Why it is worth having a mobile welding workstation – advantages and disadvantages.

Modern welding is increasingly less associated with a single, permanently assigned workplace. The dynamics of orders, the variety of structures, and the need for flexibility mean that mobile welding workstations are gaining popularity – both in small workshops and in large manufacturing plants. But is mobility always an advantage? Let’s find out.

What is a mobile welding workstation?

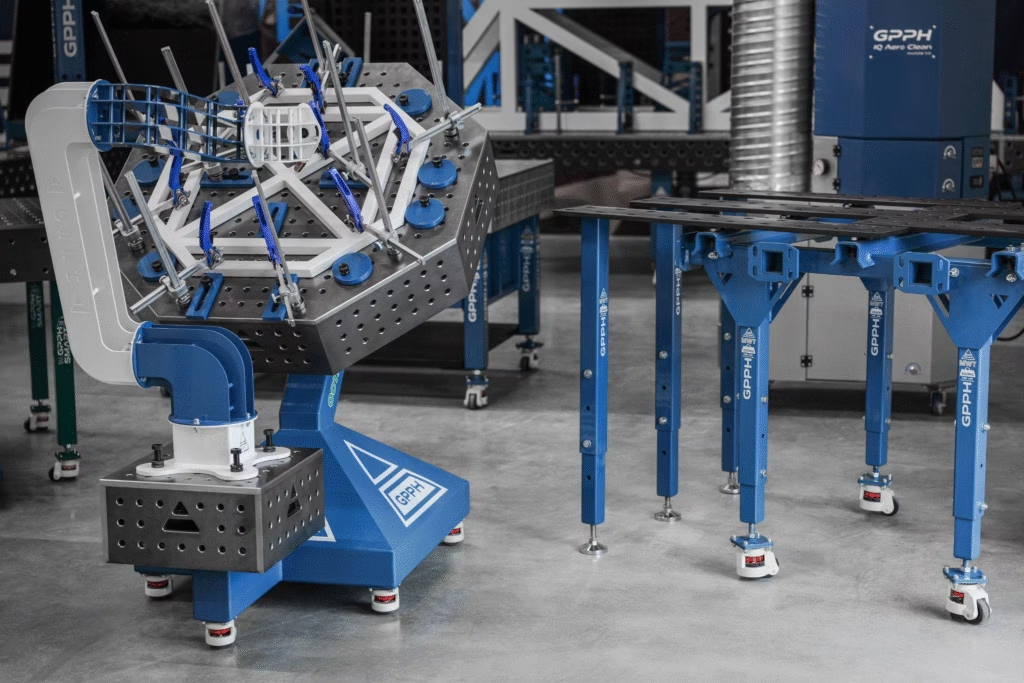

Simply put, a mobile welding workstation is a workstation that can be easily moved, configured, and adapted to current work needs. In practice, this can include welding tables on wheels that allow quick changes to the workshop layout, modular tables enabling flexible expansion of the working surface, as well as SLIDE SYSTEM rail systems that facilitate fast positioning of components and tools. The setup is often complemented by TRESTLE welding supports, which stabilize large structures, and mobile fume extraction systems that improve air quality without the need for permanent installation. One thing is key: the workstation operates where it is currently needed – not the other way around.

Advantages of a mobile welding workstation

- Work flexibility

A mobile workstation allows you to respond quickly to changes. Welding small components today and large structures tomorrow? Thanks to welding tables on wheels or modular GPPH solutions, you can easily rearrange your workshop without lifting heavy elements. - Time savings

Instead of moving the material to the workstation, you move the workstation to the material. This makes a huge difference when working with large and heavy structures. Mobility genuinely shortens preparation time and increases efficiency. - Better workplace organization

Better workplace organization WeldStation, combine a worktop, drawers, shelves, and tool panels. Everything is within reach, and order translates into safety and working comfort. - Ergonomics and welder’s health

The ability to place the workstation where access, lighting, or ventilation is optimal provides real support for health. Additionally, height-adjustable tables or workstations with height regulation allow the working position to be adapted to the user, not the other way around.

Disadvantages of mobile welding workstations – what is worth keeping in mind?

- Stability – if mobility is poorly designed

Cheap, improvised solutions may be associated with a lack of rigidity. That is why it is crucial for a mobile workstation to be designed from the ground up specifically for welding – a solid structure, appropriate load capacity, and lockable wheels are absolute essentials. With professional GPPH welding tables, mobility does not mean a compromise in stability. - Higher initial cost

Mobile solutions are usually more expensive than the simplest stationary table. However, it is worth looking at them as an investment – time savings, better organization, and greater flexibility quickly start to “pay back” the costs. - Mobility does not forgive improvisation

A mobile welding workstation works well only when it is well thought out. If the tools are random, components have no proper support, and the structure is “hanging in the air,” every change of setup becomes a problem. Unlike a fixed workstation, mobility quickly exposes organizational flaws and, instead of making work easier, starts to slow it down. The good news is that this drawback can be completely eliminated. - proper workstation organization makes mobility a real advantage rather than an obstacle.

Mobility in practice – when does it really make sense?

A mobile welding workstation works best where the scope of work changes frequently and structures do not always fit into a single pattern. It truly makes sense when:

- you carry out a wide range of projects, from small components to larger structures, and need to change the workstation setup quickly without downtime,

- you work with large or awkward-sized components, whose transport to a fixed workstation is time-consuming or simply uneconomical,

- you operate in a limited workshop space, where the ability to reposition the table or the entire workstation allows for better use of the available area,

- you care about ergonomics and safety, meaning stable support for components, organized tools, and working in comfortable conditions – regardless of where the structure is being built.

Thanks to tables on wheels, welding supports, and modular solutions, mobility is no longer a compromise and starts to genuinely support everyday work. In a well-designed workstation, it is not the welder who adapts to the space, but the space that adapts to the task at hand.

Summary

A mobile welding workstation is not a passing trend, but a response to real working conditions in modern welding. With thoughtful configuration and solid construction, its advantages clearly outweigh its drawbacks. At GPPH, we have been designing solutions for years with one goal in mind: to improve the welder’s work – regardless of production scale or the type of structures being built.