- +48 573-568-355

- [email protected]

The promotion is valid in selected countries of continental Europe.

PROMOTION STILL ON FOR

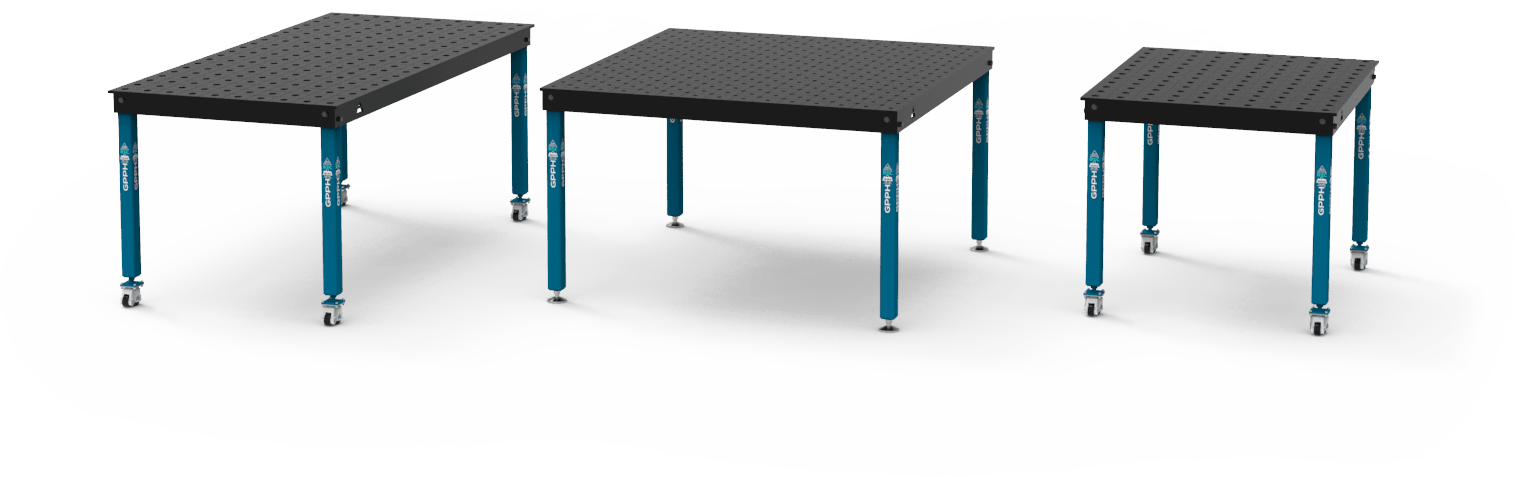

Are you looking for a Welding Table without side walls and the weight of your constructions does not exceed 1,500 kg? The BASIC Welding Table will meet your expectations and is also reasonably priced, allowing you to purchase additional tools without straining your budget.

The BASIC Welding Table will provide a perfectly flat working surface that is resistant to deformation. It owes this to its rigid and solid base with a height of 80mm. From now on, your welded structures will be straight, repeatable and distortion-free.

You will use the milled tools of the PLUS series to work on the BASIC welding tables. With these, you can accurately produce any 2D flat or 3D structure. And all this in considerably less time!

It does not matter whether you carry out your welding work in the classic manual manner or use welding robots - BASIC tables are the ideal choice!

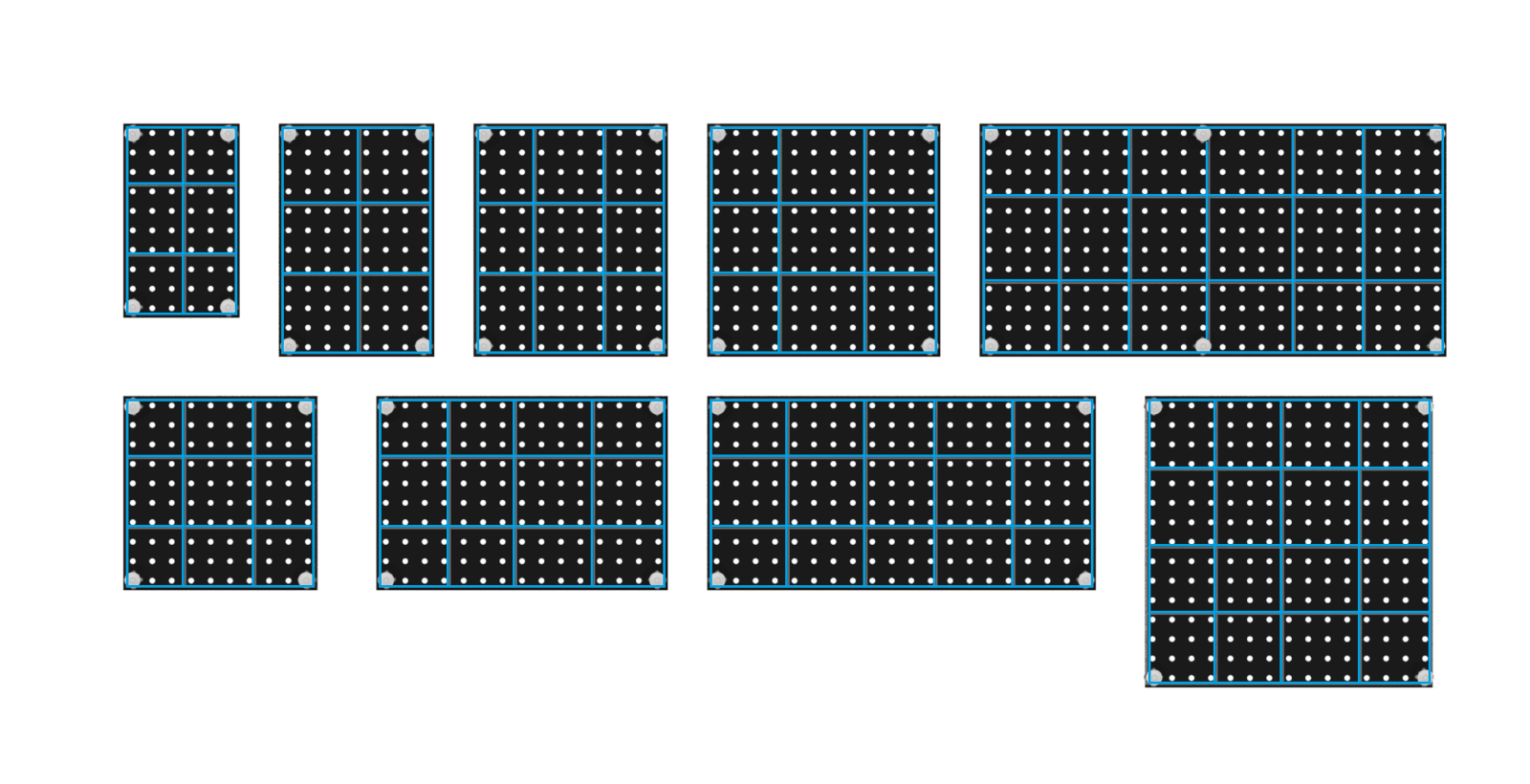

No matter what size structures you are welding - among the BASIC tables you will find up to 9 different sizes of welding tables, which are available in dimensions from 1000x600mm to 2400x1200mm.

If you are making large constructions, we suggest choosing the BASIC Table in the ⌀28mm hole system in a 100x100mm grid, while for light and precise work - the ⌀16mm hole system in a diagonal grid or in a 50x50mm grid. The choice is yours!

Where will you use the BASIC Welding Table? Anywhere where you need precision when welding. You will use it for manual or robotised welding. Your constructions will finally be made accurately, without unnecessary corrections! If you use a welding robot for your work, we have a great solution for you!

The BASIC Welding Table is perfect as a base for robotised welding and measuring stations. For such work, no side walls are used, so the BASIC Welding Table fulfils all your needs and at the same time is more cost-effective compared to traditional welding tables with side walls.

Using milled tools, you will build a suitable and easy-to-use working environment for repetitive flat as well as spatial structures.

The first of the presented applications of the BASIC Table is to make 2D flat structures - see how you can easily and quickly make a shelf for yourself or your customers! The honeycomb wall shelf is versatile, so it can be used in bedrooms, living rooms, but also as a decorative element in restaurants, for example. It can also function as a bookshelf.

Our next proposal, which you will make on the BASIC Welding Table, is a 3D spatial construction. With the right tools and a flat surface, the table legs will finally be straight and the whole thing stable.

On the BASIC Table you can weld not only profiles but also sheet metal parts. Our proposal is something for fans of tidiness in the workshop. A workshop trolley is the dream of many technicians, welders or mechanics, and now you can make one yourself with the BASIC Welding Table. See how easy it is!

The BASIC series welding table, like other GPPH welding tables, is characterised by a massive and rigid table top substructure, which guarantees the highest stability during use and protection against deformation.

Depending on your preferences, you can choose any size of BASIC Table in the hole system:

You decide!

A Welding Table must have holes – and the BASIC has them milled and chamfered! This design of the tabletop holes ensures easy assembly and disassembly of tools during your work, thanks to the precise fit of the holes to the tools. It also reduces wear – you don’t need much force for mounting or removing them. This is the best available solution on the welding table market!

Engraved tabletop grid consists of vertical and horizontal lines in a 100x100 mm pattern. It serves as a reference point when arranging structures and mounting tools. With measuring tools, you can correctly position your structure to achieve the desired dimensions.

The BASIC series of welding tables are characterised by::

A welding table has to be flat! The table top of the BASIC Table has dense ribbing, which results in a perfectly flat working surface. This ensures that the structures you weld will be even and accurate.

| Worktop dimensions | Net price |

|---|---|

| 1000x600 | € 760 |

| 1000x1000 | € 980 |

| 1200x800 | € 940 |

| 1200x1000 | € 1 060 |

| 1200x1200 | € 1 190 |

| 1500x1000 | € 1 220 |

| 1500x1480 | € 1 590 |

| 2000x1000 | € 1 490 |

| 2400x1200 | € 1 990 |

| Worktop dimensions | Net price |

|---|---|

| 1000x600 | € 860 |

| 1000x1000 | € 1 070 |

| 1200x800 | € 1 060 |

| 1200x1000 | € 1 190 |

| 1200x1200 | € 1 290 |

| 1500x1000 | € 1 340 |

| 1500x1480 | € 1 720 |

| 2000x1000 | € 1 640 |

| 2400x1200 | € 2 140 |

| Worktop dimensions | Net price |

|---|---|

| 1000x600 | € 932 |

| 1000x1000 | € 1 152 |

| 1200x800 | € 1 112 |

| 1200x1000 | € 1 232 |

| 1200x1200 | € 1 362 |

| 1500x1000 | € 1 392 |

| 1500x1480 | € 1 762 |

| 2000x1000 | € 1 662 |

| 2400x1200 | € 2 248 |

| Worktop dimensions | Net price |

|---|---|

| 1000x600 | € 1 032 |

| 1000x1000 | € 1 242 |

| 1200x800 | € 1 232 |

| 1200x1000 | € 1 362 |

| 1200x1200 | € 1 462 |

| 1500x1000 | € 1 512 |

| 1500x1480 | € 1 892 |

| 2000x1000 | € 1 812 |

| 2400x1200 | € 2 398 |

The BASIC Welding Table is available in the most popular systems and hole grids. This allows you to configure it according to your needs. Choosing the right system and grid does not limit you in your possibilities to create any welded structures!

Is the BASIC Welding Table ribbed? Of course! Every welding table should be ribbed. As with all GPPH Welding Tables, the ribs on the BASIC series are also laser-cut to ensure a perfect fit. The table's outer substructure is 10mm thick and the inner dense ribbing is 8mm thick. This reinforcement ensures that the table cannot be deformed, as well as that the welded structures are repeatable and maintain the dimensions set.

The dense ribbing of the table guarantees rigidity and maintains the flatness of the tabletop for many years. For example, in the BASIC table 1500x1000mm there are as many as 5 ribs, where in other tables of this type available on the market you can usually find a maximum of two ribs or none at all.

Legs are the basis! The BASIC Welding Table has them made of a 60x60 mm profile with a wall thickness of as much as 4 mm, which guarantees a load capacity of 250 kg per leg and makes the table structure stable and safe.

You have a choice: a leg with a foot or on a wheel - check which is better for you!

If you have one dedicated place in your workshop that you will use for the table and welding, we suggest choosing a table on adjustable feet. This solution allows you to reduce your investment costs or select more accessories or tools.

Your workshop changes depending on what you are currently welding and you have to move the welding table even several times during the day? Choose a BASIC table with a foot on the wheel! In less than a minute you will pick up the foot and, thanks to the wheels, move the table to the right place for you.

Fast assembly bolts mean quick and secure tool assembly. It is thanks to them that you can easily create tooling from tools to weld even the most complex spatial structures. The possibility of combining tools not only with the tabletop, but also with each other, offers unlimited possibilities.

Fast assembly bolts mean that tools can be quickly and securely attached to each other and to the table top. Magnetic assembly bolts, classic quick-mounting assembly bolts and universal adjustable assembly bolts are available for the BASIC welding table.

You can use them to connect tools to each other when welding 3D space structures.

Find out what you will use the different types of arbor for:

You will use the milled tools of the PLUS series to work on the BASIC welding tables. With these, you can accurately produce any 2D flat or 3D structure. And all this in considerably less time!

Using the milled tools, you will build a suitable and easy-to-use working environment for making repetitive flat as well as spatial constructions. Check out our suggestions for ready-made tool sets for the BASIC series of welding and assembly tables.

Order matters! And our tool cart will certainly help you maintain it. Depending on the number of tools you have, you can choose a small or large tool cart.

The large GPPH tool trolley will hold a tool kit for even the most demanding users! It will make your workspace more ergonomic than ever before and keep your GPPH tools organised and always within easy reach.

One of the many advantages of the small tool trolley, on the other hand, is that it fits under most dimensions of the GPPH Welding Tables, so it doesn't take up the space that is so valuable in every workshop, and all the tools are within easy reach when working!

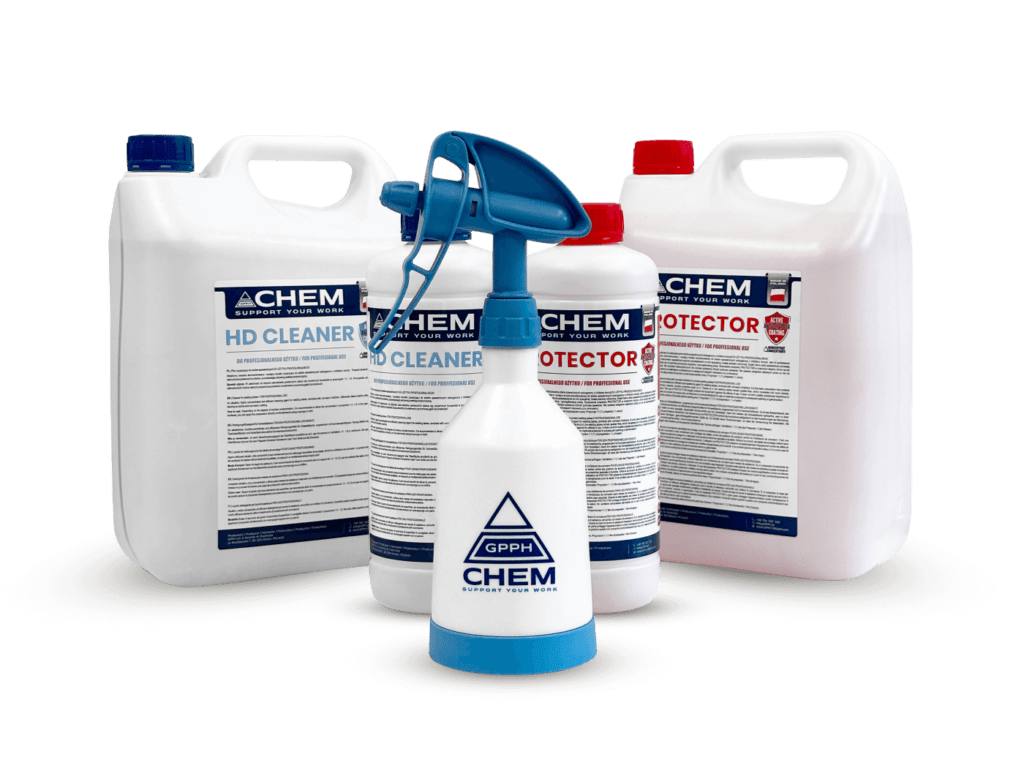

Welding table care is the key to its long life. Choose professional GPPH CHEM chemicals and enjoy effective work for many years. In our offer you will find special products that will provide appropriate protection and care for your welding table.

Protector is an anti-scratch concentrate that forms a durable and protective film to protect against welding spatter and corrosion. HD Cleaner, on the other hand, is a highly concentrated cleaning fluid that effectively removes tough dirt, leaving the table surface in impeccable condition.

Thanks to GPPH CHEM's professional products, your grinding and welding station will be in excellent condition, contributing to greater working efficiency and long-lasting use of this reliable equipment. Provide your stand with proper care and enjoy its durability and high quality for many years!

GPPH S.C. © 2025 All rights reserved.

Podaj swój adres e-mail, aby zachować zawartość koszyka i wrócić do zakupów w dogodnym momencie.