How to choose the right welding table - a guide

Choosing the right welding table is crucial to ensure efficient and safe welding work in an industrial environment. This guide aims to provide an overview of the different types of welding tables, highlighting key features to consider when making a choice and comparing the available models on the market.

Types of welding tables

Welding tables are available in a variety of designs and materials to effectively support diverse welding processes and to adapt to different environmental conditions:

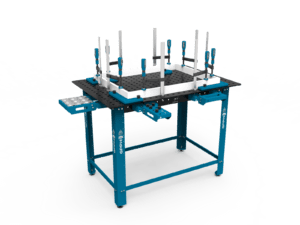

- Traditional tables: robust and made from high quality S355J2+N steel, which is characterised by high strength, durability and resistance. These tables provide a stable base for welding and are suitable for repetitive tasks where precision and stability are paramount.

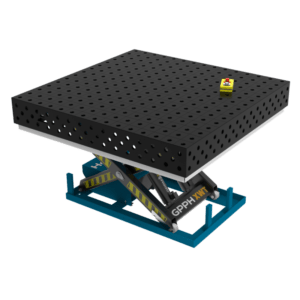

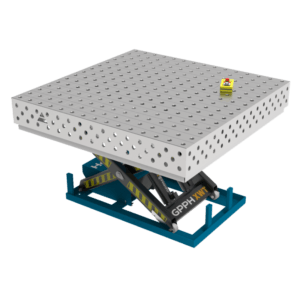

- Adjustable height tables: ideal for ergonomic reasons, they enable welders to work at a comfortable level, reducing strain on the back and shoulders.

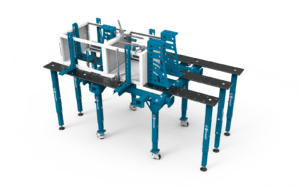

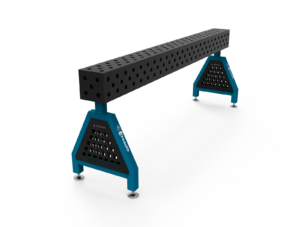

- Welding and assembly tables: They help to make efficient use of the available space while providing the necessary functionality for a variety of tasks. They do not have side walls and are therefore suitable for welding work as an auxiliary table for CNC machines or simply as a versatile surface for various tasks and projects.

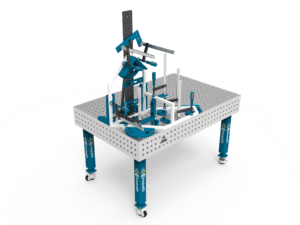

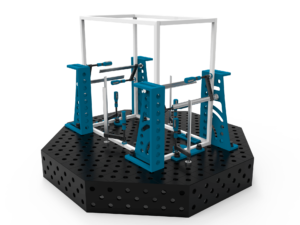

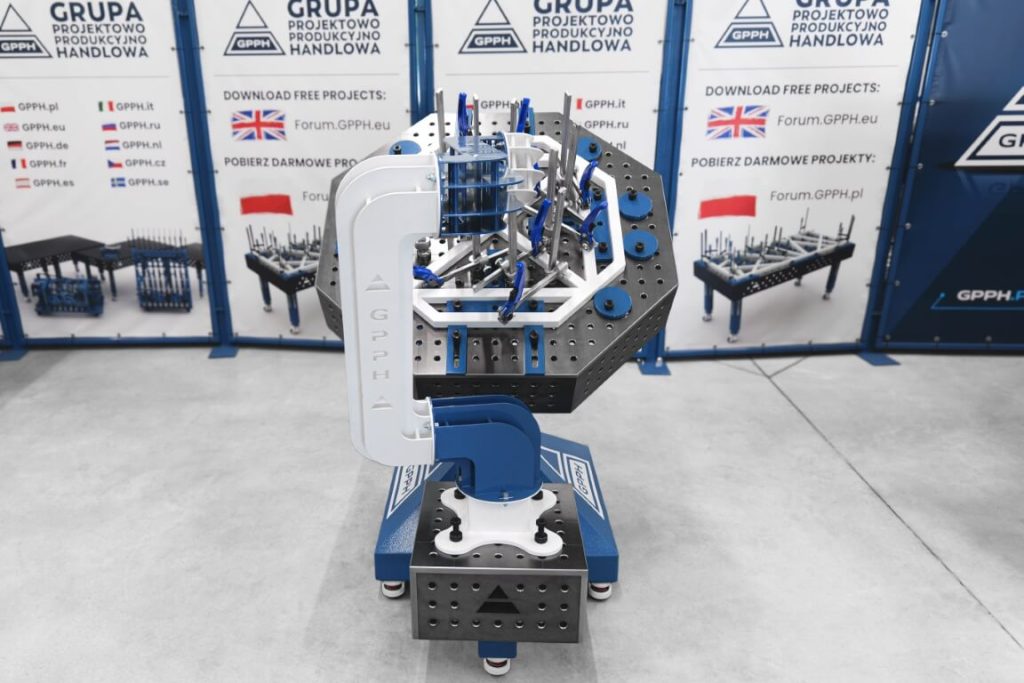

- Rotary tables: can rotate horizontally or vertically, enabling welders to position workpieces at optimum angles without having to constantly change position. They find their use when welding workpieces with complex geometries.

Key features to consider

When choosing a welding table, there are several important features to consider carefully:

- Material: Choose welding tables made of durable materials, such as steel, which will allow them to withstand high temperatures and intensive use.

- Surface: Look for tables with a flat, non-porous surface that makes it easy to clean and prevents the build-up of splinters, which contributes to a clean and hygienic workplace.

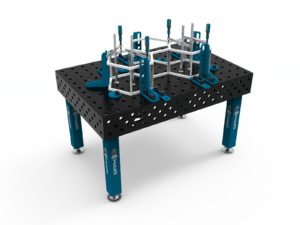

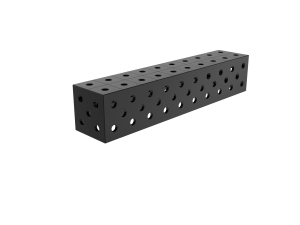

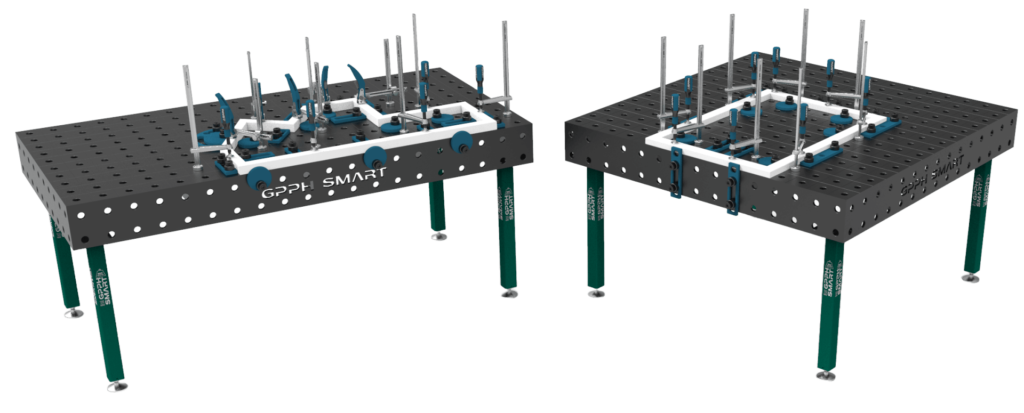

- Fastening options: Tables equipped with fixture holes securely fasten welded parts, increasing productivity and precision of joints.

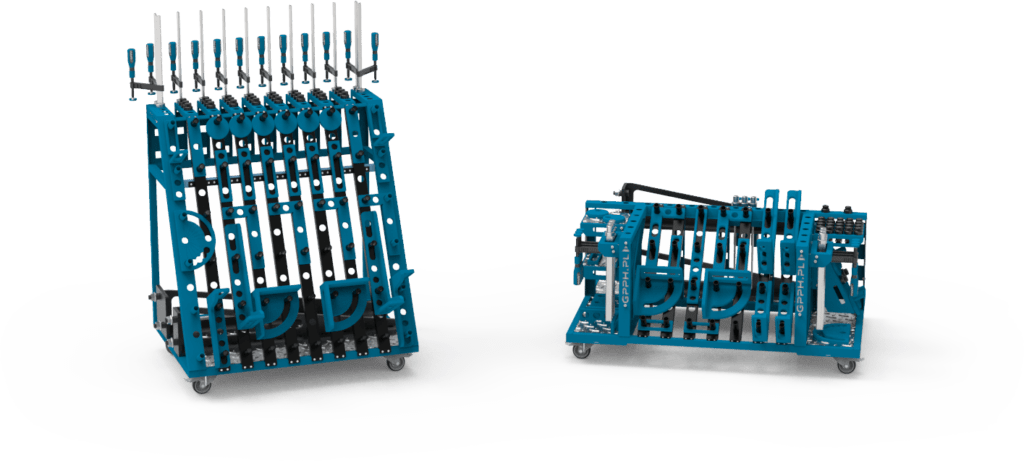

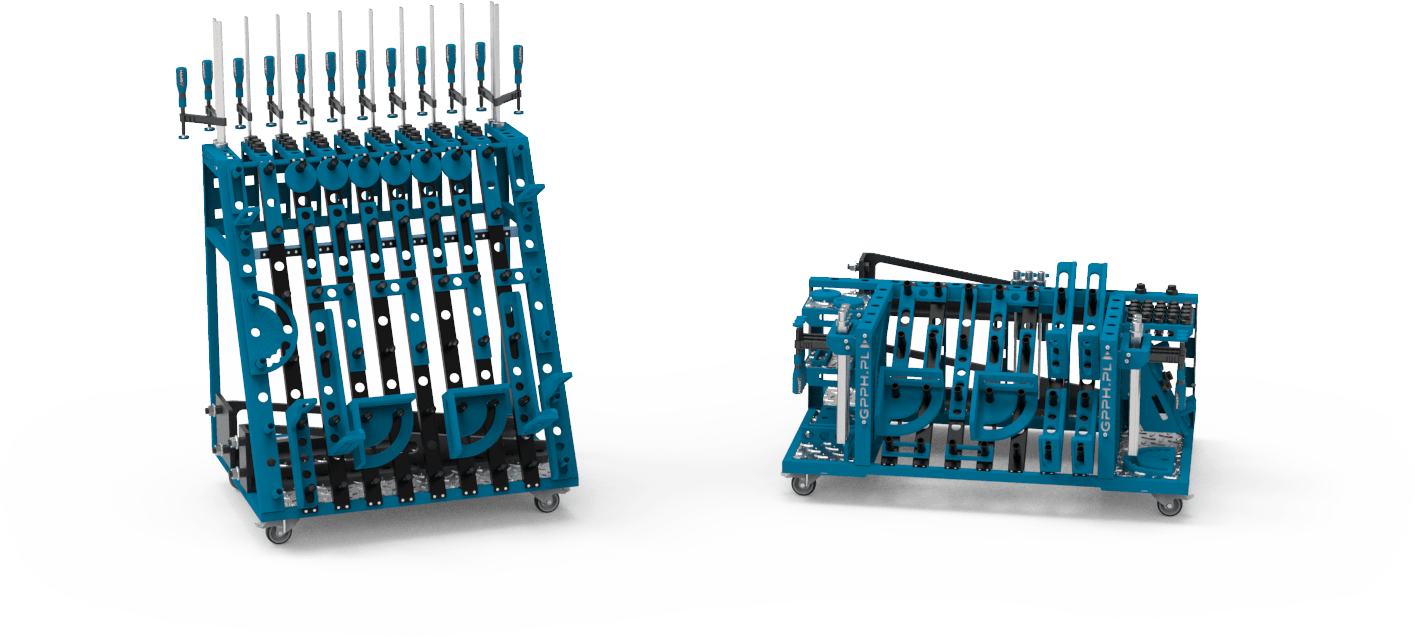

- Mobility: Depending on your needs, consider whether a table with legs on feet or perhaps a version of the table with legs on wheels will suit your business better. Tables in the wheeled version may be more practical if you need to move frequently.

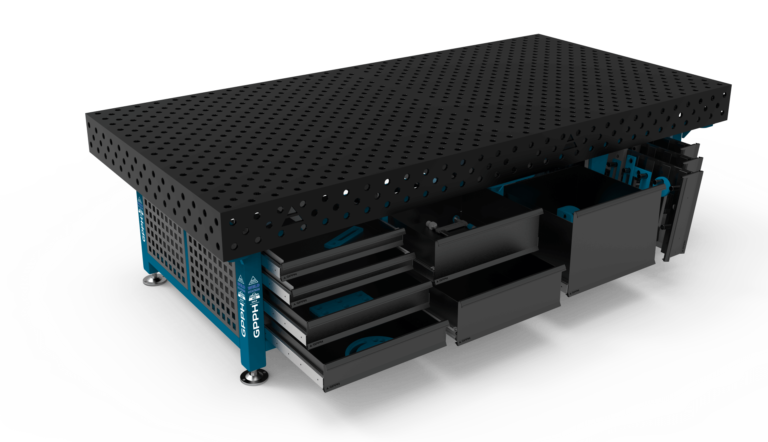

- Accessories: Some welding tables have additional features such as shelves or tool drawers. These additional features can significantly improve the organisation of the work area and efficiency in performing welding tasks.

Market comparison

Before making an informed decision to purchase a welding table, it is important to compare the different models available on the market. Here are some key points to consider when comparing welding tables.

- Manufacturer reputation: Research reputable manufacturers known for producing high-quality welding tables. Companies with a good reputation in the industry often offer tables that meet high quality and safety standards.

- Customer reviews: Read reviews and testimonials from other professionals to assess the reliability and performance of specific models. User reviews can be helpful in determining whether a particular table will meet expectations in your day-to-day work.

- Price vs. features: Evaluate the cost of a table against its features, durability and warranty coverage. There is a balance between price and quality - the cheapest table is not always the best choice. It is important to understand what features and durability a model offers in the context of its price.

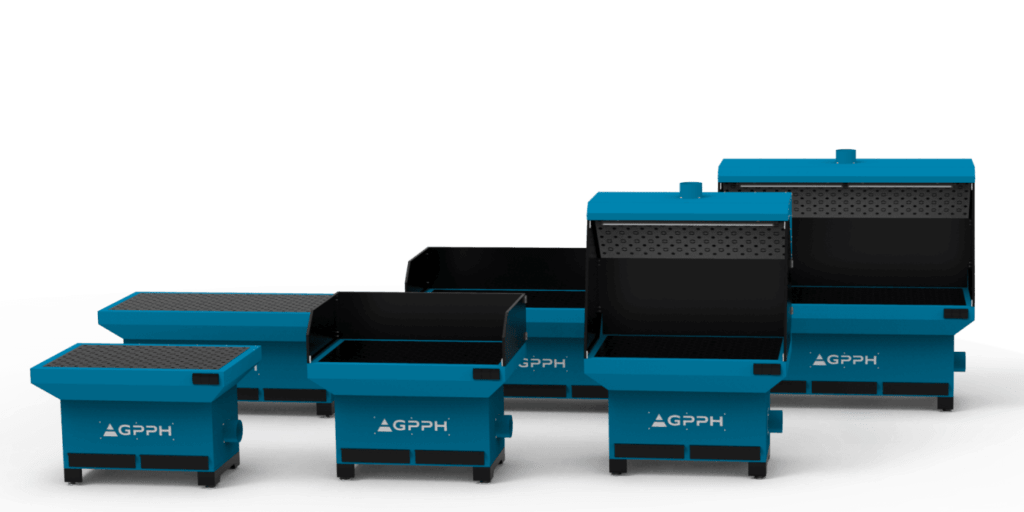

- Customisation options: Some manufacturers, including our company, offer options to customise the table to meet specific customer requirements. The ability to customise a table can be crucial, especially for specialised applications or unusual working conditions.

In conclusion, choosing the right welding table requires taking into account various aspects, keeping in mind the comfort of your work and the optimal conditions for your welding tasks. By investing in the right welding table, you can improve your productivity and ensure a safer working environment.

For expert advice on choosing the best welding table for your needs contact our sales department. Our comprehensive range of industrial solutions includes ergonomic welding tables designed for the best welding results.