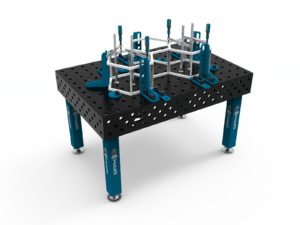

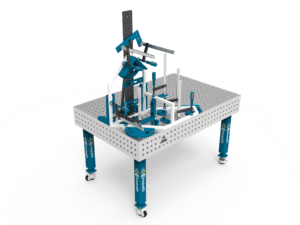

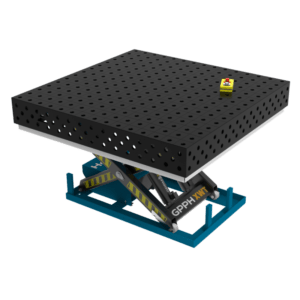

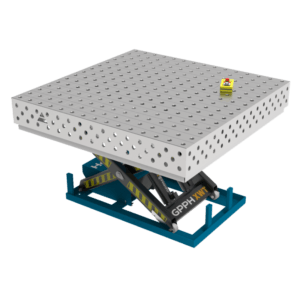

Nowadays, the welding market is looking not only for efficient but also for ergonomic and flexible solutions. To meet these needs, firm GPPH has developed the XWT series of welding tables with hydraulic lifting system, combining innovation with functionality and convenience. Particularly noteworthy is the fact that the XWT series of tables can come in different dimensions and table top thicknesses to meet individual customer requirements.

The innovative solution of the hydraulic lifting system in the XWT series of tables allows the height of the table top to be adjusted as required during work, resulting in better ergonomics and a reduced risk of pain due to an inappropriate welding posture. This system also allows the table to achieve a more precise positioning for the task at hand, leading to more efficient and accurate work.

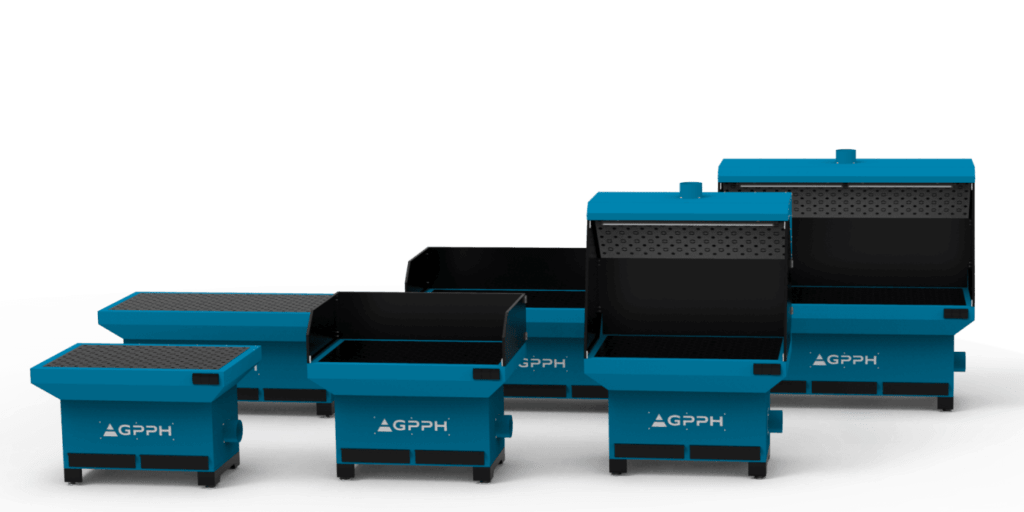

Aware of the diversity of needs in today’s market, GPPH offers XWT series welding tables in 4 size versions: 1500×1000 mm, 1500×1480 mm, 2000×1000 mm and 2400×1200 mm.

In this series of tables we offer table tops in a version:

- PRO, PLUS and ECO – made of S355J2+N steel

- PRO INOX and PLUS INOX – made of stainless steel, grade 1.4301.

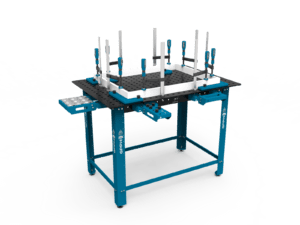

This enables customers to tailor the table exactly to their needs, in order to adapt the product appropriately to their workshop, their work and the type of jobs they are carrying out.

The GPPH XWT series of welding tables with hydraulic lifting system is an innovative and functional solution. Thanks to the flexibility in size and thickness of the table top, by investing in this technology, firms have the possibility to adapt them to their own needs. In addition, the possibility of dofinancing by the Social Insurance Institution means that the purchase can not only be financially advantageous, but can also increase the quality of work and the company’s competitiveness in the market.

Find out how welding tables with a hydraulic lifting system work: