Menu

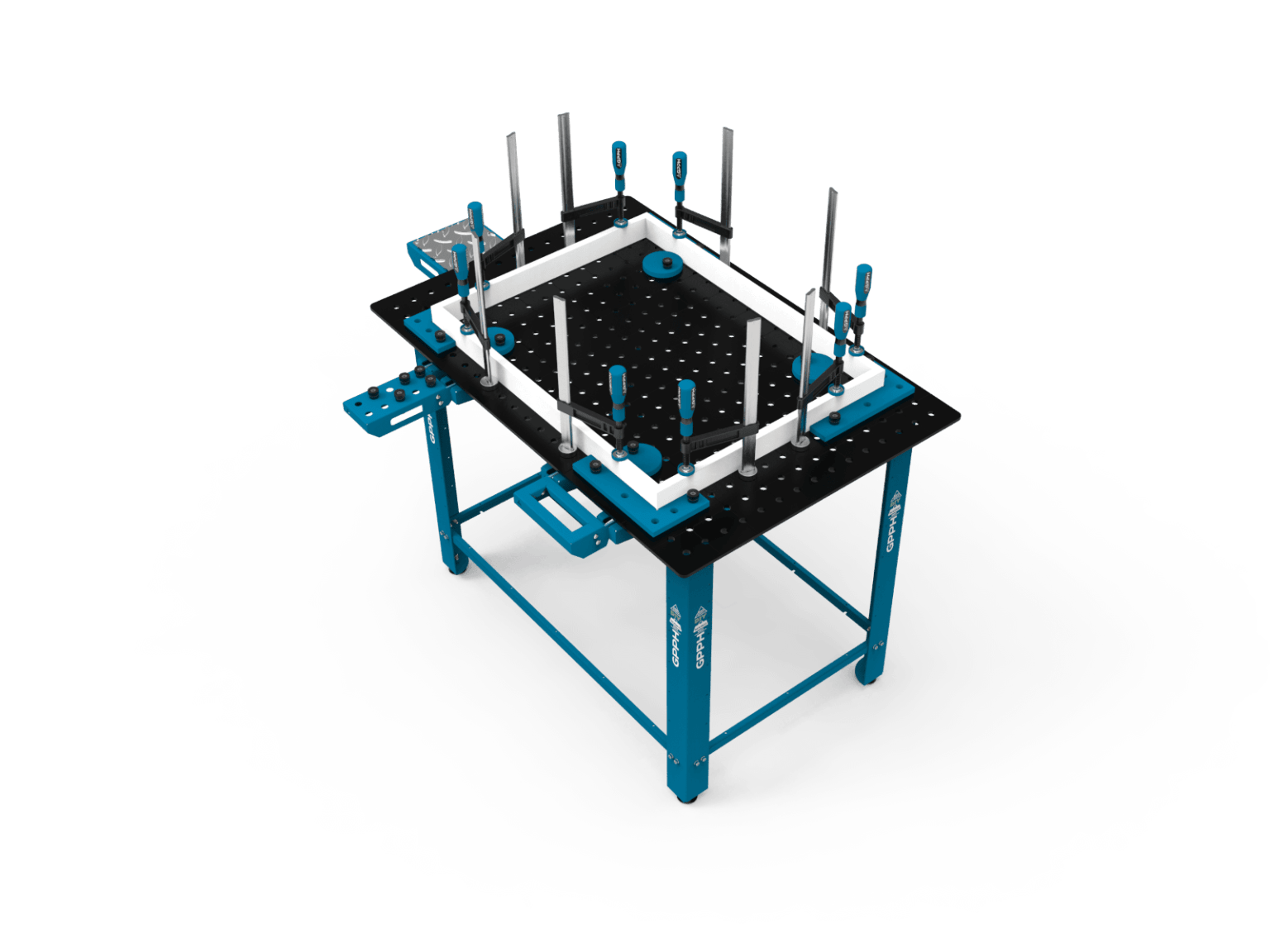

Are you looking for a versatile welding table that meets the requirements of professionals and DIY enthusiasts alike? The DIY welding and assembly table is the answer to your needs! The exceptional quality and versatility of this product will make it an invaluable tool in a variety of industries and workshops.

The DIY welding and assembly table top, measuring 1200x800 and with a load capacity of 500 kg mm, is the ideal work surface for a wide variety of jobs. Its thickness of 8 mm provides durability and strength, guaranteeing stability during welding, assembly and other tasks. In addition, the ⌀16 mounting holes in the 50x50 mm grid and the engraved graduation in the 100x100 mm grid allow precise and easy fixing of tools and components.

The legs of the DIY table are equipped with pendulum feet that level out uneven floors. This ensures that, even on uneven ground, the table is stable. A set of wheels is also available for this table series. The welded ribs reinforcing the structure further increase the strength and durability of the table, ensuring long-lasting use.

The DIY welding and assembly table series is a versatile tool that is perfect for a variety of trades and workshops. Whether you are a welder, DIYer, carpenter or auto mechanic, this table will be an indispensable assistant during your work. It can be used as an auxiliary table for CNC machines or as a versatile surface for various tasks and projects.

Bet on the quality, functionality and versatility of the DIY series of welding and assembly tables. It's a tool that will help you achieve excellent results in your work, ensuring stability, precision and comfort. Whatever the requirements of your workshop or production, this table will meet all challenges. Choose the DIY series and discover the full potential of this reliable tool!

DIY welding and assembly tables are versatile tools that excel in a variety of applications. Here are a few of them:

All these applications make DIY welding and assembly tables an invaluable tool for many industries, providing convenience, precision and efficiency.

DIY welding and assembly tables are characterised by their build quality, versatility and practicality. These compact 1200x800 mm tables offer many advantages. The stable construction of the table frame guarantees durability and reliability.

The table top, with a thickness of 8 mm, is made of S355J2+N material, meeting the ISO 2768-1 standard, which ensures high quality and precision. The ⌀16 mounting holes in the 50x50 mm grid and the engraved graduation in the 100x100 mm grid facilitate precise placement of tools and components.

In addition, it is equipped with swing feet that allow:

... for levelling uneven floors, and the height adjustment of the feet allows the table to be adapted to the user's individual preferences. We also offer a set of wheels that can be fitted instead of feet - making the DIY table more mobile. The welded reinforcing ribs provide structural strength and the static load capacity reaches 500 kg, making it ideal for many applications.

The DIY welding and assembly tables are compatible with tools from the PLUS series, mounted with the ECO/PLUS shank in the ⌀16mm system. These features make the DIY tables a versatile tool in a variety of industries, ideal for professionals and DIY enthusiasts alike. By choosing DIY welding and assembly tables, you are investing in the productivity, quality and durability of your work.

DIY welding and assembly tables are reliable equipment that can cope with even the most demanding tasks. Thanks to their versatile technical features and high quality workmanship, they

provide comfort and efficiency for professional welders, DIYers, carpenters, mechanics and many other trades.

Choose DIY tables and experience reliability and comfort in your work!

The DIY welding and assembly table is a robust and versatile piece of workplace equipment that provides the highest quality workmanship and customisation to suit your needs. The main technical parameters of the DIY table are:

Although the DIY welding and assembly tables have a work surface of 1200x800 mm, it is this compact size that brings many advantages and benefits to users.

The smaller working area of DIY welding and assembly tables does not mean a limitation of possibilities, but on the contrary, it allows flexibility and efficiency in many jobs. These tables are worth appreciating for their practicality, comfort of use and ability to be used even in limited spaces.

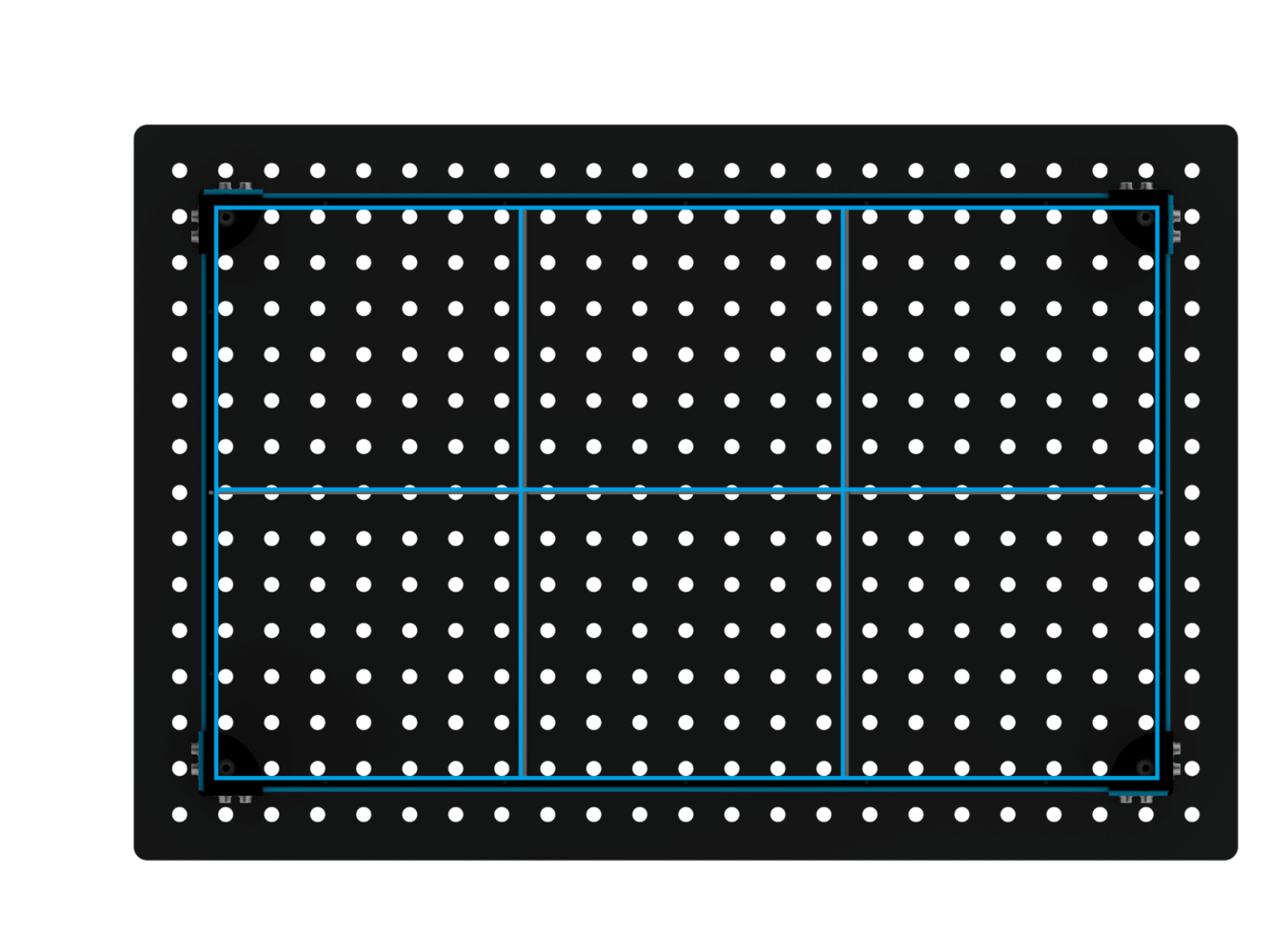

The system and hole grid of the DIY welding and assembly table have been designed for maximum versatility and practicality. The ⌀16 mm diameter mounting holes, arranged in a 50x50 mm grid, offer many advantages and open up a wide range of application possibilities.

Thanks to this design, the user has the freedom to mount a variety of tools, fixtures or workpieces in multiple configurations. Laser-fired holes guarantee precision and repeatability of dimensions, which translates into easy and quick assembly and accurate positioning of components.

The 50x50 mm hole grid allows flexible positioning of workpieces on the table, which is particularly beneficial for welding, assembly or other workshop work. Thanks to its adjustable positioning, the DIY tables adapt to the individual user's needs, increasing productivity and efficiency.

This versatile hole grid makes the DIY welding and assembly tables the ideal tool for a wide range of industries, including manufacturing, welding, metalworking, and wherever precision and stability are required when assembling and working on a variety of components. With a ⌀16 in 50x50 mm grid, the DIY welding and assembly tables are an efficient, functional and reliable tool in your workshop, guaranteeing professional results in every application.

The ribs of the DIY welding and assembly table provide a solid base for the tabletop, which has a positive effect on productivity and quality of work. Thanks to the specially designed welded ribs, the table gains additional strength and stability. This is a key element for carrying out precise and demanding welding and assembly tasks.

The benefits of a ribbed DIY table are numerous. Firstly, it ensures that loads are evenly distributed so that the welding table does not deform. This robust design allows you to focus on welding and assembly tasks without worrying about the tabletop becoming unstable.

The ribbing also increases the lifespan of the table, as it reduces the risk of cracks or deformation on the tabletop surface. This is a key factor in ensuring the table's long-lasting and reliable operation for many years.

The legs of the DIY welding and assembly table are equipped with special pendulum feet that perfectly level out floor irregularities.

As an additional option, a set of wheels can be purchased for the DIY table. With this solution, the welding table becomes mobile, making it possible easy to move it around in the workshop or production hall.

A set of wheels adds mobility and flexibility to the table, which is extremely practical, especially in factories, workshops or other places where the DIY welding table may be used.

Swivelling feet and the option to mount wheels are important advantages of DIY welding and assembly tables that contribute to their functionality and versatility. Thanks to them, the user is able to adapt the table to his or her needs and ensure comfortable working regardless of the environment.

In our range you will find DIY welding and assembly table accessories that will significantly speed up and facilitate your work.

The DIY welding and assembly table wheel set is a practical accessory that gives you the freedom to move the table around the workshop. The mobility provides convenience and efficiency during welding and assembly work. The wheels are robust and durable, ensuring smooth movement of the table even under heavier loads.

In addition, the wheels are equipped with an extendable footrest, so that when the table is transported to a given location and the footrests are extended, the table does not move.

Adapters for tool shelves are another versatile accessory that greatly enhance the functionality of a DIY welding and assembly table. Once fitted, mobile tool shelves can be easily attached directly to the table, allowing tools and accessories to be stored within easy reach. This is particularly important in workshop environments where organisation and easy access to tools are key to efficient working.

The advantages of these solutions are numerous. A set of wheels that provides mobility for the table allows flexible workstation adaptation, which can increase productivity and efficiency in welding and assembly work. By being able to move the table to different locations in the workshop, time and effort can be saved by avoiding the need to carry heavy objects.

Adapters fot tool shelves, on the other hand, make organising tools and accessories much easier. They allow table space to be used more efficiently, which increases tidiness and makes work easier. Attaching shelves to the table also keeps tools and accessories in order, which can make a significant difference to productivity and precision.

With these accessories, DIY welding and assembly tables become even more functional and practical, adapting to the user's diverse needs. It's an investment that makes everyday work much easier, providing convenience and organisation, which in turn translates into better results and satisfaction from work done efficiently.

Trzpienie mocujące szybkiego montażu ECO/PLUS 19-22 w systemie ⌀16mm stanowią idealne rozwiązanie dedykowane do stołów spawalniczo-montażowych DIY. Ich wyjątkowe cechy i zalety sprawiają, że są niezastąpione w procesie montażu i spawania.

Główną zaletą tych trzpieni jest łatwość i szybkość montażu. Można je łatwo i sprawnie zamontować w otworach stołu z narzędziami, co pozwala na błyskawiczne przygotowanie stanowiska spawalniczego. To szczególnie istotne w przypadku częstych zmian narzędzi i szybkich przejść między różnymi projektami.

Trzpienie ECO/PLUS 19-22 w systemie ⌀16mm zapewniają stabilność i pewność mocowania narzędzi. Ich precyzyjne wykonanie gwarantuje sztywność i dokładne pozycjonowanie narzędzi, co przełoży się na doskonałą jakość spawania i obróbki.

Korzyści płynące z używania tych trzpieni są nieocenione dla każdego profesjonalnego spawacza. Eliminują ryzyko przesunięć i luźnego mocowania, co pozwala skupić się na pracy bez obaw o jakość i precyzję. Dzięki nim, montaż i spawanie stają się bardziej efektywne, a cały proces przebiega szybciej i sprawniej.

A set of milled tools is the key to achieving precise and efficient designs on DIY welding and assembly tables. For this version of the table, you will use the tools from the PLUS series, mounted with the adjustable ECO/PLUS fast assembly bolts. Try them out and see the difference!

Make repetitive flat and spatial constructions conveniently with our milled welding and assembly table tools. Check out our suggestions for ready-to-use DIY table tool sets and make your work more efficient.

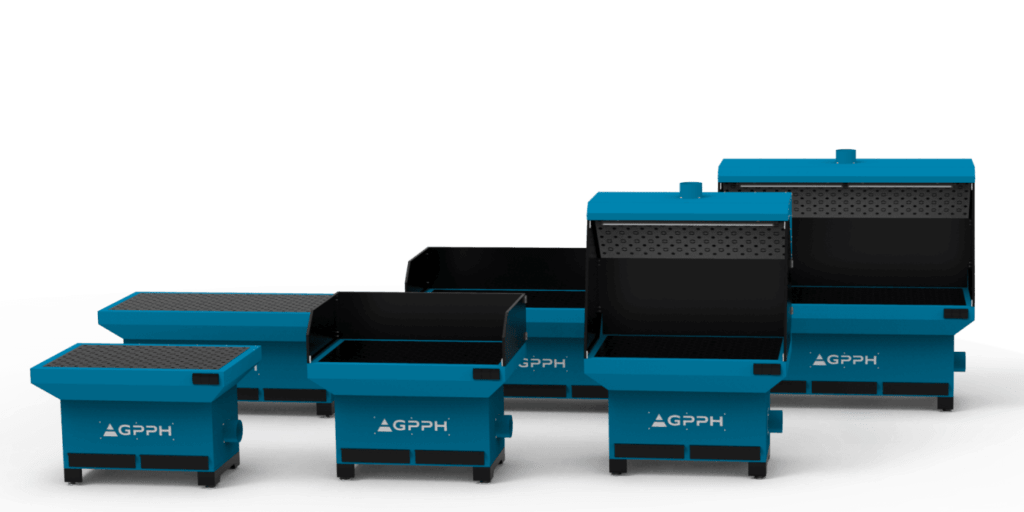

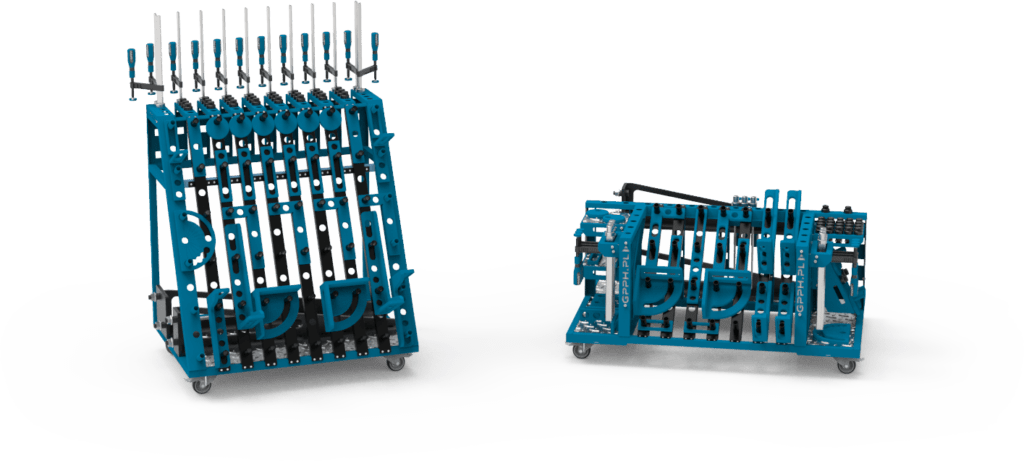

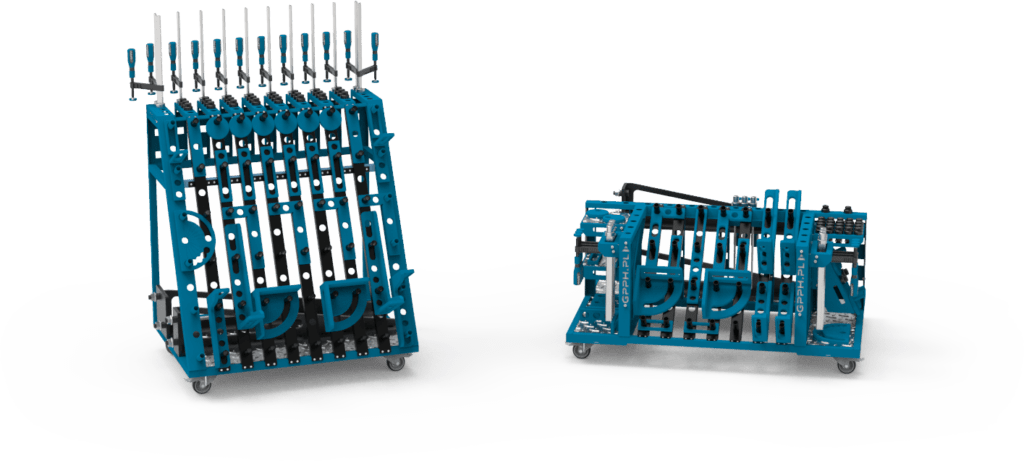

Start your adventure into perfect organisation with our tool trolleys! They are the key to keeping your workstation tidy.

Forget about the clutter! Our small tool trolley will hold all your tools so that you can concentrate on effective work.

The large tool trolley is your solution for organising your full tool kit. Be ready to tackle even the most demanding tasks.

GPPH tool trolleys are your support to stay organised and focused on productivity. Choose quality and feel the difference in your work!

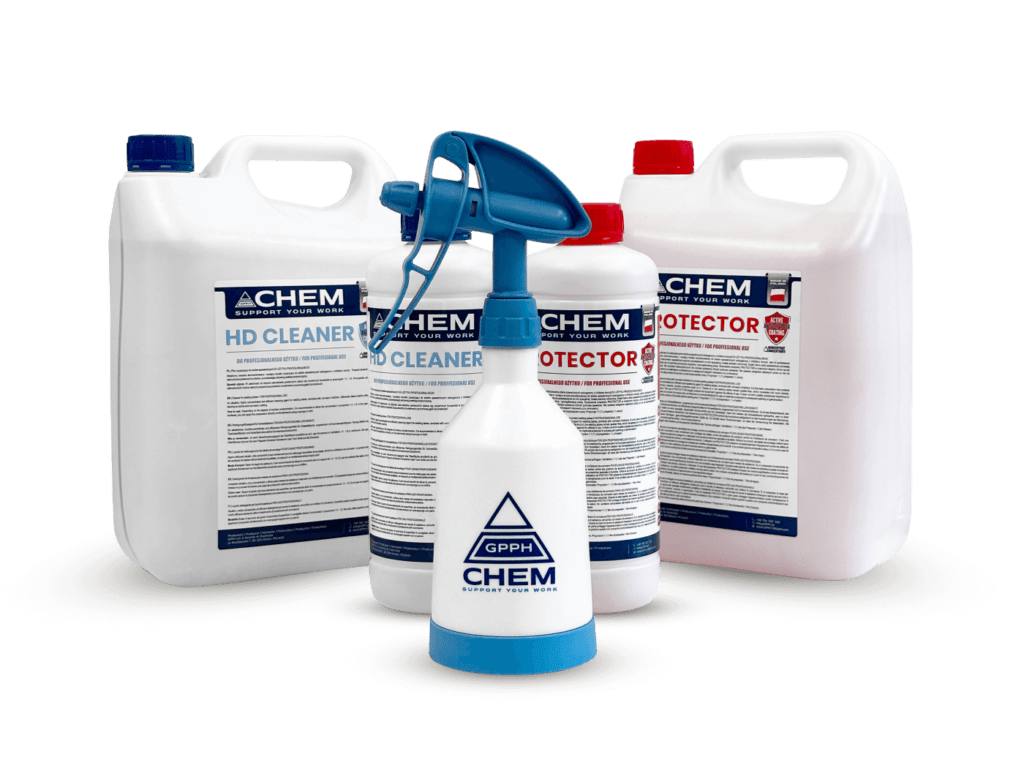

Don't forget to take care of your welding table! GPPH CHEM offers special products such as Protector and HD Cleaner to take care of its durability and impeccable condition.

Protector is an anti-scratch concentrate that forms a durable and protective film to protect against welding spatter and corrosion. HD Cleaner, on the other hand, is a highly concentrated cleaning fluid that effectively removes tough dirt.

GPPH CHEM professional products will ensure proper care of your welding table, which will translate into longevity and precision. Take care of your equipment and enjoy maximum performance during every weld.

| Copyright GPPH S.C. © 2024 |

Achieve perfect organisation with our small tool trolley that allows you to have all your tools within easy reach.

Need even more capacity? Our large tool trolley will accommodate even the most extensive tool sets. Everything will be organised and ready to use.

Work efficiently and precisely when creating flat and spatial structures with our tools and accessories for welding tables.

Choose ready-made tool sets or compose your own set and gain an improvement in your daily work.

Welding table care is the key to its long life. Choose GPPH CHEM professional chemicals and enjoy effective work for many years.

Achieve perfect organisation with our small tool trolley that allows you to have all your tools within easy reach.

Achieve perfect organisation with our small tool trolley that allows you to have all your tools within easy reach.

Need even more capacity? Our large tool trolley will accommodate even the most extensive tool sets. Everything will be organised and ready to use.

Our innovative grinding and welding stations effectively eliminate dust and gases generated during grinding and welding work. They work together with an extractor or filter fan, effectively improving the air quality around the workstation.

They will help you achieve greater efficiency in your work, focusing on excellent results.