- +48 573-568-355

- [email protected]

The promotion is valid in selected countries of continental Europe.

PROMOTION STILL ON FOR

In welding, precision and stability are key to the success of any project. The right tools and accessories not only make work easier, but also affect the quality of the finished structure as a whole. TRESTLE welding supports are a solution that combines durability, versatility and a variety of versions tailored to individual user needs.

In the fast-paced world of welding and assembly, comfort and efficiency are crucial. GPPH's Relevating XWT welding table is a breakthrough solution that provides exceptional ergonomics, improved safety and reduced worker fatigue with its height-changing function. Find out how this innovative tool can elevate your work quality and efficiency to a whole new level.

In the world of welding, the right tools are fundamental to the success of any project. The DIY welding and assembly table GPPH is a solution that combines stability, mobility and versatility to offer users unparalleled benefits in their daily work. Find out why this table is an excellent investment for professionals and welding enthusiasts alike.

Nowadays, cost optimisation is the key to success in any industry. The cost-effective GPPH SMART welding tables are the perfect option for those who want to make smart investments without sacrificing quality and functionality. How reducing investment costs can affect...

In the world of welding and assembly, the right tools are crucial to ensure efficiency and safety. The BASIC welding and assembly table from GPPH is a solution that significantly improves daily tasks in both professional workshops and home projects.

Zakład Ubezpieczeń Społecznych (ZUS) ponownie ogłosił nabór wniosków o dofinansowanie projektów mających na celu poprawę bezpieczeństwa i higieny pracy w firmach. W ramach tego programu przedsiębiorcy mogą uzyskać nawet 80% dotacji na zakup maszyn i urządzeń. Nabór wniosków na 2025 rok odbędzie się w terminie od…

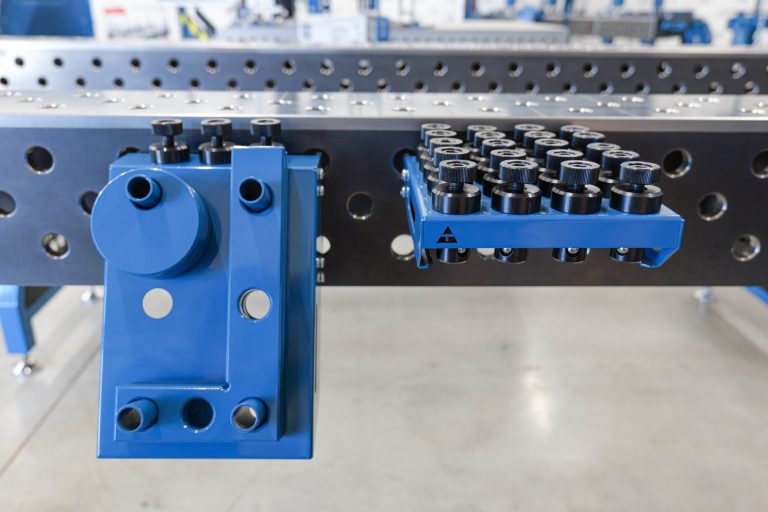

Today's welding workshops require not only qualified staff, but also equipment and accessories of the highest quality. GPPH welding tables, combined with dedicated tools, create a solid foundation for efficient and precise work. Let's take a closer look at GPPH tools and accessories that simplify the welding and assembly process, making it more efficient.

Every workshop needs excellent organisation, quick as well as easy access to tools in order to function efficiently. GPPH tool trolleys are the ideal solution to help you stay organised, improve efficiency and save valuable time. Here are the key features that make these trolleys an invaluable support in any workshop!

Deciding on the right welding table for your workshop is a decision that affects the efficiency, comfort and quality of your work. Both economical and traditional welding tables offer a variety of advantages, differing in terms of cost, functionality and durability. In this article, we'll take a look at both solutions to help you...

EXPERT welding tables are the perfect choice for advanced workshops that need equipment that provides the highest quality, durability and precision. Each table in the range has been designed for intensive work with ergonomics and safe use. Here are the key features that.

GPPH S.C. © 2025 All rights reserved.

Podaj swój adres e-mail, aby zachować zawartość koszyka i wrócić do zakupów w dogodnym momencie.