- +48 573-568-355

- [email protected]

The promotion is valid in selected countries of continental Europe.

PROMOTION STILL ON FOR

The GPPH grinding/welding station is an excellent solution that effectively captures and removes dust and gases generated during grinding with a manual grinder and welding/welding work. It is an indispensable tool for professional welders, which ensures safety and comfort at work.

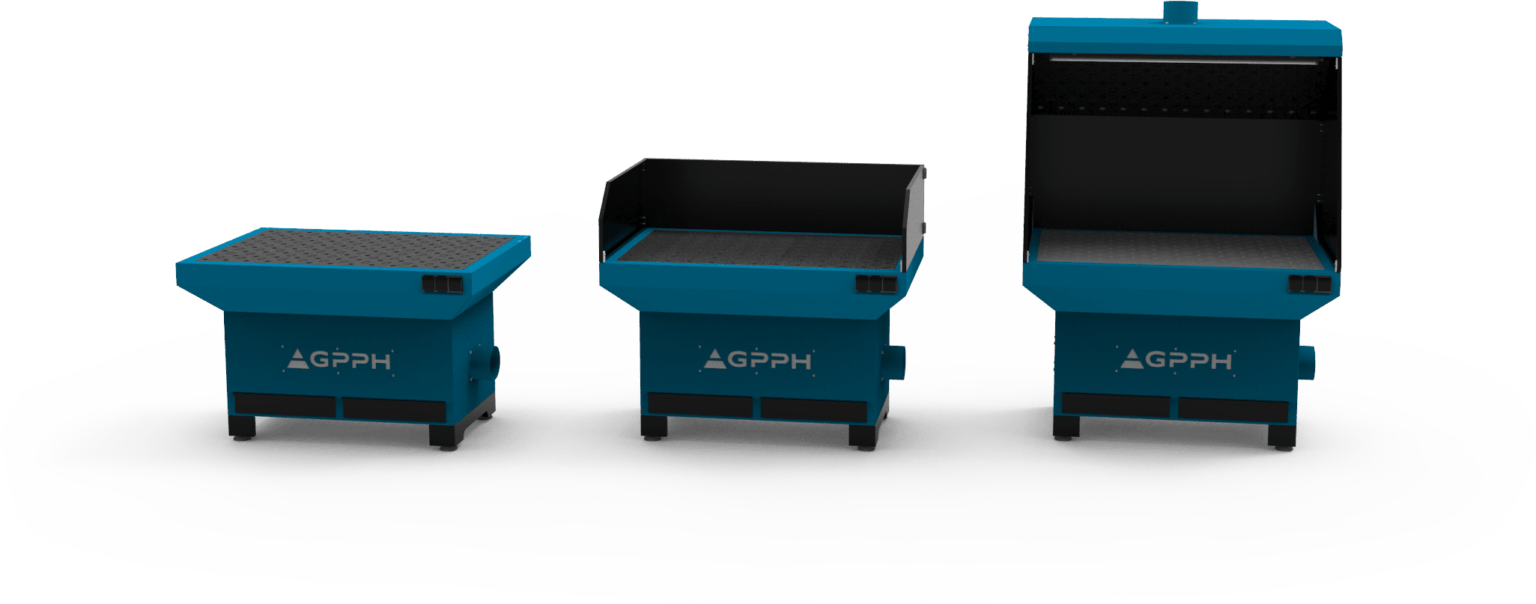

The grinding and welding station can be purchased in 3 variants:

The base of the station is adapted to the installation of guards and a top extraction set. Each version of the grinding and welding station consists of a working table with a top made of 8 mm thick metal sheet.

The guarded and top extraction versions of the sanding and welding workstation are equipped with hinged doors on both sides, making it practical to place larger workpieces on the table. In addition, each version has a powerful extraction sump with drawers, two 230V sockets for connecting power tools and an installation for connecting lighting, making the workplace well-organised and functional.

The GPPH grinding/welding stand features a robust construction for long-term durability. A top made of 8 mm thick sheet metal guarantees a stable and even working surface. The availability of this product in two dimensions, 1270x770 mm and 1870x770 mm, allows customisation.

With a GPPH grinding and welding station, your workplace will not only be efficient, but also safe and tidy. Bring order to your work and take advantage of the advanced solutions offered by GPPH that will enable you to focus on the most important thing - getting your jobs done perfectly.

The GPPH grinding and welding stand is a versatile tool that will find use in a variety of welding and grinding jobs. Have you wondered what these jobs are and where this functional stand is worth using? Let us introduce you to its potential applications!

Whether you work in heavy industry or a locksmith workshop, the GPPH grinding and welding station is the perfect support for your work. It allows you to perform various tasks precisely, safely and efficiently, ensuring the highest quality of workmanship on your projects. Keep your workshop or shop floor professional and tidy with the GPPH grinding and welding station!

The GPPH grinding and welding station is a complete solution that meets the needs of professional welders and locksmiths. It is a functional and efficient tool that enables precise grinding and safe welding of parts, while keeping the workplace clean and tidy.

Main features and advantages of the GPPH grinding and welding station:

Thanks to its advanced solutions and robust construction, the GPPH grinding and welding station is an invaluable aid to the daily work of welders and locksmiths. It allows you to achieve the highest quality welds, precise finishes and keep your workplace tidy. Choose the GPPH grinding/welding station and get a professional tool that meets your highest requirements!

The GPPH grinding and welding station comes in three variants, each with its own specific application:

All versions of the GPPH grinding and welding station have one thing in common - excellent build quality and durability. Thanks to their robust construction and advanced solutions, these workstations are not only reliable tools, but also guarantee safety and comfort. Choose the right version of the GPPH grinding and welding workstation, tailored to your needs and requirements, and enjoy professional support for your daily welding and grinding tasks.

The GPPH grinding/welding station is a versatile tool that enables the capture and removal of dust and gases generated during grinding and welding work.

It is the ideal solution to ensure safe and ergonomic working conditions.

The table shows the technical parameters of all versions and dimensions of the GPPH grinding and welding station.

| 1270x770mm | 1870x770mm | |

|---|---|---|

| BASE | $ 3 040 | $ 4 640 |

| BASE WITH GUARDS | $ 3 420 | $ 4 820 |

| BASE WITH TOP EXHAUST | $ 4 120 | $ 5 890 |

| Table | 1270x770 mm | 1870x770 mm |

|---|---|---|

| BASE | ||

| Weight | 167 kg | 225 kg |

| Resistance of flow | 250 Pa | 250 Pa |

| Recommended airflow | 1220 m³/h | 1220 m³/h |

| Maximum airflow | 2440 m³/h | 2440 m³/h |

| BASE WITH GUARDS | ||

| Weight | 190 kg | 250 kg |

| Resistance of flow | 250 Pa | 250 Pa |

| Recommended airflow | 1220 m³/h | 1220 m³/h |

| Maximum airflow | 2440 m³/h | 2440 m³/h |

| BASE WITH TOP EXHAUST | ||

| Weight | 264 kg | 315 kg |

| Resistance of flow | 250 Pa | 250 Pa |

| Recommended airflow | 2440 m³/h | 2440 m³/h |

| Maximum airflow | 4880 m³/h | 4880 m³/h |

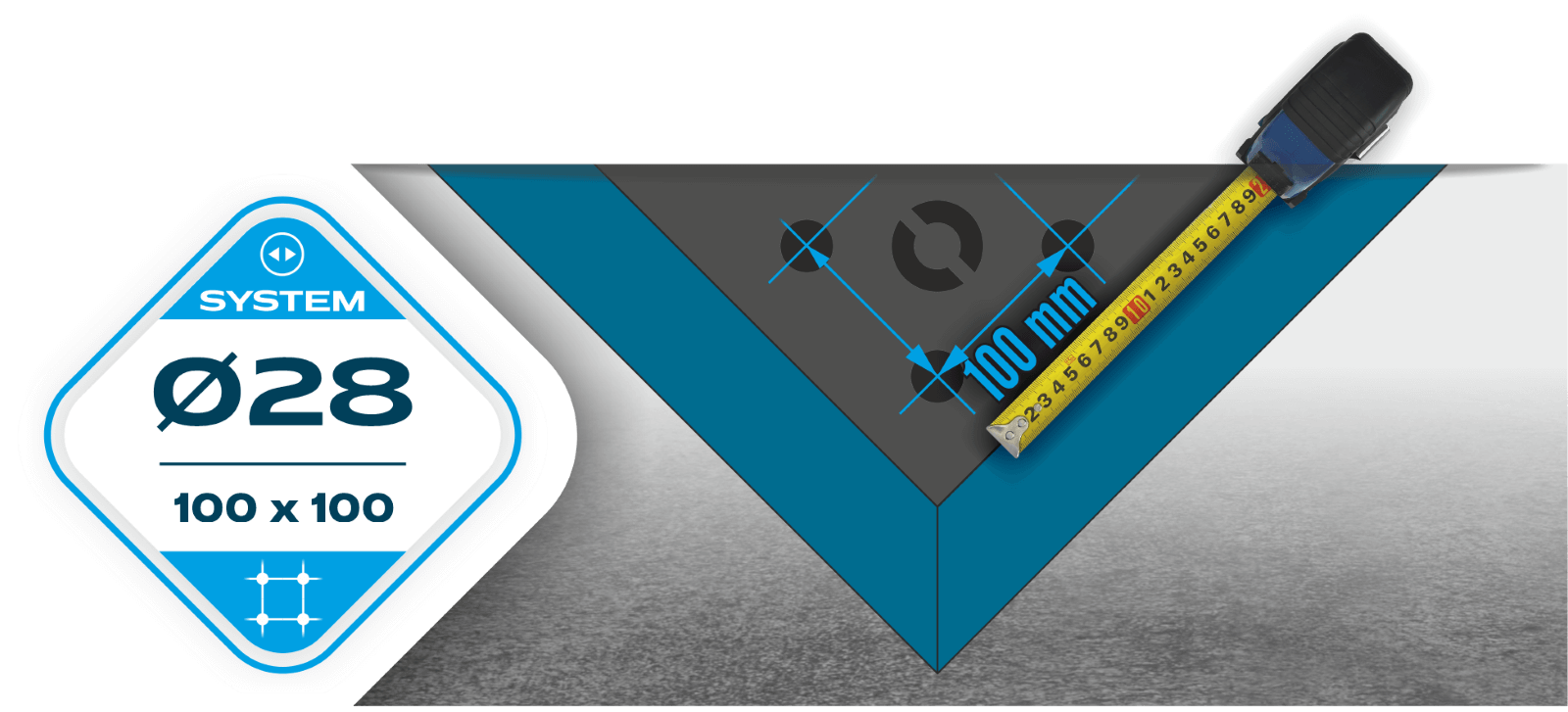

The grinding-welding workbench top is equipped with precisely positioned mounting holes of ⌀28 mm in a 100x100 mm grid. As a result, the user is free to mount different types of tools and other accessories in any position on the table, which significantly increases the efficiency of the work.

In addition, the worktop is equipped with holes for the extraction of dust and gases generated during grinding or welding. As a result, the environment is free of harmful substances and the user is assured of healthy and comfortable working conditions.

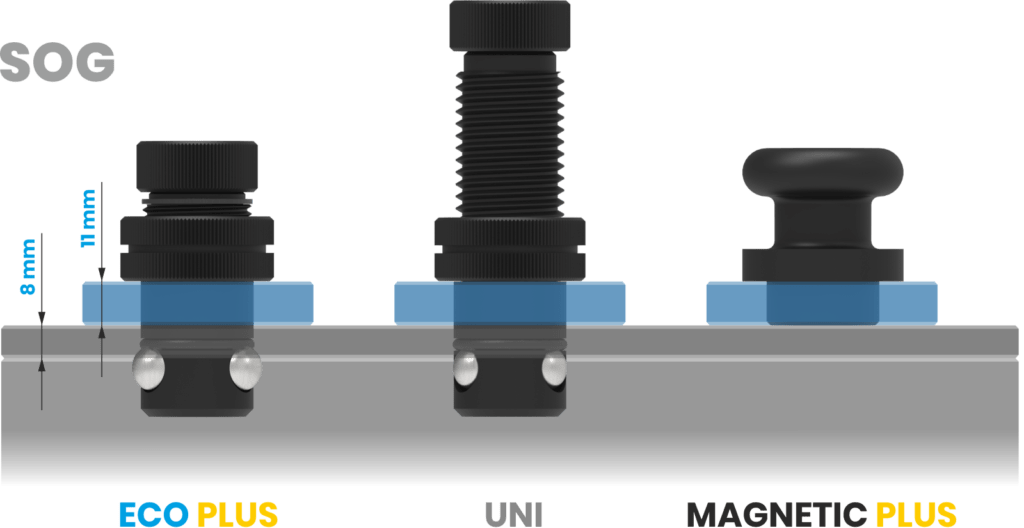

Fast assembly bolts are tools that make it significantly easier to mount tools quickly and securely. In our grinding and welding station, you will use the ECO/PLUS 19-22 quick mounting arbor to mount them, which is ideally suited to tools from the PLUS series.

We offer different types of mounting mandrels, such as magnetic assembly bolts, classic quick-mounting assembly bolts and adjustable universal assembly bolts. Each of these assembly bolts types has its own application, allowing you to optimise the tool assembly process and achieve the best results.

If you want to fix tools anywhere, not just in the holes of the welding table, then magnetic assembly bolts will be the ideal solution. With them, you make the most of the available work surface.

On the other hand, if you need to fasten tools together quickly and securely or attach them to a table, the classic quick-assembly bolts are perfect. With them, you will speed up the assembly process and achieve exceptional working efficiency.

Adjustable universal assembly bolts are suitable for clamping tools of different thicknesses. In addition, they allow three tools to be clamped simultaneously at a single point and are ideal for supporting welded spatial structures.

Use the milled tools of the PLUS series for your grinding and welding workstation and raise its quality to a higher level. Your flat and spatial constructions will be ready faster than ever before!

Make your work easier and more efficient. Discover our PLUS series of ready-to-use tool sets and create repeatable flat and spatial designs effortlessly.

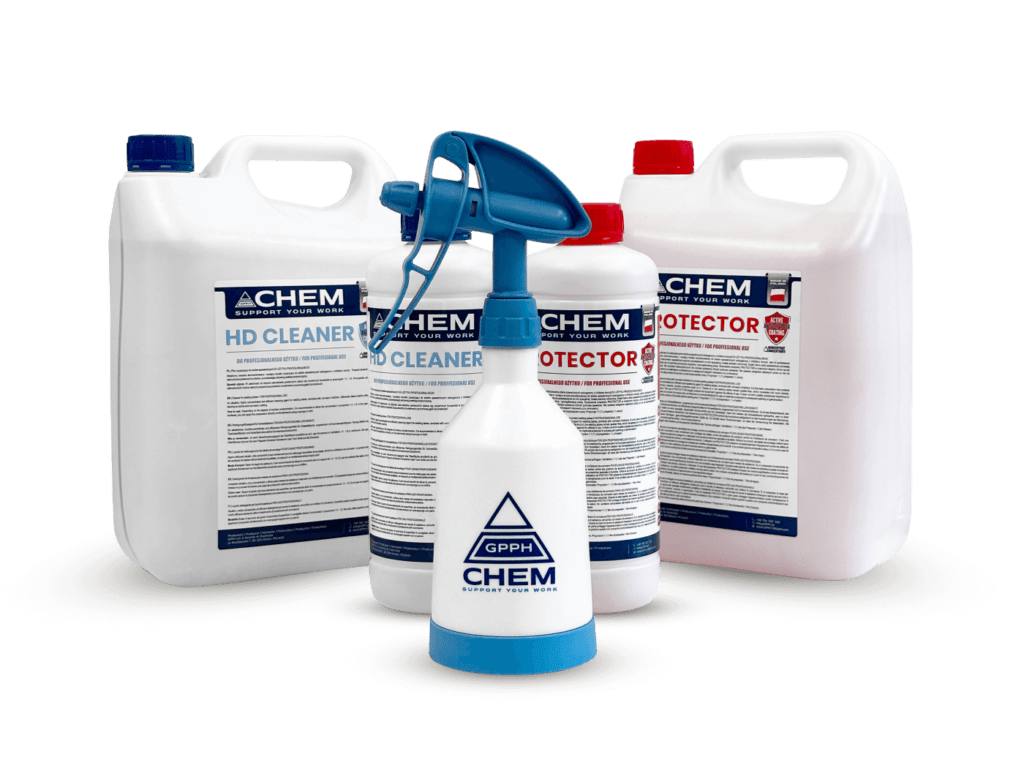

Take care of the longevity of your grinding and welding station. Use GPPH CHEM's professional chemicals for proper care and protection to keep it always in top shape.

Protector is an anti-scratch concentrate that will create a long-lasting protective layer, effectively protecting against welding spatter and corrosion. HD Cleaner, on the other hand, a highly concentrated cleaning fluid, perfectly removes heavy dirt, leaving the table surface in impeccable condition.

Thanks to GPPH CHEM's professional products, your grinding and welding station will be in excellent condition, contributing to greater working efficiency and long-lasting use of this reliable equipment. Provide your stand with proper care and enjoy its durability and high quality for many years!

GPPH S.C. © 2025 All rights reserved.

Podaj swój adres e-mail, aby zachować zawartość koszyka i wrócić do zakupów w dogodnym momencie.