- +48 573-568-355

- [email protected]

The promotion is valid in selected countries of continental Europe.

PROMOTION STILL ON FOR

From 24 590,00 zł30 245,70 zł Original price was: 24 590,00 zł30 245,70 zł.22 131,00 zł27 221,13 złCurrent price is: 22 131,00 zł27 221,13 zł. tax excl.with VAT

By default, prices include 23% VAT (Poland). The rate will be updated after entering the order details.

| Sizes: 1000x1000mm |

Shipping from warehouse: until working days

Every order is prepared with the utmost care.

Secure and convenient payments

Card, bank transfer, deferred payment – choose the best option for you.

Polish manufacturer

We manufacture locally – with care, precision, and responsibility.

Professional customer service

Call us: +48 573 568 355 or write to us in the chat – We'll help you!

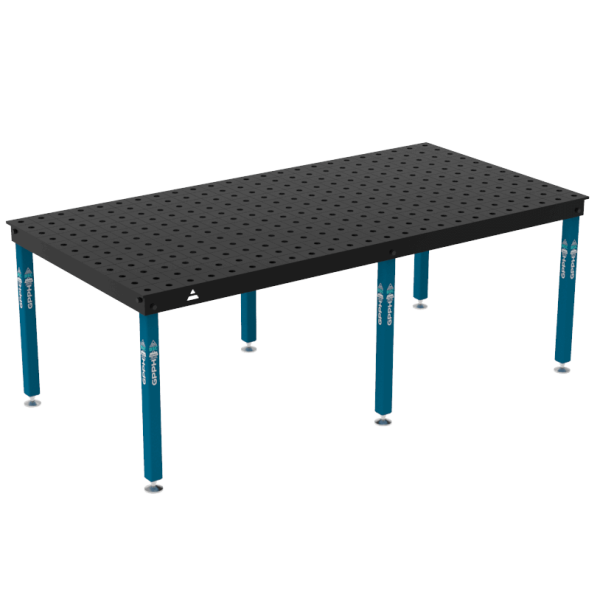

Welding tables can be used wherever precision is required during welding. You can use them for manual or robotic welding. Your structures will finally be made accurately, without unnecessary corrections!

It also ensures ergonomic and fast work while maintaining precision and repeatability of the structures.

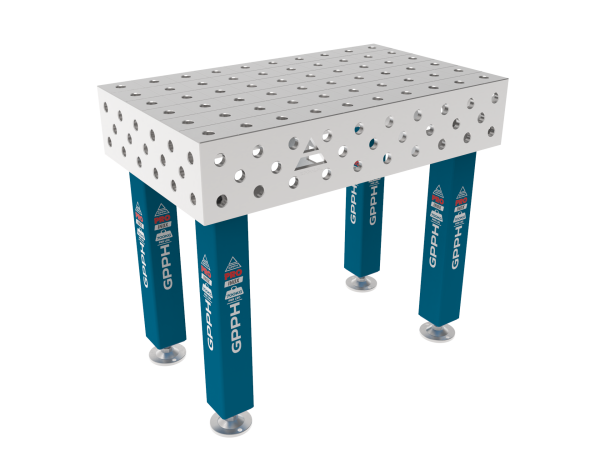

A Welding Table Must Be Flat! The PRO INOX table tops, with a thickness of 15 mm, feature dense ribbing that ensures a perfectly flat working surface. The 1000×1000 mm table is reinforced with 2 longitudinal ribs and 2 crosswise ribs. The table’s massive and rigid substructure guarantees maximum stability during use and protects the surface from deformation. The flatness tolerance across the entire surface is ±0.3 mm*.

|  |

Stainless Steel Welding Tables from the INOX series are made of stainless steel grade 1.4301, which offers better electrical conductivity than standard steel – electrical resistivity at 20°C = 0.73 (Ω mm²)/m. These tables are ideal for use wherever precise stainless steel welding is required.

Stainless steel welding tables are known for their high-quality craftsmanship and wear resistance. They are made from stainless steel with a high chromium content, which ensures durability and corrosion resistance. Thanks to GPPH INOX Welding Tables, you can weld stainless steel structures without the risk of iron contamination or the formation of corrosion spots.

It's up to you!

|  |

|  |

| |

Milled and chamfered holes in the table top facilitate easy assembly and disassembly of tools during your work, thanks to the holes being precisely matched to the tools. This also contributes to less wear and tear on the tools – you do not need to use a lot of force to assemble and disassemble them. This design is the best solution available on the market for welding tables! The tolerance of the welding table holes is ±0.05 mm.

The engraved scale on the table top consists of vertical and horizontal lines in a 100x100mm grid. It serves as a reference point when setting up the structure and mounting tools. Using measuring tools, you can position your structure correctly to achieve the required dimensions.

The legs of the PRO INOX Welding Tables, made from 100×100 mm profiles, have a load capacity of 700 kg per leg. For the 3000×1480 mm model, which is equipped with 8 legs, this gives you a total maximum load capacity of 5,600 kg.

You have a choice: leg with foot or on wheels – check which one is better for you!

For working on PRO INOX series Welding Tables, you can use precision-machined tools from the PRO series. They allow you to accurately build any flat 2D or spatial 3D structure — all in significantly less time!

*provided that the table is leveled correctly.

Stół Spawalniczy PRO INOX 15mm - 1000x1000mm

Stół Spawalniczy PRO INOX 15mm - 1000x1000mm

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

We’re sorry, but no reviews match your current filters.

GPPH S.C. © 2025 All rights reserved.

Podaj swój adres e-mail, aby zachować zawartość koszyka i wrócić do zakupów w dogodnym momencie.