Welding is a profession that offers more than just stable employment – it is a skill that combines precision with craftsmanship, and the result of the work are structures that truly matter. More and more people, both young and those looking to change careers, are wondering how to enter this field. The path to becoming a welder does not have to be complicated – all it takes is some determination, proper training, and good learning tools.

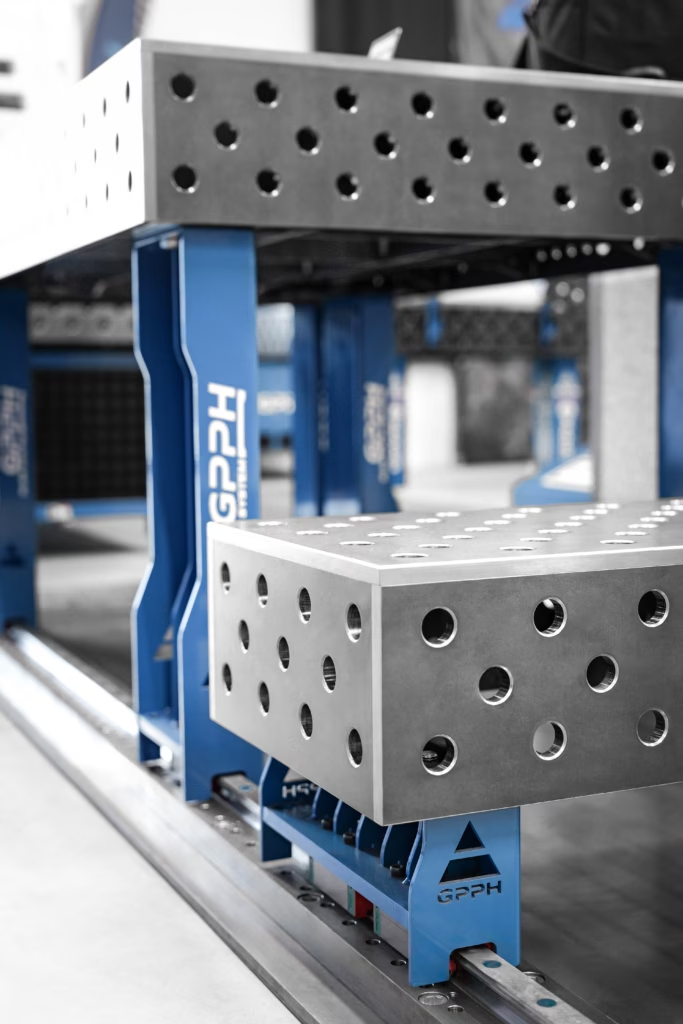

The first step is gaining the basics – preferably at a vocational school, technical school, or a professional welding course. During theoretical classes, you learn the differences between MIG/MAG, TIG, and MMA methods, safety rules, and how to prepare materials. But real learning begins only when you pick up the torch and weld your first bead. At this point, the workstation is extremely important – it must be stable, safe, and suited for learning. A good GPPH welding table allows beginners to develop proper habits from the very start. Its work surface has a flatness tolerance of ≤ 0.3 mm across the entire tabletop, ensuring perfect evenness and stable working conditions. The mounting holes are milled and chamfered, allowing accessories to fit precisely and without play. These are small details that make a big difference in learning how to weld.

Good advice no. 1: already at the course stage, get used to working in conditions similar to those you will encounter in a workshop or industrial facility. Do not weld “on your knee” or on random surfaces – precision and ergonomics must be learned from the very beginning. A solid worktable, such as those from GPPH, will help you develop good habits and work in safe positions, which will translate into the quality of your welds and your health in the future.

The next stage is obtaining certifications – after completing a course and passing the exam, you can legally work in the profession. However, real experience comes with practice. Beginner welders usually start with simple structures, learning how to plan their work, select parameters, and control weld quality. Here as well, it is worth paying attention to workstation organization. Many professionals emphasize that order and ergonomics are half the success. This is exactly why GPPH welding tables are so highly valued – they can be expanded with various accessories such as angle brackets, stops, or clamps, which help with quick and precise positioning of components. This allows every detail to be set exactly as needed, translating into the quality of the finished weld and workplace safety.

Over time, a welder begins to work on larger projects where repeatability and precision matter. At that point, a well-planned workstation becomes the foundation of efficiency. GPPH solutions were created with every stage of a welder’s development in mind. The tables are available in various sizes and configurations, and thanks to TRESLE welding supports and the SLIDE SYSTEM, it is possible to create workstations that can be easily adapted to current needs and the type of structures being produced. These are flexible solutions that allow the workspace to be expanded as experience grows – from the first attempts to advanced work in an industrial workshop.

Good advice no. 2: invest in learning, but also in your work environment. Even the best technique won’t replace order, comfort, and safety. If your workstation is well organized – everything is within reach, parts are securely clamped, and the work surface doesn’t require constant adjustments – you work faster, more accurately, and with greater satisfaction. This is exactly what well-designed GPPH equipment helps with: it makes not only welding easier, but also maintaining order and repeatability in your work.

The welding profession is a trade with a future. Skilled specialists are in short supply, and those who can combine knowledge with precision can count on truly good working conditions. That is why it is worth investing not only in courses and certifications, but also in equipment that supports daily skill development. Because learning to weld is not just theory – it is also the environment that helps work safely and with precision. GPPH has been supporting welders on this path for years, delivering solutions that make learning easier, improve work organization, and help achieve professional satisfaction. After all, every good welder knows that a precise weld starts with a well-prepared workstation.