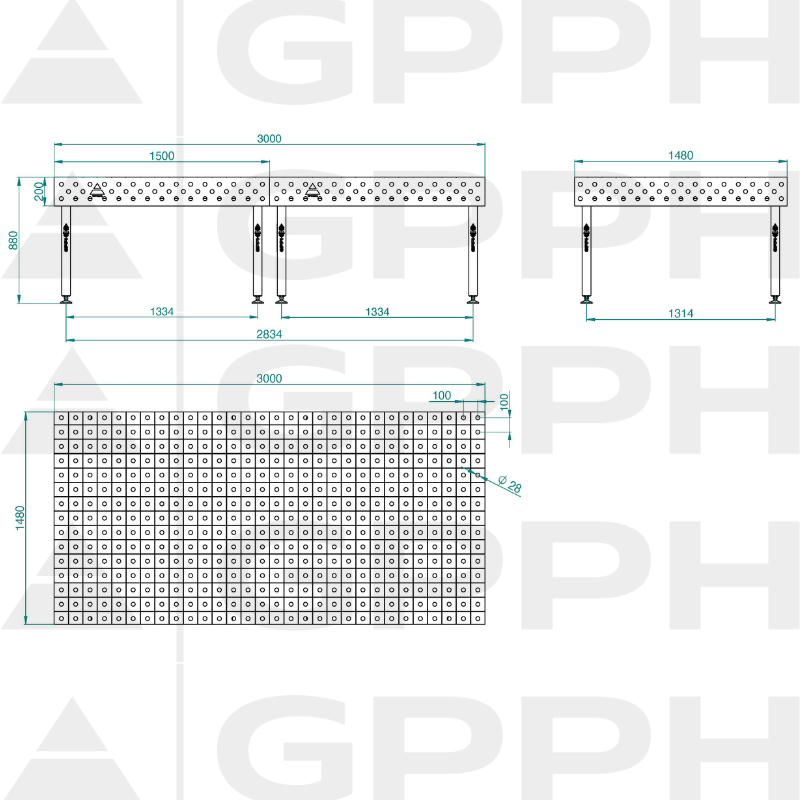

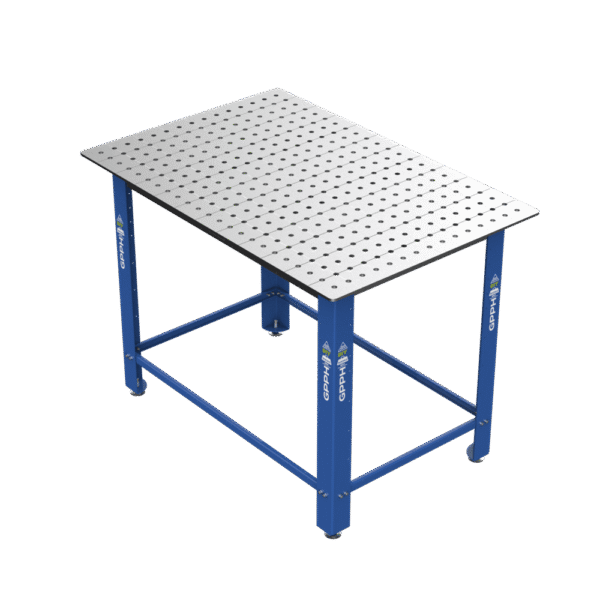

A welding table must be flat! The 8 mm thick ECO table tops have dense ribbing, which ensures a perfectly flat working surface. The table with dimensions of 3000×1480 mm has 3 longitudinal ribs and 6 longitudinal ribs. The solid and rigid base of the tabletop guarantees maximum stability during use and protection against deformation. The flatness tolerance of the table across the entire tabletop is ±0.5 mm*, and the tolerance of the holes in the welding table is ±0.1 mm. The GPPH welding table with dimensions of 3000×1480 consists of two interconnected welding tables with dimensions of 1500×1480.

It's up to you!

The engraved scale on the table top consists of vertical and horizontal lines in a 100x100mm grid. It serves as a reference point when setting up the structure and mounting tools. Using measuring tools, you can position your structure correctly to achieve the required dimensions.

The legs of ECO Welding Tables, made of 60×60 mm profile, have a load capacity of 250 kg/leg. For the 3000×1480 mm size, which has 8 legs, you get a maximum load capacity of 2,000 kg.

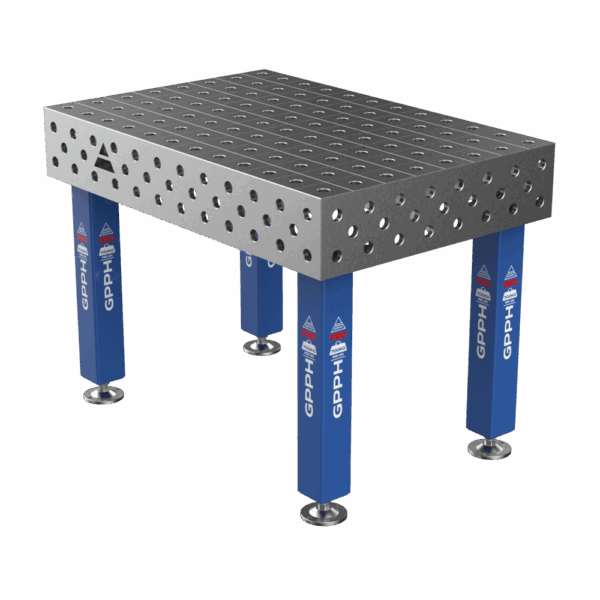

You have a choice: leg with foot or on wheels – check which one is better for you!

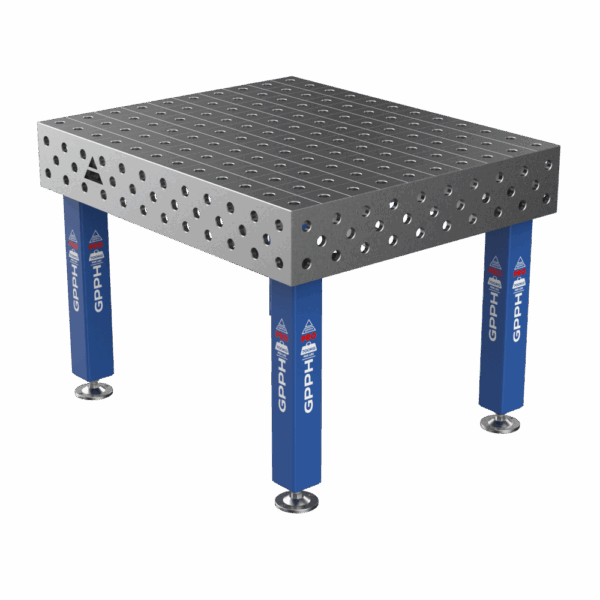

For work on ECO series welding tables, you can use PLUS milled tools, mounted with a 19-22 adjustable mounting pin. With them, you can precisely make any flat 2D and spatial 3D structure. And all this in much less time!

* provided that the table is correctly levelled