Welding on a welding table for beginners: a comprehensive guide

Welding is a craft that requires precision, practice and the right equipment. For novice welders, starting on a welding table that provides a stable and reliable workspace is conducive to developing welding skills. This guide looks at basic techniques and tips for welding on a welding table.

Introduction to welding on a welding table

The welding table is a flat, stable surface designed specifically for welding tasks. It provides a safe and adjustable platform that guarantees precision and safety when welding. High-quality welding tables, such as those we manufacture, offer precision welding tops that are ideal for beginners and experienced welders alike.

Basic skills for beginner welders

- Understanding welding techniques: The first step in welding is to understand the different types of welding processes, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas) and covered electrode welding. Each type has its own applications, advantages and techniques.

- Safety first: Welding involves high temperatures, UV radiation and hazardous fumes. Always wear appropriate personal protective equipment (PPE), including a welding visor, flame-resistant gloves and long-sleeved shirts.

- Reading plans and diagrams: It is essential to understand how to read and interpret welding plans and diagrams. These documents provide detailed instructions on the types, positions and weld specifications required for the project.

- Preparing the material: Clean metal surfaces to remove dirt, rust or oil. Proper preparation ensures better weld quality and prevents contamination of the weld pool.

First steps on the welding table

- Setting up the welding table: Position the welding table in a well-ventilated area to avoid inhaling harmful fumes. Make sure the table is level and secured to prevent any movement during welding.

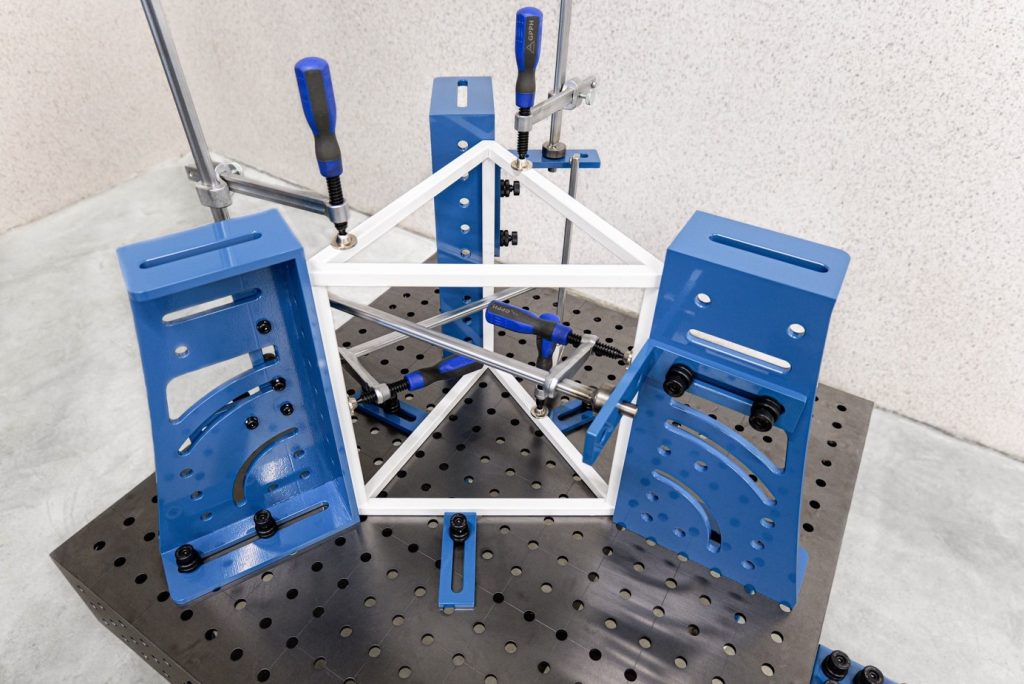

- Securing workpieces: Use clamps and pins to hold workpieces firmly in place. GPPH welding tables allow precise and secure positioning of materials. This configuration is crucial for maintaining accuracy and stability during welding.

- Adjustment of the welding machine: Adjust the welder according to the type of welding to be performed. Adjust parameters such as voltage, current and wire feed speed according to the thickness and type of metal. The right settings are crucial to achieving strong, clean welds.

- Practice makes perfect: Start by practising welding on scrap metal to familiarise yourself with the process. Focus on controlling the welding torch, maintaining a constant speed and achieving a stable weld stitch.

Basic welding techniques

- Stitch welding: Start by tack welding workpieces together. Tack welds are small welds that hold workpieces in place and prevent them from moving during the final welding process.

- Butt joints: This is a common welding technique where two pieces of metal are joined edge to edge. Make sure the edges are aligned and use clamps to hold them in place. Apply the weld along the seam, keeping a steady hand and constant speed.

- Finish welds: Fillet welds join two pieces of metal at right angles. This type of weld is commonly used for welding metal structures and frames. Place the pieces securely on the welding table and run the weld stitch along the joint, ensuring good penetration and a smooth finish.

- Weld stitch control: Practice maintaining a consistent arc length and travel speed. Consistent welding fixture control ensures even weld stitches and reduces the likelihood of defects.

Common challenges and solutions

- Welding spatter: Excessive welding spatter can be minimised by adjusting welding parameters and ensuring clean working surfaces. GPPH welding chemistry significantly helps to reduce the build-up of spatter on the welding table and workpieces.

- Distortion: The heat of welding can cause warping or distortion of the metal. To prevent this, use clamps to hold the parts in place and weld in a sequence that distributes heat evenly. Preheating the metal can also reduce the risk of distortion.

- Porosity: Weld porosity is caused by trapped gases. Adequate shielding gas coverage must be provided and metal surfaces must be thoroughly cleaned to avoid contamination. Adjusting the gas flow rate can also help to reduce porosity.

- Cracking: Cracking of welds can occur due to improper welding techniques or incompatible materials. Use a suitable filler metal and heat thicker materials to reduce the risk of cracking. Maintain a constant, controlled welding speed to ensure a solid weld.

Summary

The welding table offers beginners a stable and efficient platform to develop their welding skills. By following the basic steps and techniques above, beginners can build a solid foundation in welding, paving the way for more advanced techniques and complex projects. With practice, attention to detail and the right equipment, anyone can become proficient at welding on a welding table. Investing in a quality welding table, provides a reliable and precise foundation for any welding project.