How do GPPH welding table tools increase precision and productivity?

In welding, precision and efficiency are key factors determining the final result. GPPH, a leading manufacturer of welding tools, provides solutions that set new standards in this field. In this article, we will look at how GPPH's specialised tools and accessories for welding tables improve welding quality through stable clamping of components.

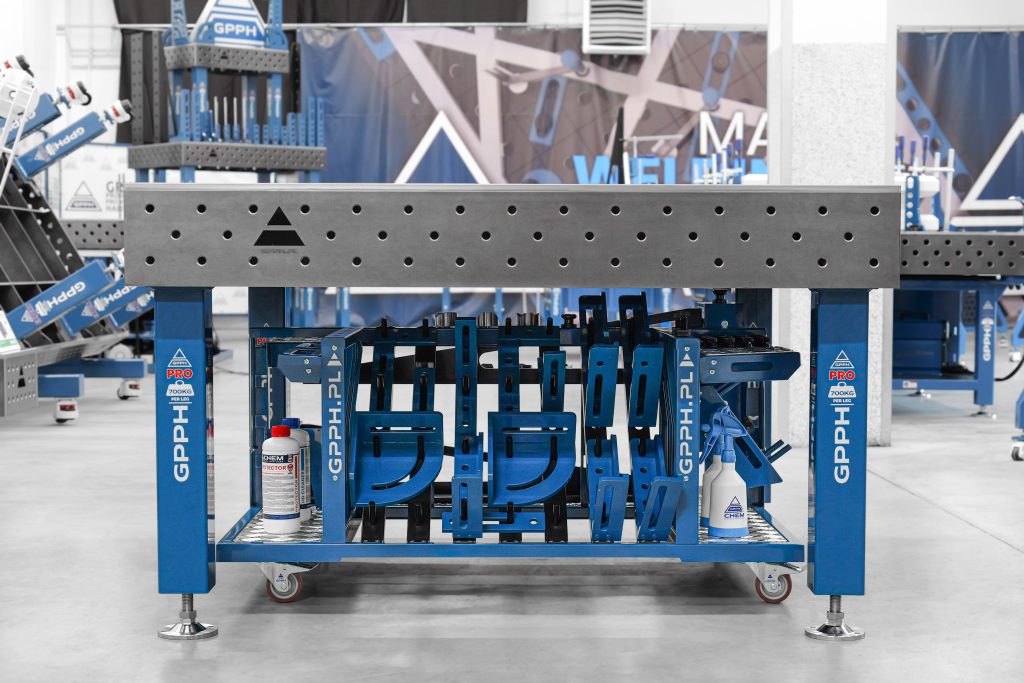

M tool trolley under welding table from the PRO series

Stable clamping – the foundation for precise welding

One of the most important aspects in welding is the secure and stable clamping of the workpieces.

- Welding clamps: They allow for secure immobilisation of the material, eliminating the risk of movement during welding.

- Stoppers and angle brackets: Enable precise positioning of components at any angle and in any position.

GPPH tools allow welders to focus on the precise execution of the structure, guaranteeing the stability of the fastened elements.

Versatility of GPPH tools

GPPH tools and accessories are designed for a wide range of applications.

- Increasing working surface: Blocks, welding supports or table extensions allow you to adapt the working surface to the specific requirements of your project.

- Specialised accessories: Such as angle brackets, stoppers and pins, they support the implementation of even the most complex tasks.

Thanks to their versatility, GPPH tools are indispensable in many sectors of the welding industry.

Design with tools on the GPPH welding table

Increased work efficiency

Improving the welding process directly translates into savings in time and resources.

- Quick setup: Easy tool assembly significantly reduces setup time.

- Elimination of corrections: Stable mounting reduces the number of errors and the need for corrections.

As a result, productivity increases and operating costs are reduced.

Durability and reliability

GPPH tools are made of high-quality materials, which guarantees their long service life.

- Damage resistance: The robust design ensures durability even in harsh operating conditions.

- Precise workmanship: Manufacturing accuracy translates into tool reliability.

Durable tools are an investment that saves money in the long run.

Work safety

The use of appropriate tools also improves safety in the workplace.

- Accident risk reduction: Stable components minimise the risk of uncontrolled material movements.

- Ergonomic design: Tools designed for working comfort reduce physical strain on the welder.

Ensuring a safe working environment is crucial for achieving high efficiency and quality.

Why choose GPPH tools?

- Innovation: Continuous development and implementation of new technologies.

- Technical support: Professional advice and after-sales service.

- Customisation: Tools and accessories can be individually configured.

In summary, GPPH welding table tools are an investment in quality, precision and work efficiency. Thanks to their stable mounting, versatility and exceptional durability, work becomes more effective and satisfying. If you want to raise the standards in your workshop, be sure to check out the GPPH range.