- +48 573-568-355

- [email protected]

The promotion is valid in selected countries of continental Europe.

PROMOTION STILL ON FOR

ENtiktok en_AU

The automation of welding processes is no longer the exclusive domain of large manufacturing plants. More and more companies are deciding to implement cobots, i.e. collaborative robots that can work side by side with humans.

A welder rarely calls himself a perfectionist. More often, he says “that’s how it should be” or “there’s no other way.” And yet – just look at his workstation, the way he sets up components, or his reaction to the slightest deviation to know one thing: perfectionism in welding is part of everyday life.

Poprawa bezpieczeństwa i higieny pracy to dziś nie tylko obowiązek pracodawcy, ale także inwestycja w zdrowie pracowników i efektywność operacyjną firmy. W 2026 roku Zakład Ubezpieczeń Społecznych ponownie uruchomił konkurs dofinansowań, który ma na celu ograniczenie zagrożeń w miejscu pracy, redukcję wypadków oraz poprawę ergonomii na stanowiskach.

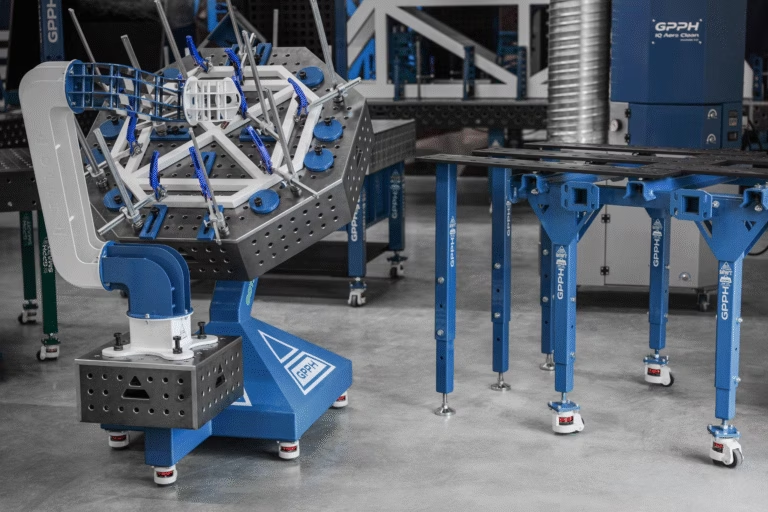

Limited floor space is one of the biggest challenges in welding workshops. Lack of space quickly affects ergonomics, working time and safety. Fortunately, a well-planned workstation allows you to get the most out of even a small area.

Modern welding is increasingly less associated with a single, permanently assigned workplace.

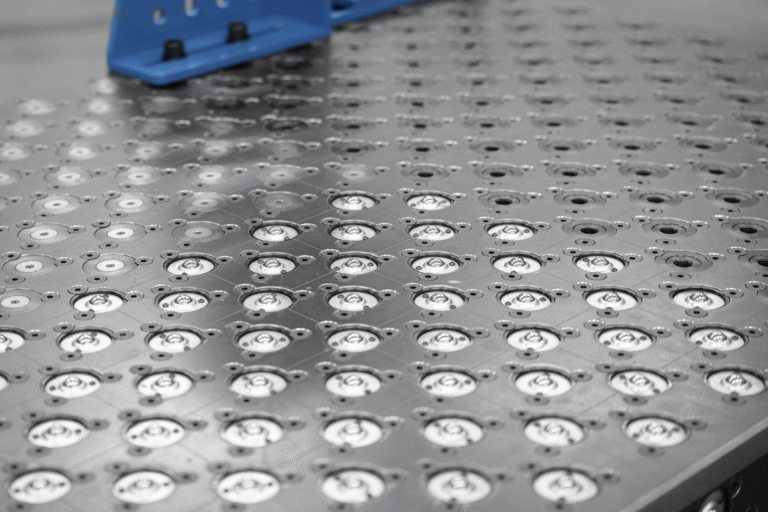

In many workshops, a welding table is treated solely as a work surface. In modern production processes, however, it is a system component that has a direct impact on lead time, repeatability of structures, and the welder’s working comfort. An improperly set up or poorly selected table not only slows down work, but very often generates errors that only become apparent during assembly or quality control.

If you enjoy DIY, welding, experimenting and “doing things your own way”, then you know one thing for sure – a good workshop table is essential.

Welding is a profession that offers more than just stable employment – it is a skill that combines precision with craftsmanship, resulting in structures that truly matter. More and more people, both young and those looking to change careers, are wondering how to enter this world.

Winter in the workshop is a real test—not only for the welder, but also for the equipment and workstation organization. Low temperatures, cold floors, cold steel, and welding fumes that, instead of disappearing… hang in the air.

Learning to weld very often starts with parameters, technology, and the technique of running a weld bead. These are important elements, but in industrial practice the quality of a welder’s work is determined by something more—habits that are formed from the very first contact with the welding workstation.

GPPH S.C. © 2025 All rights reserved.

Podaj swój adres e-mail, aby zachować zawartość koszyka i wrócić do zakupów w dogodnym momencie.