In many workshops, a welding table is treated solely as a work surface. In modern production processes, however, it is a system component that has a direct impact on lead time, repeatability of structures, and the welder’s working comfort. An improperly set up or poorly selected table not only slows down work, but very often generates errors that only become apparent during assembly or quality control.

Based on conversations with users and experience from welding workstation implementations, five mistakes can be identified that occur most frequently.

1. Lack of proper table leveling - or no table at all

The first and most fundamental mistake is the lack of proper table leveling. Even small deviations are critical for longer structures, frames, or spatial elements. If the table does not provide a perfectly flat reference base, the entire structure begins to drift, and the welder loses time constantly correcting the position of components.

In practice, an even worse situation is also encountered – welding without a table, directly on the floor or on makeshift supports. Such work completely eliminates a reference point, prevents precise positioning of components, and significantly increases the risk of geometric errors. This approach may only work for the simplest tasks, but in serial or structural production it leads to losses in time and quality.

GPPH welding tables are designed to maintain a very high flatness tolerance across the entire tabletop surface. However, full use of this precision is only possible when the table is properly leveled and set on a stable base. That is why adjustable feet and a robust leg structure are such essential elements of the entire system.

It is worth noting that for most GPPH table series, the flatness tolerance is ≤ 0.3 mm across the entire tabletop surface. For the SMART series, as an economical alternative, this tolerance is ≤ 0.5 mm, which still provides a stable and predictable base for most welding tasks.

2. Improper use of the hole system and lack of reference to axes

The second common problem is the improper use of the hole system. Many users have tables with a dense hole grid but do not use it in a deliberate way. Components are positioned “by eye”, without reference to axes, scales, or base points, which results in a lack of repeatability and the need to “set everything up again” each time.

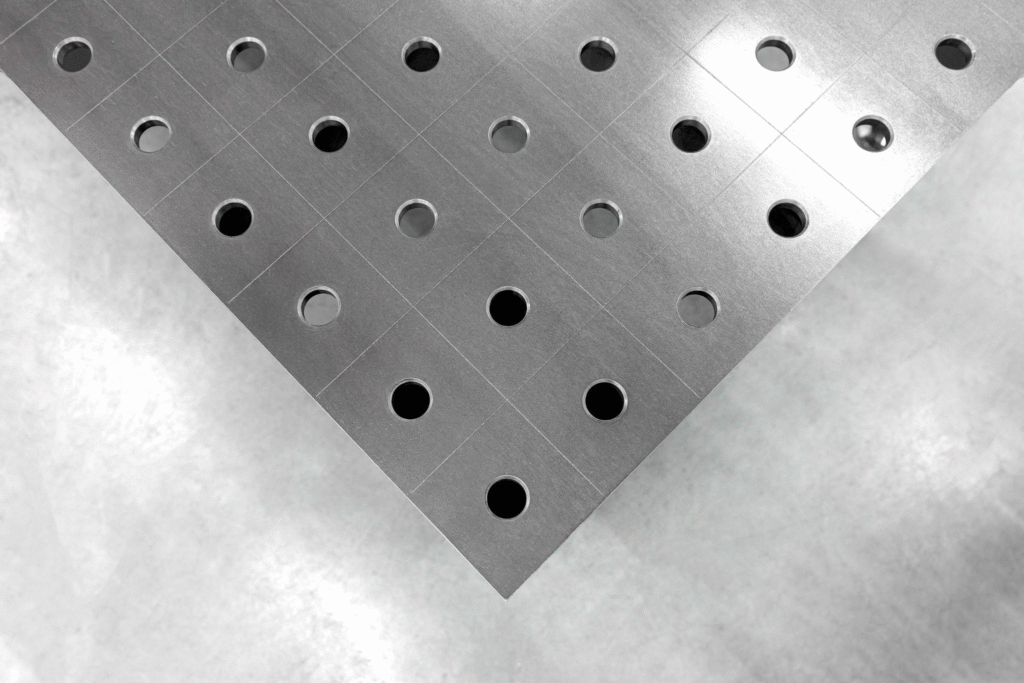

The hole systems used in GPPH tables – both in the 100x100, 50x50 grid and in the diagonal layout – are designed to reduce positioning time and enable fast, repeatable setup of structures. The engraved scale on the tabletop further facilitates work and allows the table to be treated as a precise measuring tool rather than just a work surface.

Milled and chamfered holes also play an important role here. They ensure precise seating of pins and tools, eliminate play, and facilitate quick assembly and disassembly of clamping elements. These are details that, in everyday work, genuinely reduce workstation setup time.

3. Too few clamping points for the workpiece

In many workshops, parts are clamped using “whatever is at hand”, often with the minimum number of points. During welding, however, the material heats up, moves, and generates stresses which, without proper force distribution, cause components to shift already during welding.

GPPH tools – including clamps, pins, and positioning elements – are designed for specific hole diameters and table series. As a result, they form a coherent system that allows precise positioning of the workpiece and maintains its position throughout the entire welding process. Instead of improvisation, control comes into play: proper distribution of clamping points, repeatable positioning, and structural stability. This directly translates into higher build quality, reduced deformation, and real time savings at every stage of production.

4. Failure to treat the table as a base for workstation expansion

The fourth mistake is treating the welding table as a one-time solution rather than as a working base. In practice, this often means that the table functions as an isolated element of the workstation – without the possibility of expansion, connection with other tables, or the use of additional components supporting the welding process. With larger or more complex structures, the limitations of this approach quickly become apparent. The lack of welding supports, blocks, extensions, or connection systems forces projects to be divided into stages or carried out in uncomfortable positions. This extends lead times and increases the risk of geometric errors and loss of repeatability.

GPPH welding tables are designed as system components. They can work together with TRESTLE welding supports, connectors, modular tables, and SLIDE SYSTEM rail systems. This allows the workstation to be flexibly adapted to the current project – instead of forcing the project to fit the limitations of the table. Such an approach streamlines the process, shortens working time, and increases production flexibility.

5. Disorganized workstation

The fifth mistake is the lack of real workstation organization. When tools have no designated place, clamps end up on the tabletop, and the welder constantly interrupts work to look for something, the process loses its flow. Each such interruption means lost time, but also a loss of work rhythm and concentration, which in welding directly affects the quality of execution.

A well-designed workstation eliminates these problems at their source. System drawers, lower shelves, or complete welding stations allow the table to be integrated with tools and accessories instead of placing them “anywhere.” When everything has its place and is within reach, the welder can focus on the job rather than organizing the workspace during the process.

Avoiding these five mistakes does not require a revolution, but a change in approach. The key is to treat the welding table not as a random work surface, but as the foundation of the entire process. Stable leveling, conscious use of the hole system, appropriate clamping tools, the possibility of workstation expansion, and organized workflow together create a coherent welding solution. This is exactly how GPPH solutions are designed – so that the welding table becomes real production support, not a source of limitations. It is the simplest path to faster work, greater repeatability, and higher construction quality.