Efficient welding on welding tables: tips and tricks to increase productivity

Welding on a welding table isn't just about joining metals - it's about optimising techniques and set-ups to effectively achieve the highest quality of fabricated structures. This article discusses practical tips and advice that can significantly improve the efficiency of welding on welding tables, from equipment setup to welding techniques and other key considerations.

Tips for efficient welding on welding tables

Successful welding on a welding table starts with proper setup and preparation of the equipment. Here are some basic tips to keep in mind:

- Equipment configuration: Make sure the welder is correctly configured for the type of welding you are doing (MIG/MAG, TIG or covered electrode). Adjust settings such as voltage, amperage and wire feed speed according to the thickness of the material and welding position. Position the welding table in a well-ventilated area.

- Preparing the workpiece: Thoroughly clean and prepare the surfaces to be welded. Remove rust, paint or impurities that may affect the quality of the weld. Use HD CLEANER from GPPH CHEM for this. Correct fitting of the parts is crucial. Use clamps and other tools on the welding table to secure the workpiece in the desired position.

- Welding techniques: Select the appropriate welding technique based on the joint configuration and material thickness.

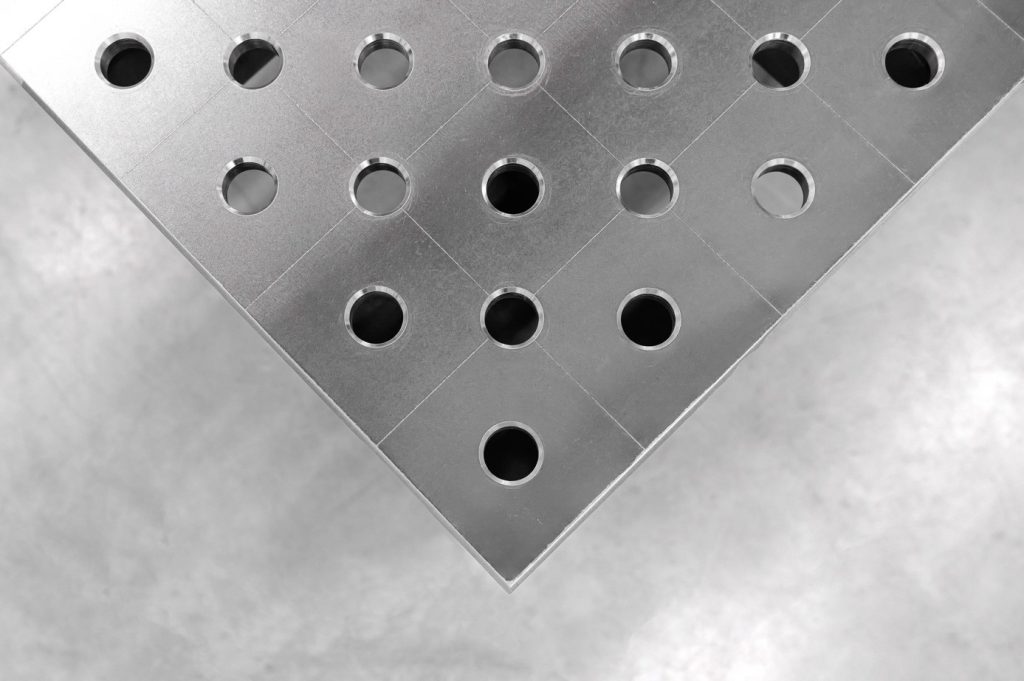

- Mounting workpieces: Use the capabilities of welding tables to securely clamp and position workpieces with tools. Welding tools allow precise alignment and support during welding, levelling distortion.

- Heat control: Carefully manage the heat input to prevent overheating and distortion. Preheating thick materials can help reduce stresses and improve weld fusion. Monitor the weld pool carefully to achieve a uniform stitch appearance and fusion.

Notes on welding on welding tables

In addition to techniques and set-up, several factors contribute to successful welding on welding tables:

- Safety: Always wear appropriate personal protective equipment (PPE), including welding visors, gloves and protective clothing. Ensure adequate ventilation to minimise exposure to welding fumes.

- Quality assurance: Check welds visually and by non-destructive testing methods as necessary to ensure that they comply with specifications. Promptly rectify any defects to maintain high quality standards.

- Continuous improvement: Regularly review and improve welding processes to optimise productivity and quality. Include feedback from weld inspections and collaborate with colleagues to share best practice.

Summary

Successful welding on welding tables requires attention to detail, appropriate application of technology and the use of high-quality equipment. Investing in high quality welding tables, ensures reliability and precision in welding operations. Explore our range of high quality welding tables to find out how innovative solutions can enhance your welding capabilities.

By implementing these tips and considerations, welders can achieve consistent, high-quality fabricated products on welding tables, contributing to efficient production and better results in a variety of industrial applications.