What are the benefits of investing in GPPH welding tables?

In today's fast-paced industrial world, precision, quality and efficiency are essential for success in any industry. When it comes to welding, accurate and robust joints are key to ensuring durability, safety and an excellent finish. That's why more and more welders and manufacturers are choosing to invest in GPPH welding tables, which offer a range of unique benefits for both novice and professional welders. Whether you work in the metal, automotive or aerospace industry, investing in welding tables from GPPH can help improve the quality of your welding process.

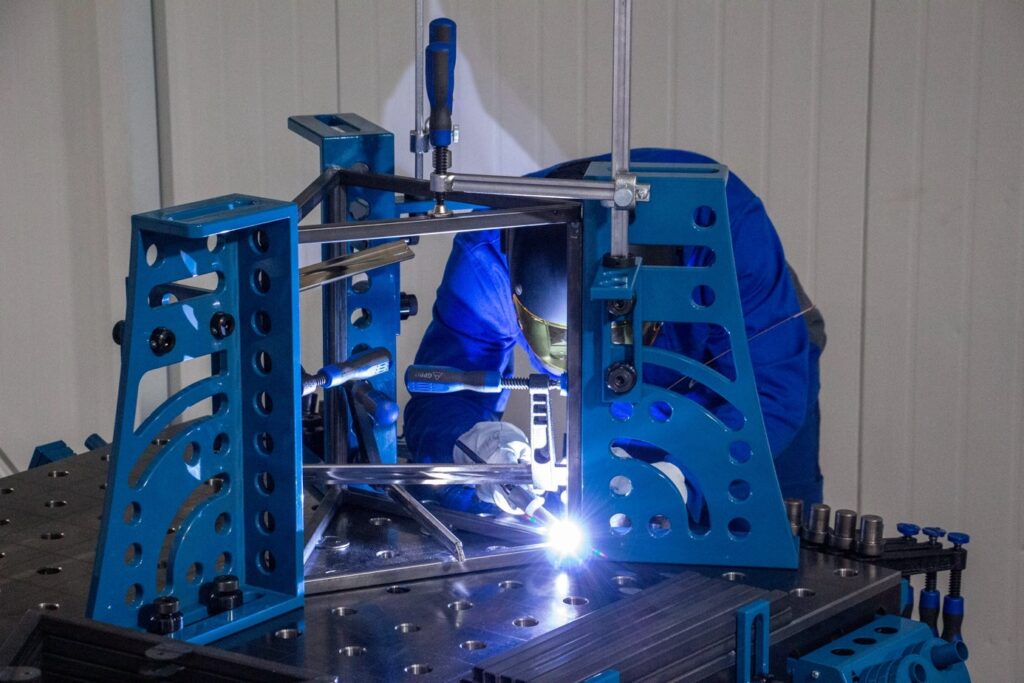

The first and extremely important benefit of investing in welding tables is increased precision. GPPH's welding tables have been designed with attention to the finest detail to provide a stable and flat working surface. This allows the welder to precisely position and align the welding materials, resulting in accurate and perfectly matched joints. GPPH weld tables enable construction with much greater precision and repeatability, which is key to achieving an excellent finish and aesthetics in the final product.

Another benefit of investing in GPPH's welding tables is the increase in precision and quality. Thanks to the stable work surface, welders can precisely control the welding process, which largely results in excellent quality welded joints. The welds are even, aesthetically pleasing and free from defects. This not only adds to the aesthetic value of the products, but is also important for their durability and strength.

Productivity is another aspect that can be significantly improved through the use of welding tables. The ability to precisely position the workpieces to be welded and the stability of the work surface speed up the welding process and minimise the time needed for corrections and adjustments. This translates into increased productivity, reduced costs and increased competitiveness.

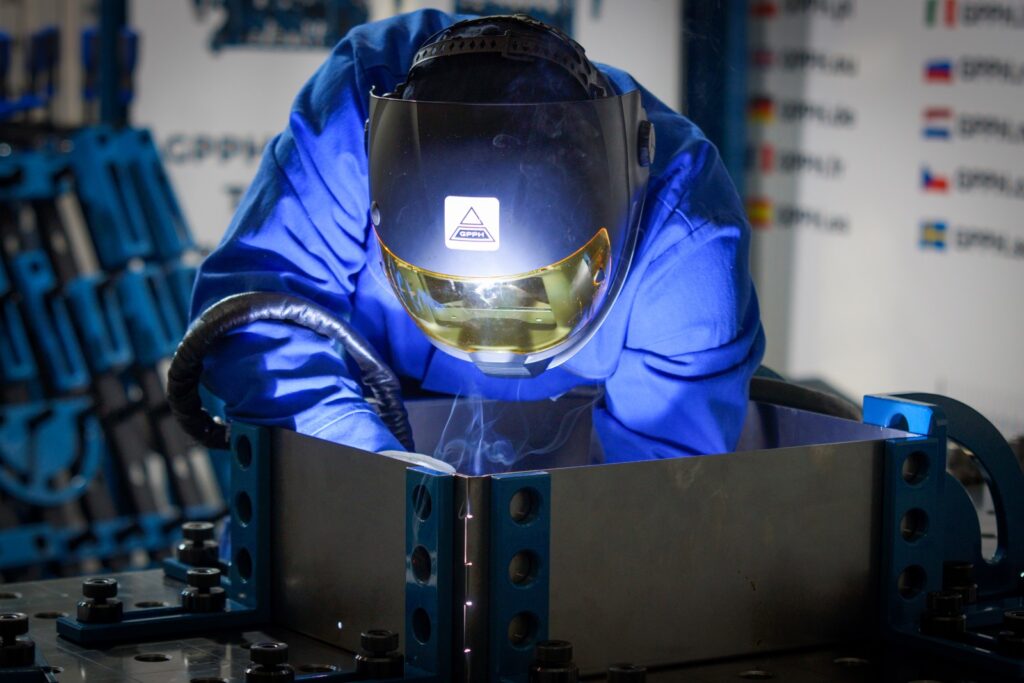

An important aspect that cannot be overlooked is the safety of the welder while working. GPPH welding tables are designed to eliminate the risk of injuries and accidents. Their robust designs protect welders from dangerous situations. This gives welders confidence and allows them to focus on making welds safely and efficiently.

In summary, investing in GPPH welding tables brings a number of benefits. Stability, surface flatness and the ability to position materials precisely translate into the creation of excellent structures with high quality and aesthetics. Improved productivity and safety, thanks to adapted ergonomics, translates into greater work efficiency and reduced occupational risks. Therefore, an investment in GPPH welding tables is extremely valuable for professional welders and manufacturers who aim to achieve excellent results and increase competitiveness in the market.