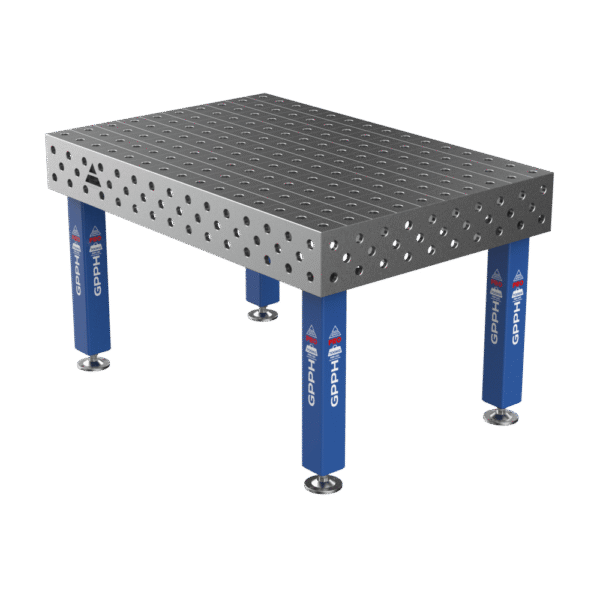

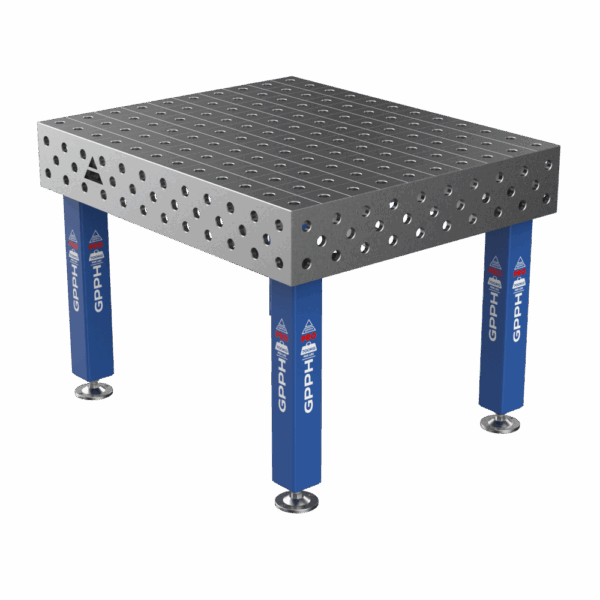

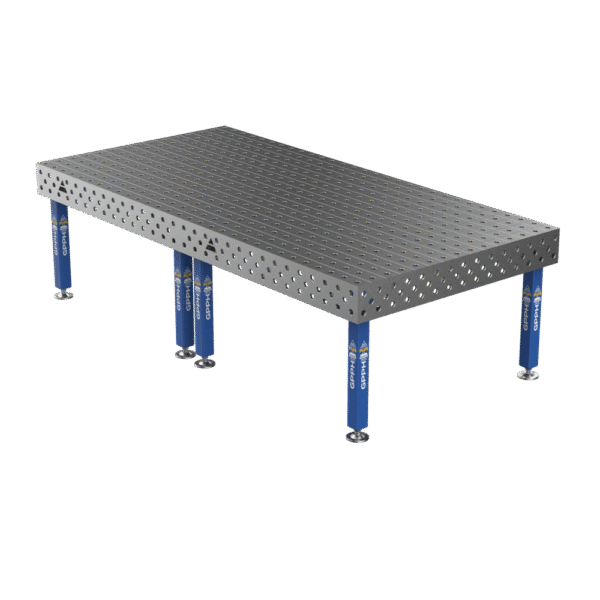

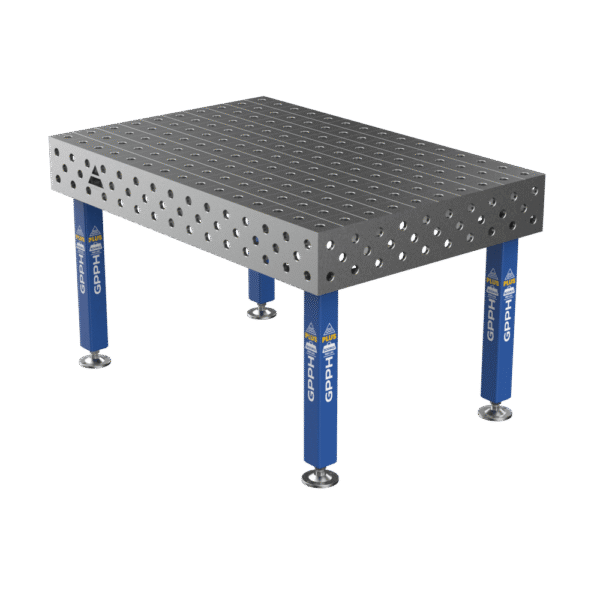

Welding tables can be used wherever precision is required during welding. You can use them for manual or robotic welding. Your structures will finally be made accurately, without unnecessary corrections!

It also ensures ergonomic and fast work while maintaining precision and repeatability of the structures.

A Welding Table Must Be Flat! The PLUS table tops, with a thickness of 12 mm, feature dense ribbing that ensures a perfectly flat working surface.

The table’s massive and rigid substructure guarantees maximum stability during use and protects the surface from deformation.

The flatness tolerance across the entire surface is ±0.3 mm*.

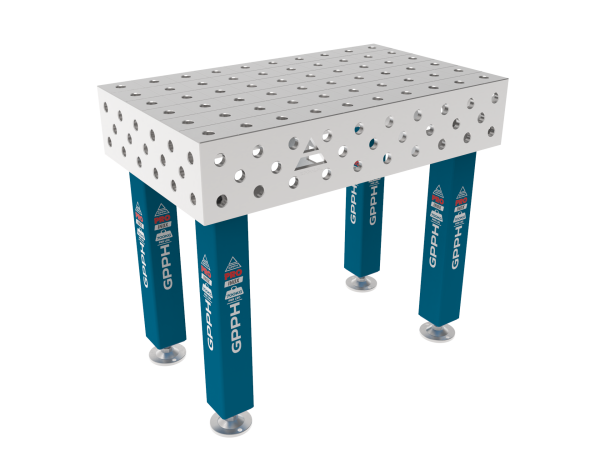

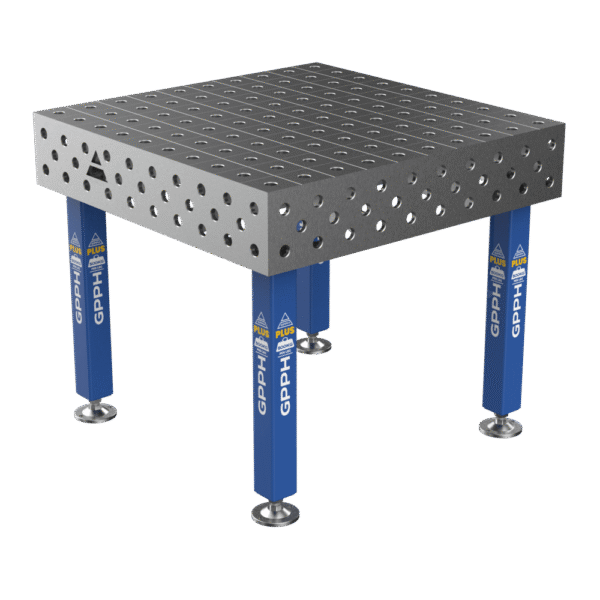

Stainless Steel Welding Tables from the INOX series are made of stainless steel grade 1.4301, which offers better electrical conductivity than standard steel – electrical resistivity at 20°C = 0.73 (Ω mm²)/m.

These tables are ideal for use wherever precise stainless steel welding is required.

Stainless steel welding tables are known for their high-quality craftsmanship and wear resistance. They are made from stainless steel with a high chromium content, which ensures durability and corrosion resistance.

Thanks to GPPH INOX Welding Tables, you can weld stainless steel structures without the risk of iron contamination or the formation of corrosion spots.

It's up to you!

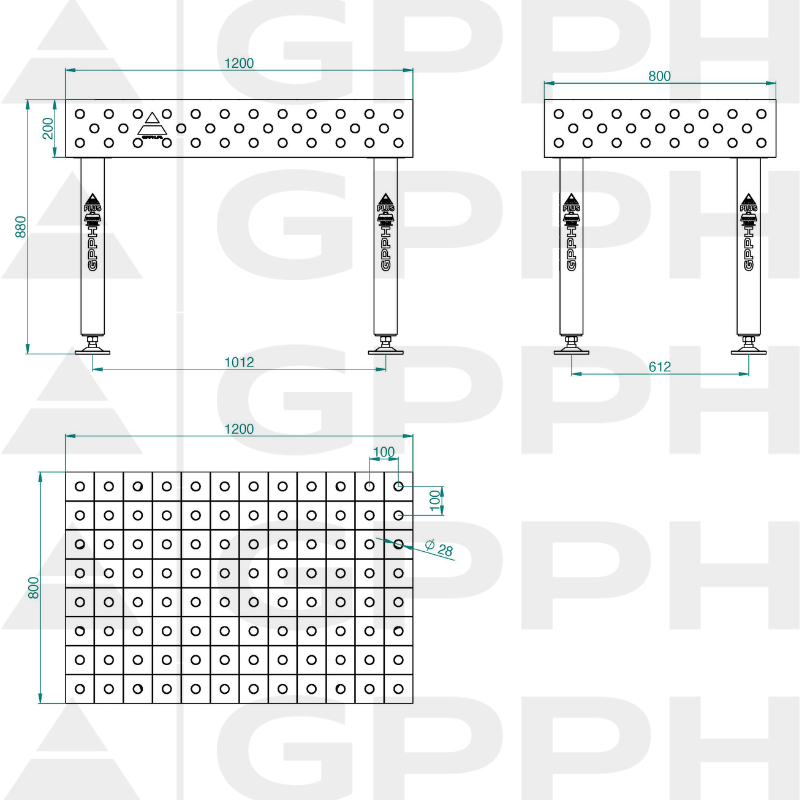

Milled and chamfered holes in the table top facilitate easy assembly and disassembly of tools during your work, thanks to the holes being precisely matched to the tools. This also contributes to less wear and tear on the tools – you do not need to use a lot of force to assemble and disassemble them. This design is the best solution available on the market for welding tables! The tolerance of the welding table holes is ±0.05 mm.

The engraved scale on the table top consists of vertical and horizontal lines in a 100x100mm grid. It serves as a reference point when setting up the structure and mounting tools. Using measuring tools, you can position your structure correctly to achieve the required dimensions.

The legs of PLUS INOX welding tables, made of 80×80 mm profile, have a load capacity of 500 kg/leg. For the 3000×1480 mm size, which has 8 legs, you get a maximum load capacity of 4,000 kg.

You have a choice: leg with foot or on wheels – check which one is better for you!

For work on PLUS INOX series welding tables, use PLUS milled tools. They will allow you to precisely make any flat 2D and spatial 3D structure. And all this in much less time!

*provided that the table is leveled correctly.