- +48 573-568-355

- [email protected]

The promotion is valid in selected countries of continental Europe.

PROMOTION STILL ON FOR

ENtiktok en_ZA Do you need stainless steel welding tables for your projects? You will find the perfect solution in our range - the GPPH INOX stainless steel welding tables. These tables, available in the PRO (15 mm) and PLUS (12 mm) top series, offer up to 10 different dimensions, allowing you to perfectly adapt your workstation to your individual needs.

The welding tables in the INOX series are made of stainless steel in grade 1.4301, which is not only characterised by its durability and corrosion resistance, but also exceptional electrical conductivity. Thanks to their low electrical resistance (0.73 Ω mm²/m at 20°C), INOX tables provide excellent efficiency when welding stainless steel.

Corrosion resistance and durability are further advantages of stainless steel welding tables. Made from high-quality steel with a high chromium content, they guarantee long-term reliability and eliminate the risk of iron precipitation and corrosion foci. As a result, your constructions will be safe, durable and resistant to external influences.

The GPPH INOX stainless steel tables guarantee precise and accurate construction, without the need for additional adjustments. Their ergonomic design and high quality workmanship enable efficient working while maintaining repeatability and excellent weld quality. The INOX series of tables is also available in versions with feet on feet or on wheels, allowing the workstation to be freely adapted to specific needs and working conditions.

Thanks to the low electrical resistance and exceptional conductivity of stainless steel, GPPH INOX stainless steel welding tables are the ideal solution for industries that require precise and durable stainless steel welding. Regardless of the complexity of the project or the high quality standards, these tables provide professionals with the perfect tool to carry out their work efficiently and precisely.

GPPH stainless welding tables are used in a wide range of jobs and industries where not only a robust and stable work surface is needed, but corrosion resistance and material durability are also required. Here are some examples of industries where our stainless steel welding tables can be used:

GPPH stainless steel welding tables are widely used in a variety of industries where a robust and durable work surface, corrosion resistance and precision and quality workmanship are required. Their versatility and functionality make them ideal for professionals in various fields who are looking for a reliable welding and assembly tool.

The stainless steel welding tables in the INOX series are ideal for a variety of applications where precision, durability and quality of stainless steel construction are of the utmost importance. Each table top in the INOX series is equipped with a practical and precise engraved scale. This unique feature makes it possible to accurately lay out the structure and thus make precise welds - this greatly facilitates the welding process and ensures excellent results.

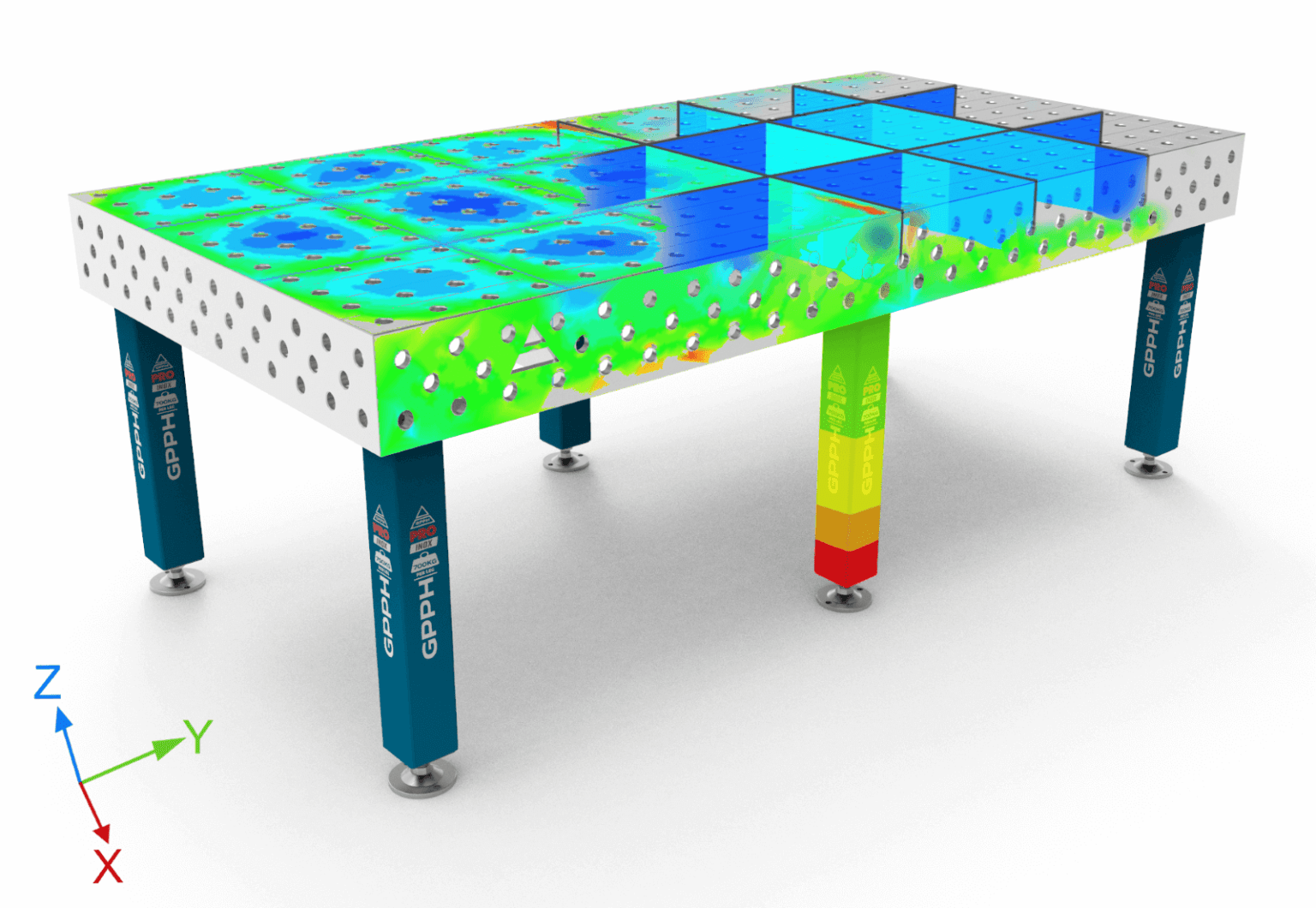

One of the main strengths of the stainless steel GPPH welding tables from the INOX series is the robust and dense ribbing of the tabletop. The use of such ribbing is crucial to achieve a perfectly flat working surface, which is essential in precision welding work. A flatness tolerance of only ±0.3 mm over the entire tabletop dimension confirms the excellent workmanship and attention to detail.

Ribs spaced every 400 mm on average in the tabletop structure ensure stability during work and protect against deformation. As a result, GPPH INOX stainless steel welding tables are able to maintain their perfect geometry over a long period of use, regardless of the intensity of work and loads. The robust and rigid tabletop construction guarantees not only stability but also a precise finish to any welded structure.

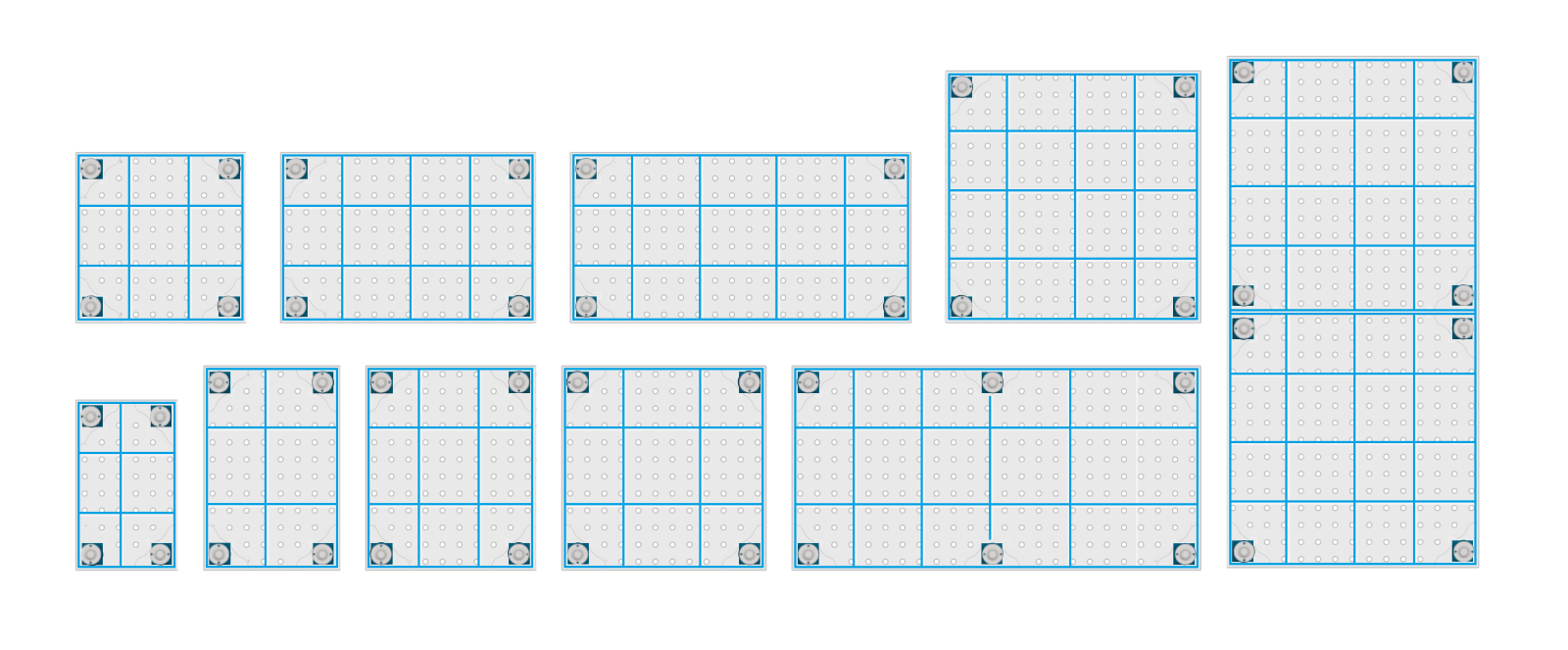

In the INOX series, we offer worktops in two variants: PRO and PLUS, each available in ten different dimensional versions. Choosing the right series depends on your individual needs and requirements. Both variants are characterised by exceptional workmanship, wear resistance and excellent precision, making them indispensable for various types of welding work.

The INOX series is designed to meet the highest standards of quality and performance, giving professional welders and specialists a wide range of applications. Whether you are working on precise, small parts or large and demanding projects, the GPPH INOX stainless steel welding tables will not only provide you with an excellent quality work base, but also comfort, ergonomics and efficiency. Versions with foot or wheeled legs allow you to easily adapt the table to your needs, ensuring maximum comfort and convenience of use.

The stainless steel welding tables of the INOX series are made of stainless steel grade 1.4301, which allows precise welding of stainless steel structures. This material also has excellent electrical conductivity, which will provide you with optimal conditions for welds. The electrical resistance at 20°C is 0.73 (Ω mm²)/m.

The flatness tolerance of the table over the entire table top is only ±0.3 mm in the PLUS INOX and PRO INOX series (provided the table top is correctly levelled). This means that the table's working surface is perfectly flat, enabling precise and efficient welding and assembly.

Each of the GPPH INOX table series, has three rows of openings in the side walls, which increases their functionality and allows diverse tool fixing. The PLUS INOX and PRO INOX series are distinguished by milled and chamfered holes and chamfered holes on the underside, which facilitates precise positioning of the structure and mounting of tools, which in turn translates into productivity and quality of work. The hole tolerance of the PLUS INOX and PRO INOX series is only +0.05 mm, which testifies to the exact workmanship and precision of the tables.

The legs are made of 80x80x4 mm profile in the PLUS INOX series and 100x100x4 mm in the PRO INOX series. The load capacity of the tables is 500 kg per leg in the PLUS INOX series and an impressive 700 kg per leg in the PRO INOX series. This means that these tables are ready to cope with demanding projects and heavy constructions, increasing their versatility.

The PLUS INOX and PRO INOX series have milled top edges, which adds to the aesthetics and professional appearance of the entire structure.Each of the GPPH INOX series offers up to 10 dimensional versions, allowing the table to be tailored to individual needs and applications.

With GPPH INOX stainless steel welding tables, your projects will be carried out precisely and reliably, and your work will become efficient and comfortable. The durable construction and high quality workmanship of these tables will not only provide you with excellent welding results, but also increase productivity and save time in your work.

Parameter | PLUS INOX | PRO INOX |

|---|---|---|

Tolerance on flatness for a table (on the whole worktop)* | ±0,3 mm | ±0,3 mm |

Three grids of holes on the 4 sides | ✓ | ✓ |

Table top thickness | 12 mm | 15 mm |

Chamfered and milled holes | ✓ | ✓ |

Chamfered holes from bottom | ✓ | ✓ |

Holes manufacturing tolerance | +0,05 mm | +0,05 mm |

Leg profile | 80x80x4 mm | 100x100x4 mm |

Capacity | 500 kg/leg | 700 kg/leg |

Total load capacity for a table with 4 legs | 2000 kg | 2800 kg |

Total load capacity for a table with 6 legs | 3000 kg | 4200 kg |

Total load capacity for a table with 8 legs | 4000 kg | 5600 kg |

Milled table top edges | ✓ | ✓ |

Number of dimensional versions | 10 versions | 10 versions |

| Worktop dimensions | Net price SERIA PRO | Net price SERIA PLUS |

|---|---|---|

| 1000x600 | € 4 120 | € 2 990 |

| 1000x1000 | € 5 860 | € 3 990 |

| 1200x800 | € 5 540 | € 3 890 |

| 1200x1000 | € 6 490 | € 4 520 |

| 1200x1200 | € 7 290 | € 5 090 |

| 1500x1000 | € 7 720 | € 5 320 |

| 1500x1480 | € 10 160 | € 6 990 |

| 2000x1000 | € 9 590 | € 6 590 |

| 2400x1200 | € 12 790 | € 8 740 |

| 3000x1480 | € 20 320 | € 13 980 |

| Worktop dimensions | Net price SERIA PRO | Net price SERIA PLUS |

|---|---|---|

| 1000x600 | € 4 540 | € 3 520 |

| 1000x1000 | € 6 290 | € 4 540 |

| 1200x800 | € 5 990 | € 4 290 |

| 1200x1000 | € 6 990 | € 4 990 |

| 1200x1200 | € 7 820 | € 5 590 |

| 1500x1000 | € 8 260 | € 5 860 |

| 1500x1480 | € 10 690 | € 7 540 |

| 2000x1000 | € 10 190 | € 7 160 |

| 2400x1200 | € 13 460 | € 9 390 |

| 3000x1480 | € 21 380 | € 15 080 |

| Worktop dimensions | Net price SERIA PRO | Net price SERIA PLUS |

|---|---|---|

| 1000x600 | € 4 376 | € 3 210 |

| 1000x1000 | € 6 116 | € 4 210 |

| 1200x800 | € 5 796 | € 4 110 |

| 1200x1000 | € 6 746 | € 4 740 |

| 1200x1200 | € 7 546 | € 5 310 |

| 1500x1000 | € 7 976 | € 5 540 |

| 1500x1480 | € 10 416 | € 7 210 |

| 2000x1000 | € 9 846 | € 6 810 |

| 2400x1200 | € 13 174 | € 9 070 |

| 3000x1480 | € 20 832 | € 14 420 |

| Worktop dimensions | Net price SERIA PRO | Net price SERIA PLUS |

|---|---|---|

| 1000x600 | € 4 540 | € 3 740 |

| 1000x1000 | € 6 290 | € 4 760 |

| 1200x800 | € 5 990 | € 4 510 |

| 1200x1000 | € 6 990 | € 5 210 |

| 1200x1200 | € 7 820 | € 5 810 |

| 1500x1000 | € 8 260 | € 6 080 |

| 1500x1480 | € 10 690 | € 7 760 |

| 2000x1000 | € 10 190 | € 7 380 |

| 2400x1200 | € 13 460 | € 9 610 |

| 3000x1480 | € 21 380 | € 16 300 |

Na naszym sklepie istnieje możliwość sfinansowania zakupu stołu poprzez leasing dla klientów biznesowych (od 5 000zł netto) oraz raty 0% dla klientów indywidualnych (limit ratalny to 12 000zł brutto)

GPPH stainless steel welding tables come in both smaller and larger sizes to meet different requirements. We offer tables with dimensions of: 3000x1480 mm*, 2400x1200 mm, 2000x1000 mm, 1500x1480 mm, 1500x1000 mm, 1200x1200 mm, 1200x1000 mm, 1200x800 mm, 1000x1000 mm, 1000x600 mm

Our stainless steel welding tables in a variety of sizes allow you to tailor the workstation to your individual needs and requirements. Whether you need a smaller area for fine detailing or a larger table for ambitious projects, we have the right solution for you.

The right table dimensions will affect the comfort, productivity and precision of your work. Whether you are working in a smaller workshop or a larger production hall, our welding tables with different dimensions will provide you with a solid and stable base for efficient welding and assembly.

We assure you that our GPPH welding tables, available in a wide range of sizes, will meet your expectations and enable you to achieve excellent results in any welding project.

*Welding table with dimension 3000x1480 mm consists of two connected tables with dimension 1500x1480 mm

Wondering what systems and hole grids stainless steel welding tables have? Our range is diverse, giving you the opportunity to tailor your workstation to your individual needs. You will find the perfect solution to enjoy the efficiency and quality of your work on GPPH stainless welding tables.

We offer different hole systems to adapt the tables to different applications:

Our GPPH stainless steel welding tables with robust systems and hole grids will help you customise your workstation to suit your individual needs. High build quality, durability and a variety of options are our guarantee that you will find the perfect solution for your welding tasks. Work on large projects or precise details - we have the right tables to meet your requirements and provide you with excellent results.

GPPH's high-quality stainless steel welding tables are distinguished by their robust ribbing, which plays a key role in ensuring the reliability, stability and flatness of the work surface.

Thanks to the ribs in the tabletop substructure, GPPH welding tables guarantee a perfectly flat working surface. This is important because it eliminates the risk of point deformation, ensuring consistent table geometry and stability during intensive work. An even table surface enables precise welding and assembly, a key aspect for professional welding applications.

The robust ribbing also contributes to the exceptional durability and resistance of GPPH tables to long-term use. This feature ensures that the tables maintain their properties for many years, which translates into savings and reliability in everyday use.

Ribbing is a key element contributing to the excellent flatness and stability of GPPH stainless steel welding tables. This advanced solution allows for precise welding and assembly, minimising the risk of distortion and ensuring reliability over many years of use. GPPH stainless steel welding tables with solid fins are an indispensable tool for professional welders who value excellent quality and efficiency in their work.

The use of a rib distribution, with one rib every 400 mm of side length, is a key element that ensures even stress distribution. This intelligent design guarantees the stability of the welding table and protects it from point deformation. As a result, our tables are not only robust, but also remain consistently durable, even during intensive use.

In the PRO INOX series of stainless tables, the legs are made of a solid 100x100 mm profile, which guarantees reliability and stability during welding and assembly. The PLUS INOX series has legs made of 80x80 mm profile, which are equally solid and robust.

GPPH welding table legs are available in two versions - with feet and with wheels. The version with feet is an excellent option for those who need a fixed and stable workstation. The foot provides a secure hold on the table top, allowing you to focus on precision welding and assembly.

Tables with legs on wheels, on the other hand, are ideal for those who need mobility and flexibility in organising their workspace.

The wheels allow the table to be easily moved around the workshop, making it quick and efficient to adapt the workstation to suit your current needs. In addition, the wheels are equipped with a locking mechanism that keeps the table in a stable position during welding or assembly, ensuring safety and comfort.

Whether you choose a version with feet or on wheels, GPPH welding tables are designed to meet the highest standards of quality and performance. They offer robust and reliable support, adapting to your needs, allowing you to work efficiently and effectively in a variety of conditions.

What is the purpose of the side walls in our welding tables? The side walls in our welding tables offer a number of advantages. Firstly, they allow you to enlarge the working area with extensions or connection cubes, which makes work easier with larger welded components. In addition, they can be used to attach tools and create a base for welded components.

The side walls also allow mobile tool shelves to be hung on them, keeping tools in one place and keeping the work area tidy. They make work more efficient and organised and allow welders to focus on their work without being interrupted unnecessarily to search for tools. This solution is ideal for professional welders who value functionality and efficiency in their work.

Efficiency and precision are key aspects in any welding process, which is why we offer fast assembly bolts for our stainless steel welding tables to ensure maximum functionality and flexibility in tool assembly. Our wide range of mounting assembly bolts includes magnetic assembly bolts, classic quick-mounting bolts and adjustable universal assembly bolts, which are ideal for different types of welding work.

Magnetic assembly bolts are the ideal solution for welders who need complete freedom to mount tools on the table top. Their design allows tools to be repositioned quickly and precisely, and makes assembly extremely simple and intuitive. This makes it quick and easy to adapt the bench to different welding projects.

The classic quick-mounting bolts, on the other hand, are invaluable for jobs where speed and stability in tool clamping are crucial. They allow the welder to save valuable time, which increases productivity. Easy handling and secure tool holding allow the welder to focus on the welding process itself.

Adjustable universal assembly bolts are versatile tools that are ideal for a variety of applications. They can be used to mount tools of different thicknesses and dimensions, giving the welder greater flexibility in their work. They allow three tools to be clamped simultaneously at a single point, making work easier when welding complex structures.

Whatever type of mounting mandrel you choose, you can be sure that it will provide reliability, precision and performance in tool assembly. Our mounting mandrels have been carefully designed and manufactured with the highest attention to quality to meet the expectations of even the most demanding welders.

The fast assembly bolts are available in various versions to suit the chosen welding table series and tool series. Take a look at our graphic, which shows all the available options. Choose the mounting mandrels that meet your individual welding needs.

Check out our milled tools from the PRO and PLUS series, dedicated to stainless steel welding tables. With them, your 2D and 3D designs will be perfectly executed and the whole work process will be significantly shortened!

Optimise your work and achieve repeatable results with milled tools for welding tables. Take a look at our suggestions for ready-made tool sets and enjoy the ease of your work.

Keep your workspace perfectly tidy with our tool trolleys! Focus on working efficiently without worrying about clutter or lost tools.

Achieve perfect organisation with our small tool trolley, which allows you to have all your tools at your fingertips without any hassle.

Need even more capacity? Our large tool trolley will accommodate even the most extensive tool sets. Everything will be organised and ready to use.

GPPH tool trolleys are the key to success at your workplace. Choose the perfect organisation and see how it will positively affect your work result!

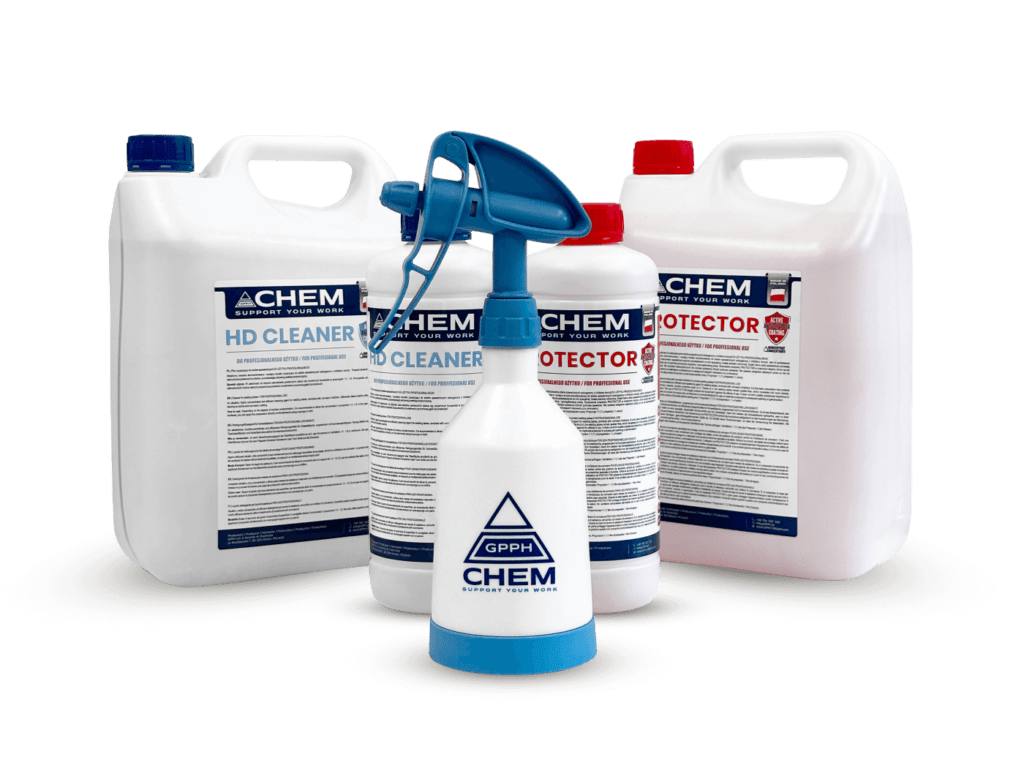

Take care of your table with GPPH CHEM's professional welding chemicals. Our product range includes special products that will provide the right protection and care for your welding table.

Protector is a concentrated anti-scratch concentrate that forms a durable protective film to protect against welding spatter and corrosion. HD Cleaner is an advanced cleaning fluid that effectively removes heavy dirt, leaving the table surface in impeccable condition.

Thanks to GPPH CHEM's professional products, your welding table will remain in excellent condition, which will translate into efficient work and long-lasting use of reliable equipment. Maintain proper care and enjoy the durability and high quality of your table for many years!

GPPH S.C. © 2025 All rights reserved.

Podaj swój adres e-mail, aby zachować zawartość koszyka i wrócić do zakupów w dogodnym momencie.