- +48 573-568-355

- [email protected]

The promotion is valid in selected countries of continental Europe.

PROMOTION STILL ON FOR

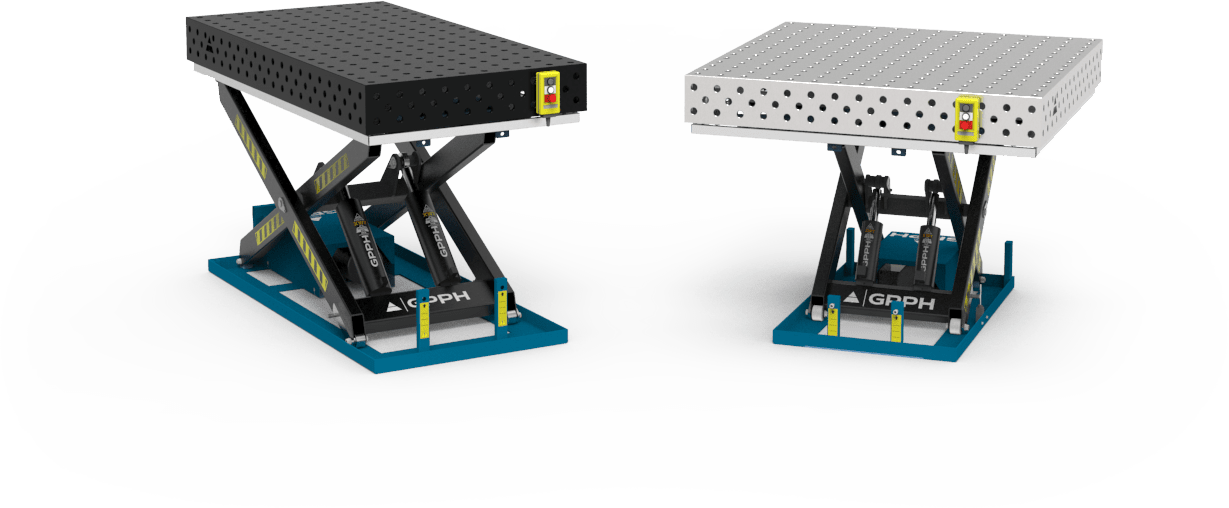

The GPPH XWT Series Welding Table equipped with a hydraulic lifting system is an advanced solution that provides maximum comfort and efficiency. Thanks to the automatic height adjustment of the table top, you can quickly and precisely adjust it to your individual needs, allowing you to achieve the ideal working height. It comes in 4 size versions: 1500x1000, 1500x1480, 2000x1000 and 2400x1200.

Tables with a hydraulic lifting system are found in the GPPH series of welding table tops:

Welding tables with a hydraulic lifting system have many advantages. Above all, they eliminate the need to manually adjust the height of the table top, which significantly speeds up the work process and saves time. You can adjust the height of the table to suit any task, ensuring you have the optimum conditions for precision welding.

The hydraulic lifting system is also extremely safe and reliable. Thanks to overload and safety valves, the risk of damage to the table or injury to the user is minimised. Limit switches provide additional safety, protecting against accidental accidents during lifting and lowering operations of the table top.

There are many benefits to using GPPH welding tables with a hydraulic lifting system. They provide ergonomic working conditions by eliminating the need for manual height adjustment. This is not only convenient, but also reduces fatigue during prolonged welding tasks. In addition, the ability to fine-tune the height of the table top affects the quality and accuracy of welding. This allows you to achieve excellent results, especially on jobs that require special attention to detail.

GPPH welding tables with hydraulic lifting system are the perfect choice for professional welders who value comfort, safety and excellent quality of the work performed. It is an advanced solution that makes the welding process much easier and more efficient, ensuring satisfactory results of the work performed.

Where are welding tables with a hydraulic lifting system used? This innovative solution is an invaluable tool in many industries, allowing for increased work efficiency and operator comfort.

In production halls, welding tables with a hydraulic lifting system are indispensable as auxiliary tools for welding and assembling parts. They allow the height of the worktop to suit the specific task, making it much easier to carry out precise welding and assembly work.

In mechanical and automotive workshops, welding tables with a hydraulic lifting system are ideal for repairing car and machine components. Thanks to the height adjustment of the table top, it is possible to adapt the table comfortably and ergonomically to different types of work.

In the carpentry and furniture industry, GPPH welding tables find their use in the cutting and assembly of furniture joinery components. Thanks to the hydraulic lift, this work becomes more precise and efficient.

GPPH's hydraulic lift welding tables are also available in stainless steel grade 1.4301. This is ideal for welding stainless steel structures, as it significantly increases their versatility and suitability for various industrial sectors, such as the food industry - stainless steel tables are commonly used in the food industry due to their corrosion resistance and ease of maintenance. They are ideal for food preparation, packaging, sorting and other production processes in food plants.

The conclusions are clear - welding tables with hydraulic lifting systems are invaluable tools for many industries and fields. Their advantages allow for increased productivity, precision and convenience, making them the number one choice for professionals for whom the highest quality and productivity are important.

The GPPH XWT series of welding tables equipped with a hydraulic lifting system is an advanced and reliable solution for professional welding applications. And what are the characteristics of our lift tables? Check them out below!

The GPPH XWT series of welding tables with hydraulic lifting system are reliable tools that will meet the expectations of even the most demanding users. Their advanced technical parameters ensure precision, productivity and safety during a variety of welding and assembly tasks.

The GPPH XWT series of welding tables equipped with a hydraulic lifting system is an advanced and reliable solution for professional welding applications. The key technical parameters of the base with hydraulic lifting system are:

In the table you will find information on the most important parameters of lift tables, such as maximum load capacity, lifting time with load, maximum and minimum table height, lift base dimensions and motor power.

| Parameter | 1500x1000 | 1500x1480 | 2000x1000 | 2400x1200 |

|---|---|---|---|---|

Max. load capacity [kg] | 1600 | 1500 | 3500 | 3400 |

Max. load capacity [kg] | 1400 | 1200 | 3200 | 2900 |

Lifting time with a load [s] | 20-25 | 20-25 | 30-40 | 30-40 |

Max. table height [mm] | 1150 | 1450 | 1200 | 1550 |

Min. table height [mm] | 480 | 480 | 550 | 550 |

Dimensions of the base of the lifting [mm] | 1220x785 | 1220x785 | 1863x890 | 1863x890 |

Motor power [kW] | 2.2 | 2.2 | 2.2 | 2.2 |

| Dimension [mm] | Net price EXPERT | Net price PRO | Net price PLUS | Net price ECO |

|---|---|---|---|---|

| 1500x1000 | $ 5 990 | $ 5 390 | $ 4 460 | $ 3 790 |

| 1500x1480 | $ 7 190 | $ 6 060 | $ 4 960 | $ 4 290 |

| 2000x1000 | $ 7 620 | $ 6 560 | $ 5 560 | $ 4 960 |

| 2400x1200 | $ 9 090 | $ 7 820 | $ 6 490 | $ 5 720 |

| Dimension [mm] | Net price EXPERT | Net price PRO | Net price PLUS | Net price ECO |

|---|---|---|---|---|

| 1500x1000 | $ 6 590 | $ 6 360 | $ 4 790 | $ 4 020 |

| 1500x1480 | $ 7 490 | $ 6 460 | $ 5 360 | $ 4 560 |

| 2000x1000 | $ 7 890 | $ 6 990 | $ 5 960 | $ 5 220 |

| 2400x1200 | $ 9 390 | $ 8 320 | $ 6 920 | $ 6 040 |

| Dimension [mm] | Net price PRO INOX | Net price PLUS INOX |

|---|---|---|

| 1500x1000 | $ 11 360 | $ 8 560 |

| 1500x1480 | $ 14 360 | $ 10 360 |

| 2000x1000 | $ 14 390 | $ 10 890 |

| 2400x1200 | $ 18 490 | $ 13 790 |

| Dimension [mm] | Net price PRO INOX | Net price PLUS INOX |

|---|---|---|

| 1500x1000 | $ 11 990 | $ 9 190 |

| 1500x1480 | $ 14 990 | $ 11 290 |

| 2000x1000 | $ 15 090 | $ 11 560 |

| 2400x1200 | $ 19 260 | $ 14 560 |

Discover the advanced capabilities of our welding tables with hydraulic lifting system, available in various dimensions such as 1500x1000, 1500x1480, 2000x1000 and 2400x1200.

The large size of the work surface allows flexibility and versatility in a variety of applications. This allows you to work comfortably with large workpieces, making precise welding operations easier. Production efficiency increases as more parts can be assembled and welded simultaneously.

The lift table dimensions we offer are an excellent support for complex spatial constructions and in the metal and steel industry. In addition, these tables are ideal for repair and overhaul work and in machine and plant manufacture, where they ensure precise assembly and welding.

When you choose our hydraulic lift tables, you gain a reliable tool for a variety of welding and assembly tasks that translates into efficiency, precision and convenience.

Our hydraulic lift table tops offer different systems and hole grids to adapt to different needs and types of work. Depending on your requirements and the nature of your projects, you can choose from several options.

With these different system and hole grid options, our hydraulic lift tables are ideal for a wide range of applications, providing convenience, flexibility and efficiency for a variety of welding and assembly work.

Our tables with a hydraulic lifting system equipped with tops from the PRO, PLUS, ECO, PRO INOX or PLUS INOX series are characterised by a solid ribbed worktop. This ribbing reinforces the tabletop by means of vertical and horizontal ribs in the substructure, which increase its rigidity and load-bearing capacity.

Thanks to the robust ribbing, our tables are able to withstand heavy loads and provide a stable and flat base for welding and assembly work. This ribbing ensures that loads are evenly distributed over the entire table top surface, resulting in no deformation and a long table life.

The ribbed table tops, which are compatible with a base with hydraulic lifting, provide a reliable solution for professional welding applications, providing a solid base for precise and demanding work.

The lift used on welding tables with a hydraulic lifting system is an advanced device with impressive technical features. With a power supply of 400 V and a rotation of 1400 rpm, it provides fast and effective lifting and lowering of the table top.

The lifter is equipped with protection class IP54, which guarantees effective protection against dust and water, which is crucial in harsh workshop environments. In addition, insulation class F ensures safe operation and minimises the risk of the unit overheating.

Thanks to its advanced technical features, the lifter demonstrates not only high performance, but also durability and reliability over a long period of use. It is an indispensable device that enables the welding table top to be adjusted smoothly and precisely, ensuring comfortable working conditions and excellent results during a variety of welding and assembly tasks.

Welding tables with a hydraulic lifting system are available, among others, in the PRO INOX and PLUS INOX series of worktops, which are characterised by their stainless-steel execution, whose corrosion resistance makes them ideal for applications in the food, pharmaceutical and chemical industries, and wherever a hygienic work surface and durability in aggressive environments are required.

Fast assembly bolts are tools that enable tools to be mounted quickly and securely on tables with hydraulic lifting systems. We offer various types of mandrels, such as magnetic assembly bolts, classic quick-mounting bolts and universal adjustable assembly bolts. Choosing the right type depends on your needs and the type of tool.

Magnetic assembly bolts are ideal for mounting tools anywhere on the table top, allowing better use of the work surface. The classic quick-mounting assembly bolts, on the other hand, allow tools to be quickly and securely connected to each other and to the table top. Adjustable universal assembly bolts allow tools of different thicknesses to be clamped and are ideal for supporting welded structures.

Depending on the table and tool series, the fast assembly bolts come in different versions to ensure proper compatibility.

The collaboration of welding tables with a hydraulic lifting system with GPPH milled tools will allow you to achieve maximum precision in every project. Reduce working time and improve the quality of your designs with this ideal combination!

Create an ergonomic and efficient working environment with our tools. Choose from ready-made welding table tool sets or compose your own set and gain convenience in a variety of constructions.

Our tool trolleys are your tools for perfect organisation at your workstation. Focus on action while we keep things tidy.

Forget the hassle of searching for tools. Our small tool trolley offers a practical solution for organising everything in one place.

The large tool trolley is your place for a full set of tools, organised and ready for action. Take advantage of the opportunity to organise them as much as possible.

GPPH tool trolleys are the choice of professionals who know that order is the key to success. Focus on achieving great results with our solutions!

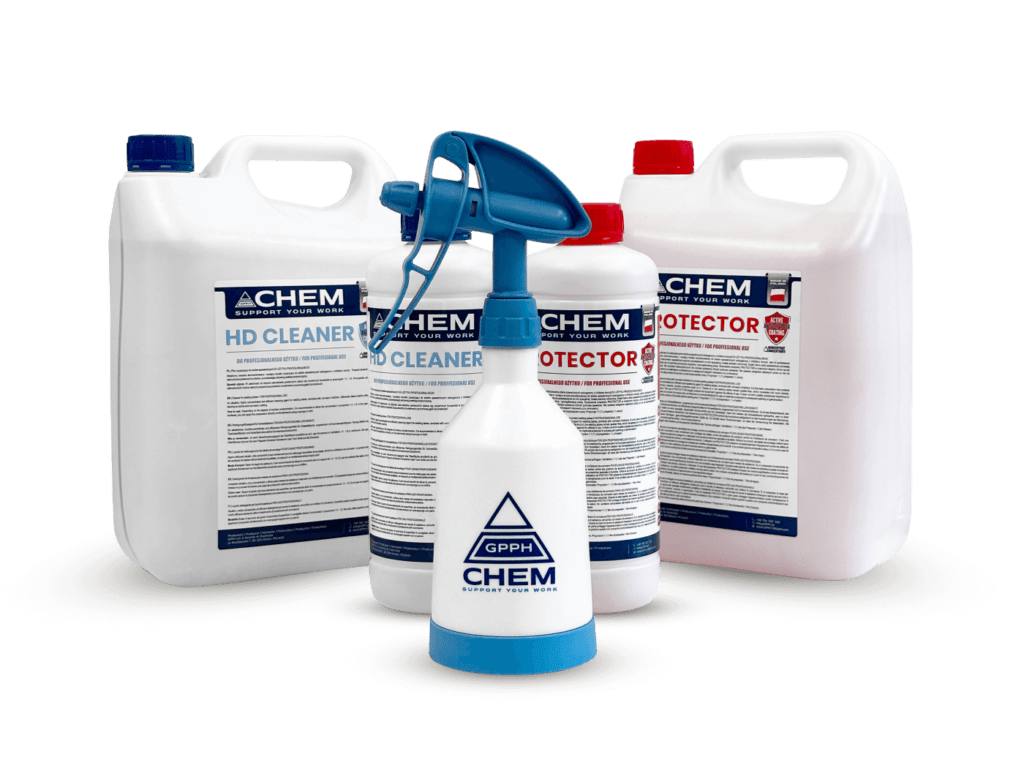

Professional welding tables require professional care products. GPPH CHEM offers Protector and HD Cleaner products to take care of the quality of your table.

Protector is a concentrated anti-scratch concentrate that forms a durable protective film to protect against welding spatter and corrosion. HD Cleaner is an advanced cleaning fluid that effectively removes heavy dirt, leaving the table surface in impeccable condition.

Trust GPPH CHEM professional chemicals to take care of the perfect condition of your welding table, positively influencing the efficiency of your work and the long-term use of your reliable equipment. Don't forget to take proper care to enjoy the durability and high quality of your welding table for many years!

GPPH S.C. © 2025 All rights reserved.

Podaj swój adres e-mail, aby zachować zawartość koszyka i wrócić do zakupów w dogodnym momencie.