At a time when technological innovation is transforming the welding industry, welding chemistry is becoming an indispensable part of the welding process, affecting key aspects such as productivity, quality and safety. In response to these growing needs, developments in the welding chemicals industry include a range of products and solutions that make welding work easier and more enjoyable. Knowing how to use the right welding chemicals is crucial to achieving optimum weld quality, process efficiency and ensuring workplace safety. It is therefore important for welders and those responsible for managing the welding process to know the importance and proper use of welding chemicals.

Which welding chemicals to choose?

Professional welding chemistry can be purchased by contacting GPPH, which in addition to welding tables offers HD Cleaner, Protector anti-scratch product, as well as a specially dedicated sprayer to help evenly distribute the products on the welding table surface. Check out the professional welding chemicals on the GPPH manufacturer's website.

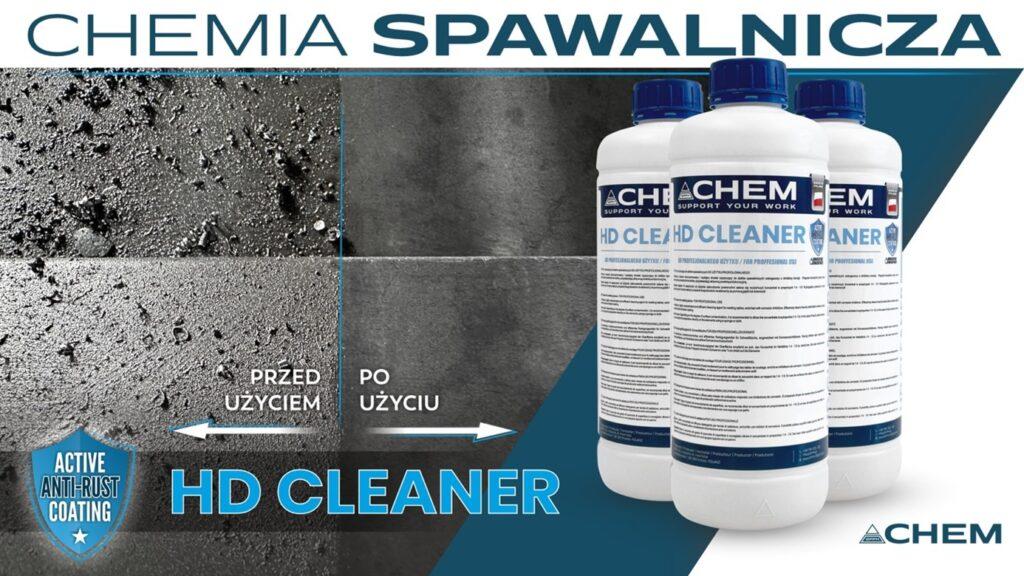

HD Cleaner, is a powerful and effective welding table cleaner that is alkaline, highly concentrated and very efficient. The formulation contains corrosion inhibitors so that it not only removes heavy dirt but also leaves an active anti-corrosion coating on the table surface. Thanks to its special formulation, HD Cleaner provides high cleaning efficiency, making it ideal for those looking for an effective and easy way to keep their welding table clean.

Protector, is a highly concentrated anti-scratch agent that has been enriched with corrosion inhibitors. It is an indispensable formulation for the protection of welding benches, as it leaves a durable protective layer on them, which protects against splatter and the effects of use. As a result, welding tables remain clean and do not require frequent maintenance. The formulation is odourless and can be used safely in all conditions.

The HD Cleaner and Protector formulations are water-based. Both are easy to apply and do not emit hazardous volatile substances during welding. In addition, they are free of oil compounds and silicones, making them suitable for use on materials subjected to subsequent stages such as painting or galvanising.

Professional welding chemicals play a key role in welding and metalworking processes, ensuring quality, productivity and safe workmanship. The use of the right products in each step of the welding process is fundamental to achieving optimal results. Thanks to technological innovation and the continuous development of welding chemistry, the industry is able to meet the growing demands of different industries and adapt to the needs of today's market. For professionals and amateurs alike, the use of GPPH's welding chemistry is key to achieving satisfactory work results, minimising the risk of errors and ensuring the long-term durability of welded materials.