A welding table is an indispensable tool for any DIYer who wants to improve their welding skills. It provides a stable and safe work surface, which is crucial for precise and high-quality welding work. However, with the variety of welding tables available on the market, choosing the right one can be a difficult task. In this guide, you'll find information about the different types of welding tables, their advantages and disadvantages, and useful tips that can help you choose the right one.

There are several types of welding tables that are suitable for different applications and budgets. Here are the most common ones:

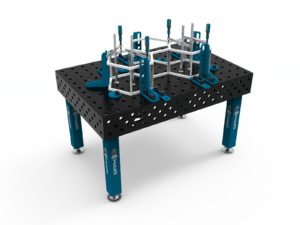

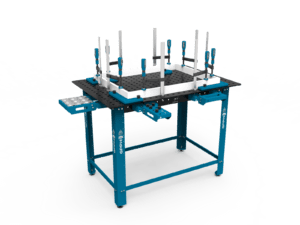

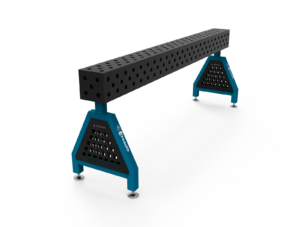

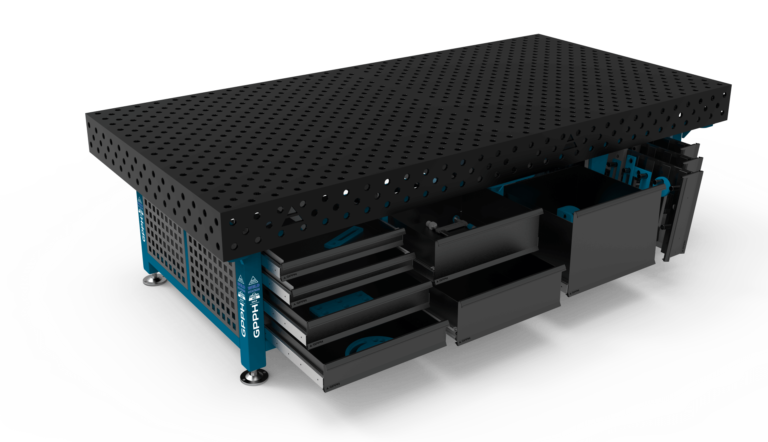

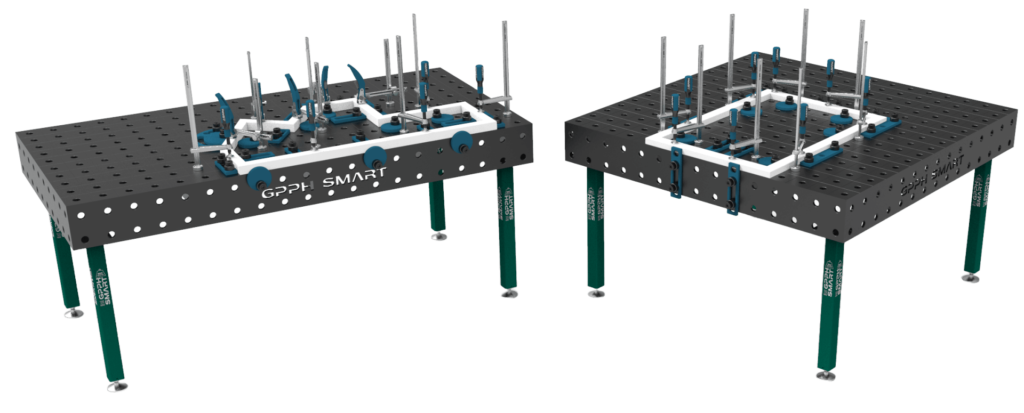

- Traditional welding tables: the most popular on the welding market. Robust and durable welding tables that offer a high load capacity. They are ideal for heavy welding work. They provide comfortable and efficient working conditions while guaranteeing high precision and repeatability when carrying out constructions.

Advantages:- Very stable and durable

- High load capacity

- Heat resistant

- They come in different series of tops

- Large selection of sizes

- Stainless steel welding tables: extremely durable with a stable working surface. Made from high quality steel with a high chromium content, they guarantee reliability and eliminate the risk of iron precipitation and corrosion foci. They are ideal for professional welding work where stainless steel projects are welded.

Advantages:- Durable and stable

- High load capacity

- Excellent electrical conductivity

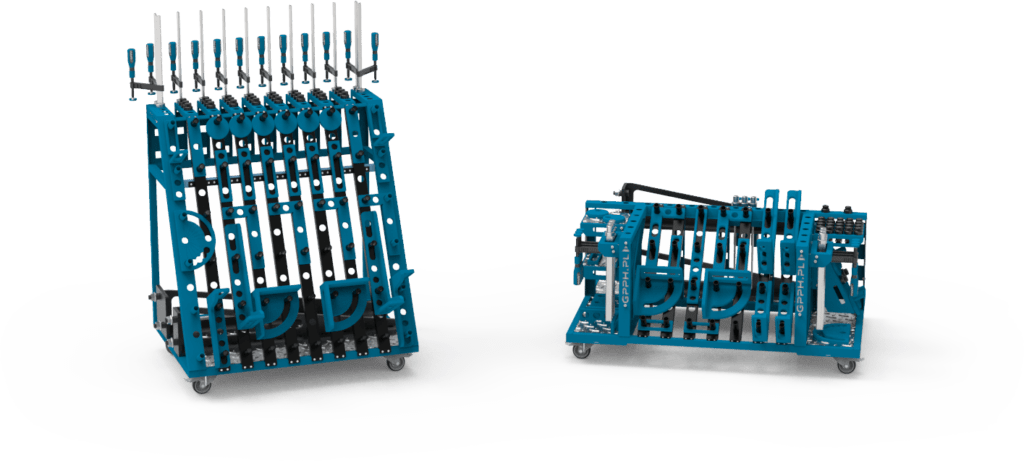

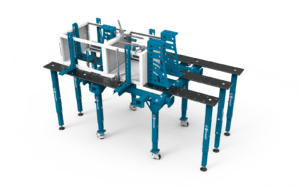

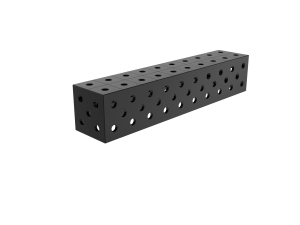

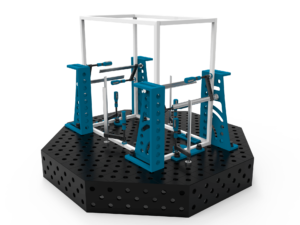

- Welding and assembly tables: versatile that work well in a variety of applications. Ideal not only for manual welding, but also for robotised welding due to the absence of side walls.

Advantages:- They will work well in any workshop

- Affordable

- They are used for manual or robotic welding

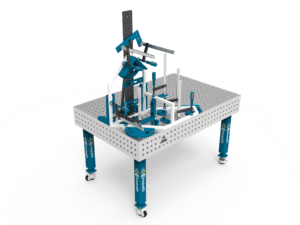

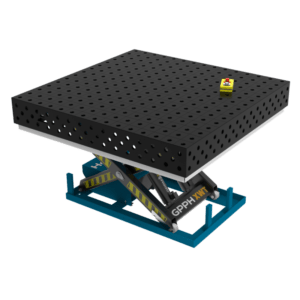

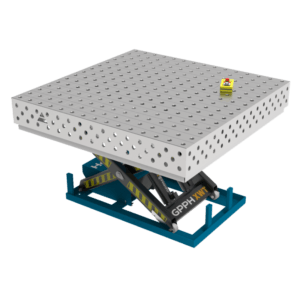

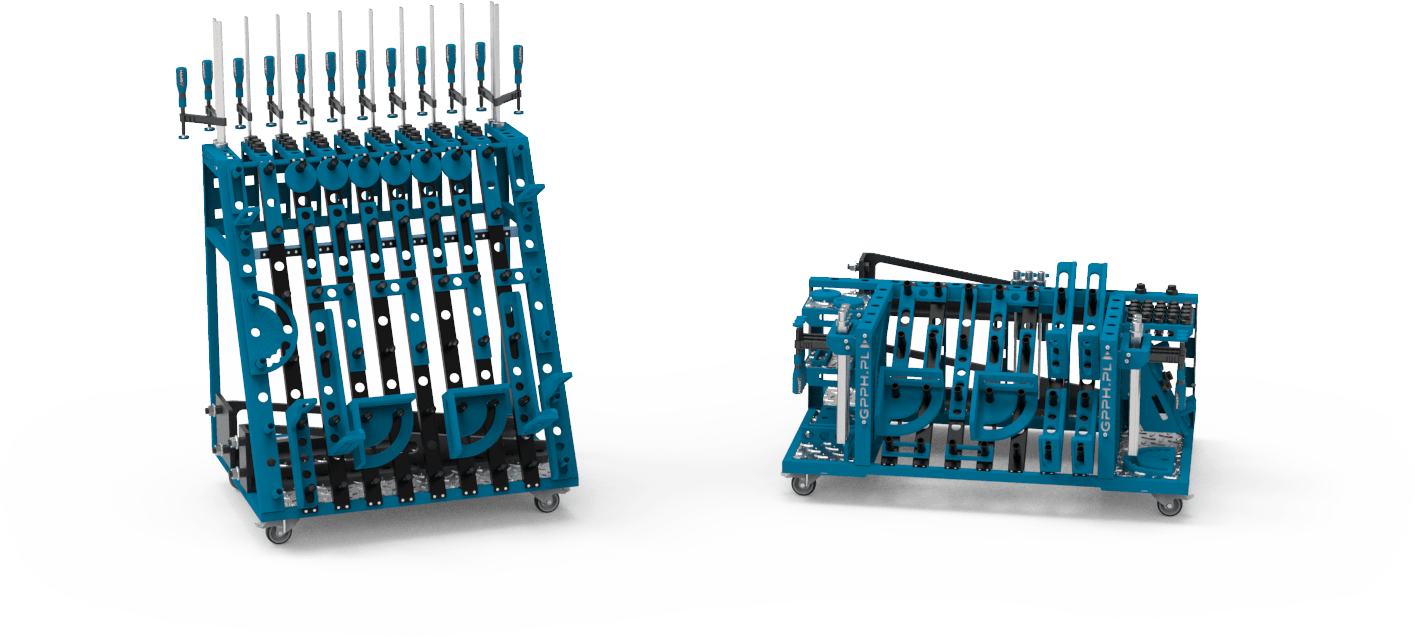

- Lifting welding tables: equipped with a hydraulic lifting system, which makes the work more comfortable and efficient. An excellent choice for professional welders who value comfort, safety and excellent quality of work performed.

Advantages:- Versatile and practical

- Facilitate complex welding work

Choosing the right welding table

When choosing a welding table, there are several factors to consider:

- Type of welding: Think about what type of welding work you will mainly do. For heavy work, you will need a heavy-duty welding table, while for lighter work, a welding and assembly table may suffice.

- Space availability: If you have limited space in your workshop, a small and lightweight welding table may be the best solution.

- Mobility: If you need to move the welding table frequently, a welding table with legs on wheels is ideal.

- Budget: Budget plays an important role in the choice. It is advisable to choose a welding table that meets our individual needs in the workshop and at the same time does not exceed our budget.

- Additional features: Consider whether you need additional features, such as a hydraulic lifting system that can make your work easier.

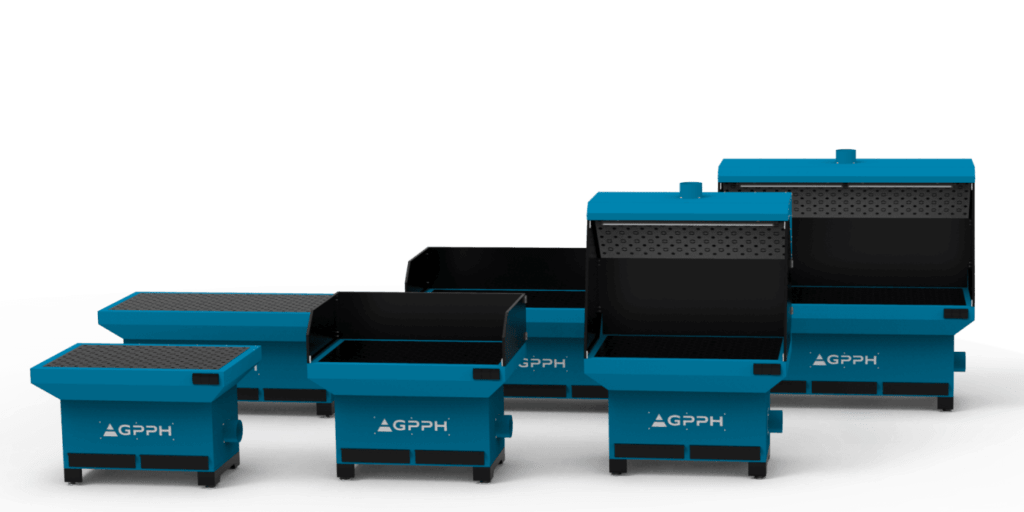

- Quality and manufacturer: Another important factor when choosing a welding table is the quality of the product and the reputation of the manufacturer. It is worth investing in a high-quality welding table from GPPH that will give you reliable service for years to come.

Summary

Choosing the right welding table depends on your individual needs and requirements. When comparing different types of welding tables, focus on their advantages and disadvantages because with these, you will make an informed decision. Also pay attention to the quality and reputation of the manufacturer to make sure you get a durable and reliable product. A quality welding table from GPPH can make welding work much easier and lead to better results.