How to extend the life of a welding table?

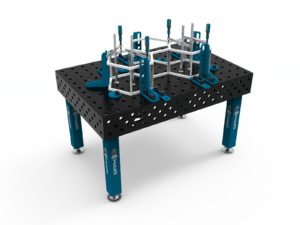

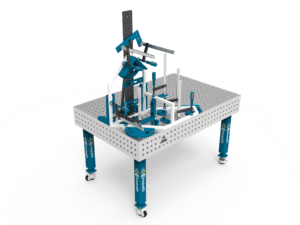

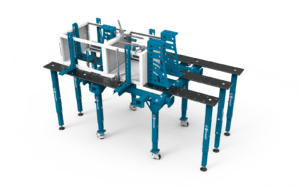

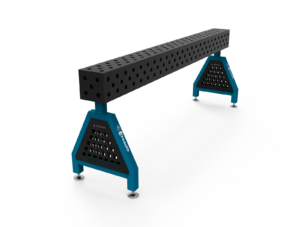

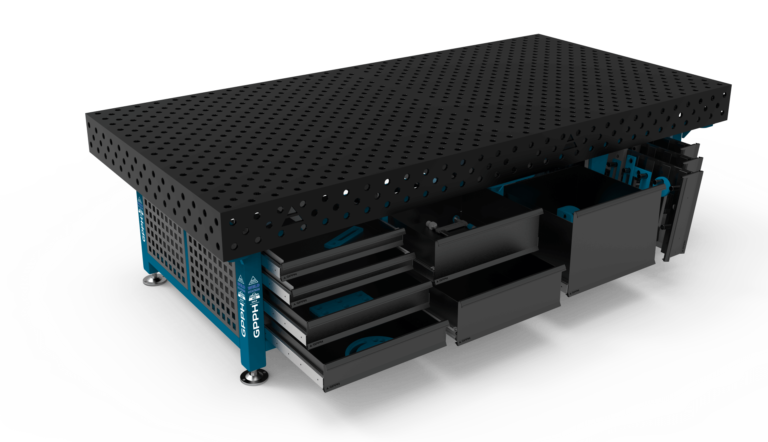

A welding table is an essential investment in any welding workshop. To ensure that your welding table remains in excellent condition for many years, regular maintenance and care is essential. Proper care avoids problems related to corrosion, mechanical damage and loss of performance. This article provides tips on the maintenance and care of welding tables, with a particular focus on GPPH CHEM products - a range of products we have developed to protect and maintain welding tables.

Regular cleaning

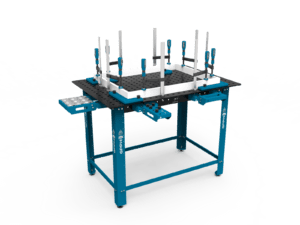

Daily cleaning: Clean the welding table thoroughly after each working day. Remove welding spatter, metal shavings and other residues. Use HD CLEANER to clean the tables.

Weekly thorough cleaning: Perform a more thorough cleaning once a week. Use GPPH Chem products that are specially formulated for cleaning welding tables. These products not only help to keep the table top clean, but also protect it from corrosion and damage caused by welding spatter.

Protection against corrosion

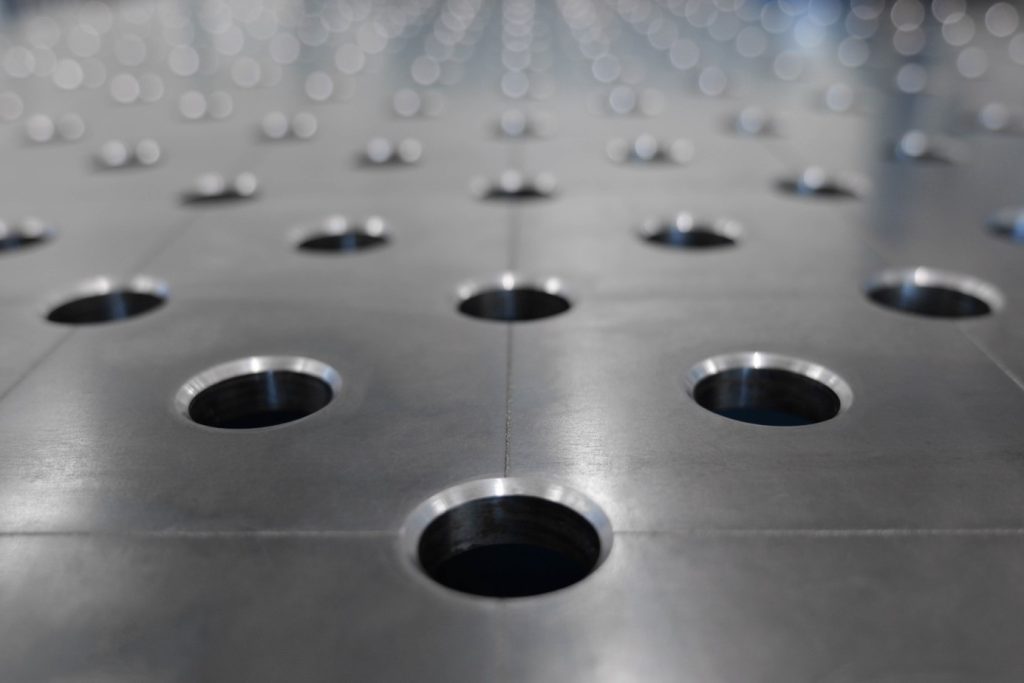

Application of protective measures: Corrosion is one of the biggest enemies of welding tables. Regularly apply an anti-corrosive agent to protect the metal surface. GPPH Chem products should be applied after every job as they provide excellent protection against corrosion.

Storage: Make sure the welding table is stored in a dry place when not in use. Moisture can accelerate corrosion.

Mechanical protection

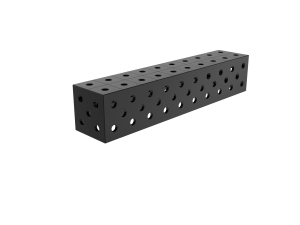

Regular inspection: Regularly check the surface of the welding table for scratches, dents and other damage.

Proper use and maintenance

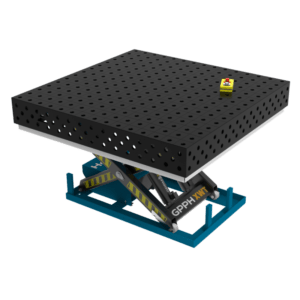

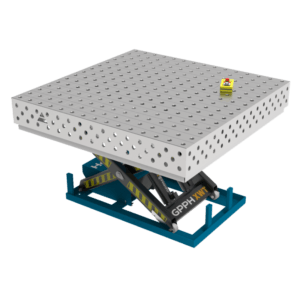

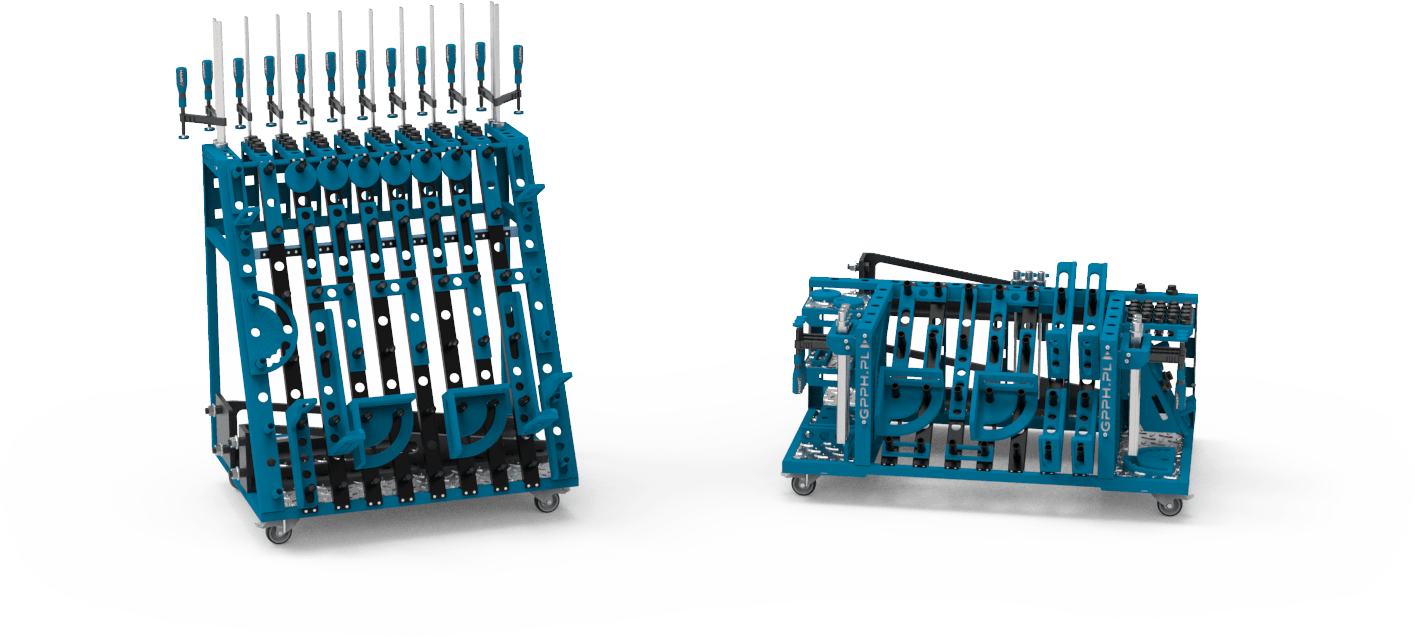

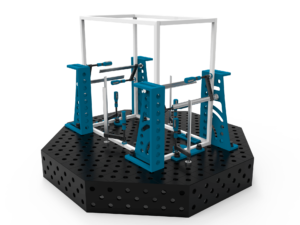

Ergonomic adjustments: Make sure the table is set at an ergonomically comfortable height to avoid unnecessary strain and wear. Correct adjustment helps to extend the life of the table.

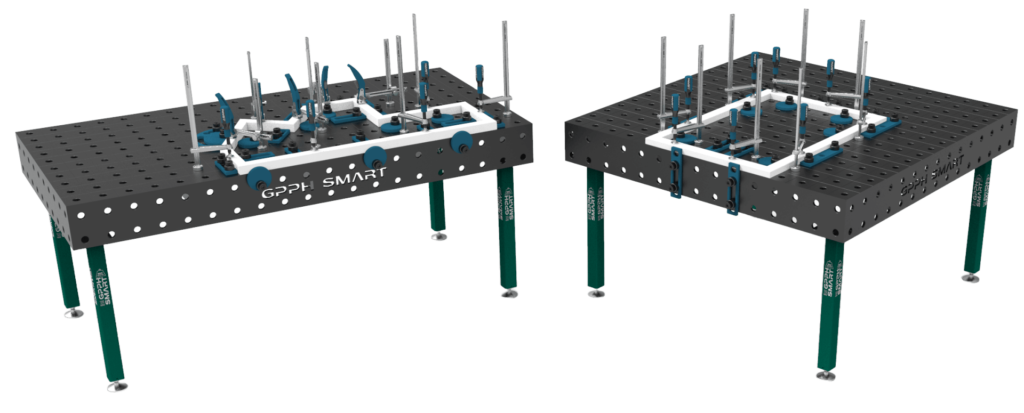

Use the right tools: Always use the right tools to avoid damage to the table surface. Handle heavy objects carefully to prevent dents and scratches.

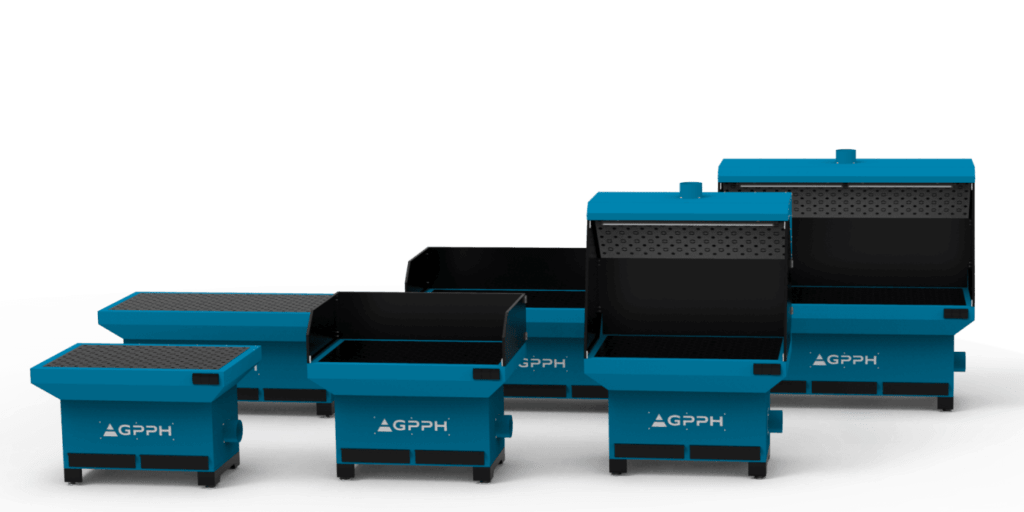

Use of GPPH chemical products

GPPH HD CLEANER is a highly concentrated HD CLEANER that is ideal for daily cleaning. It effectively removes dirt and welding residues and leaves the surface clean. The cleaner also provides long-lasting protection against corrosion.

GPPH PROTECTOR is a preparation that prevents welding spatter from adhering to the table surface. It should be applied before welding work begins, which makes subsequent cleaning much easier.

Summary

Proper care and maintenance of your welding table is crucial to its longevity and functionality. Regular cleaning and the use of high-quality chemicals, such as HD CLEANER or PROTECTOR, ensure that your welding table remains in optimal condition and will last for many years. GPPH's high-quality welding tables are already in themselves a solid basis for efficient work, but their potential can be further increased with the right care and maintenance products.