Limited floor space is one of the biggest challenges in welding workshops. Lack of space quickly affects ergonomics, working time and safety. Fortunately, a well-planned workstation allows you to make the most of even a small area. Below we present three sets of tricks that truly change the way you work.

1. One square meter that works for three

Trick 1: The table does not stand still - the table works

In a small workshop, a welding table cannot be just a piece of furniture. It must be a mobile command center. Tables on wheels allow you to move the workstation to the center when welding a large structure and “push it aside” when working on smaller parts. It is a simple way to regain space without renovation.

Trick 2: What is under the table is not on the floor

If the space under your table is empty - you are wasting space. A lower shelf is the perfect spot for a welding machine, a vise or profiles that are constantly in use anyway. Under most tables, the GPPH M tool trolley will also fit easily, so everything you need is literally within reach. This way, the floor stops being a storage area and the workshop automatically becomes “larger”.

Trick 3: A smaller tabletop ≠ fewer possibilities

It is better to have a smaller table with perfect flatness and a system of milled holes than a large plate made of random sheet metal that “has a life of its own”. A stable tabletop and repeatable clamping points let you use every working centimeter - without improvisation and without fighting the table.

2. Versatility instead of five separate workstations

Trick 4: You change the tools – not the table

In many workshops, separate workstations are created simply because “this one is for one task and that one is for another”. Meanwhile, with one table it is enough to change the clamping tools and the workstation gains a completely different function. A frame, a detail, a spatial element – everything is done in the same place, just with different equipment. This eliminates the need for separate stations “for specific jobs”.

Trick 5: Modules instead of permanent expansion

Long elements? Large dimensions? Instead of buying a huge table, it is better to reach for TRESLE welding supports or extensions. For the duration of the project, you increase the working surface, and once the job is finished, you return to a compact layout.

Trick 6: Drawers are a turbo boost for efficiency

A set of drawers under the tabletop is not a luxury - it shortens every operation by a few seconds. Tools are always in the same place, no walking around, no searching. In a small workshop, it is the difference between smooth work and constant mess.

3. Ergonomics and OHS - because in a small space it gets “stuffy” faster

Trick 7: The things you put down every minute need their own place

In a small workshop, the biggest mess is not made by large parts, but by small items put down “for a moment”: the torch, documentation, small tools. When they have no dedicated place, they end up on the tabletop or anywhere within reach. A torch holder, a mobile tool shelf or a dedicated spot for documentation helps organize the workstation without adding more equipment. The result? A clean tabletop, better ergonomics and fewer nervous movements during work.

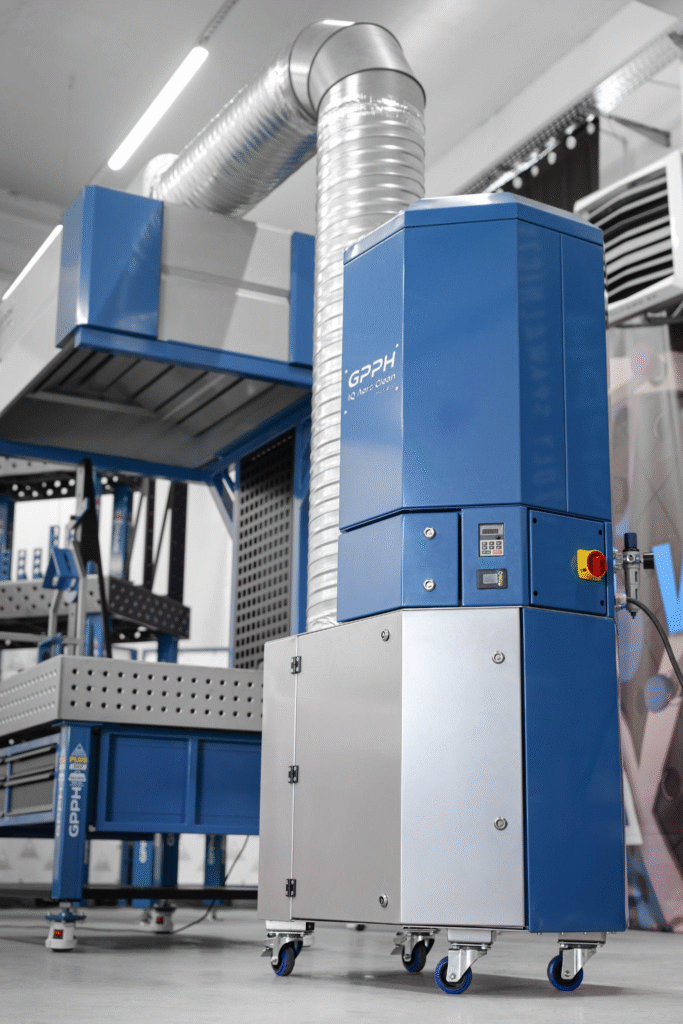

Trick 8: Smoke has nowhere to escape - so you need to remove it

In a small workshop, welding smoke and fumes build up extremely fast, reducing both comfort and safety. That is why fume extraction and filtration systems are crucial - working exactly where contaminants are generated. Solutions such as IQ Air Flow - a welding hood mounted above the table - or IQ AeroClean effectively remove welding smoke without taking up valuable workspace. This is a real improvement in working conditions where every meter matters.

Trick 9: Less reaching and twisting = less fatigue

In a small workshop, your body feels the effects of poor workstation organization faster. Constant reaching over the tabletop, twisting your torso, or working “sideways” to the table leads to fatigue and reduced concentration. When the workstation is designed so that most tasks are done in a natural position - facing the table and within arm’s reach - work becomes smoother and safer, even in a limited space.

A small workshop does not have to mean compromises. A properly planned space, a well-chosen workstation and thoughtfully selected accessories ensure that even a limited area can operate efficiently, safely and ergonomically. It is details such as mobility, modularity and good workstation organization that determine whether work flows smoothly or requires constant workarounds and improvisation.

At GPPH, we design solutions that allow you to get the most out of every meter of your workshop - because we know that it is not the size of the hall that matters, but how you use it.