Practical tips for welding on the welding table

Welding on a welding table requires attention to detail and proper preparation to ensure quality welds. This article provides practical advice on preparing the welding table, choosing materials and tools, and solving common welding problems to achieve optimal results.

Preparation of the welding table

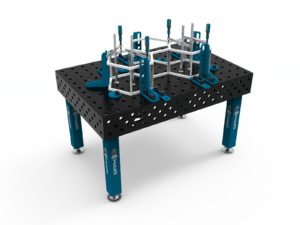

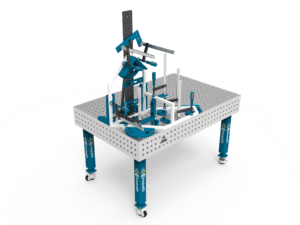

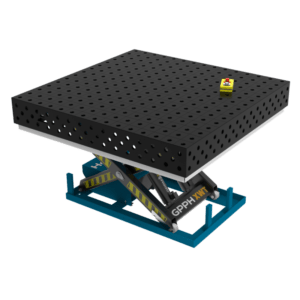

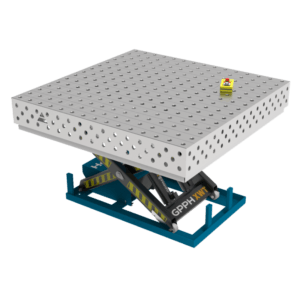

Preparing the welding table is crucial to ensure a stable and safe workplace:

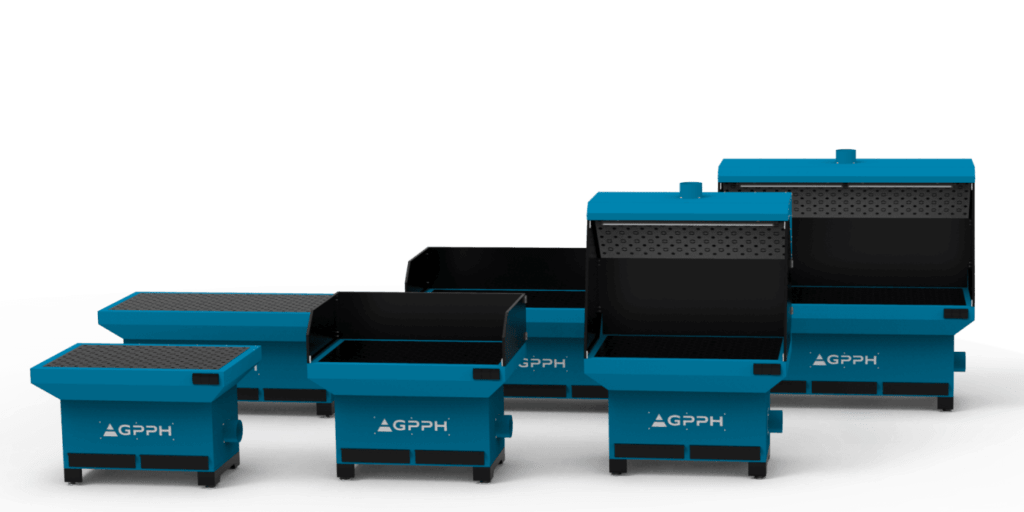

- Cleanliness: Before starting any welding project, the welding table should be thoroughly cleaned to remove oil and any debris that could affect the quality of the weld. A clean surface promotes better adhesion and reduces the risk of defects. For cleaning welding tables, HD CLEANER from GPPH CHEM works best.

- Configuration: Set up the welding table in a well-ventilated area with adequate space to manoeuvre and access to the necessary tools and materials. Make sure the table is level and stable to prevent vibrations that could affect welding accuracy.

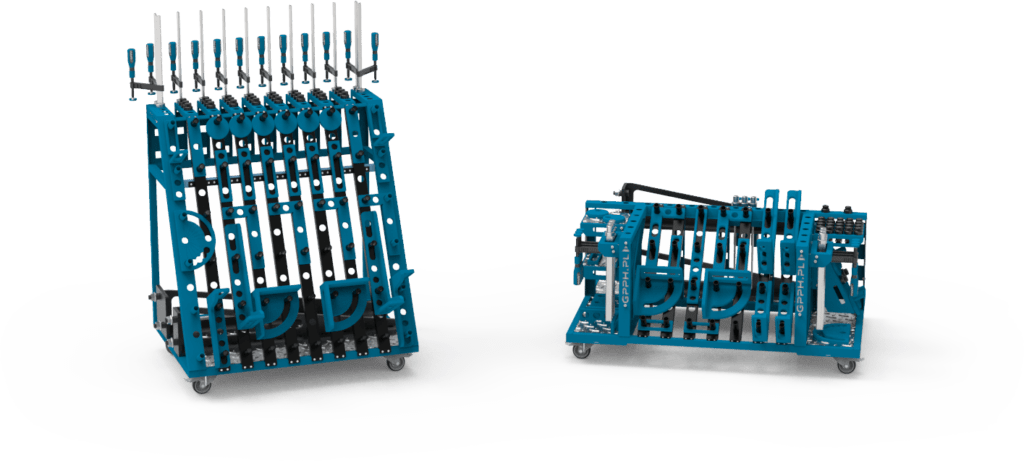

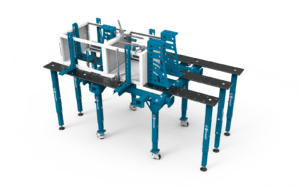

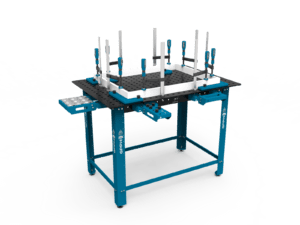

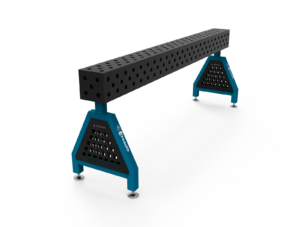

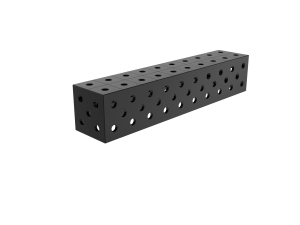

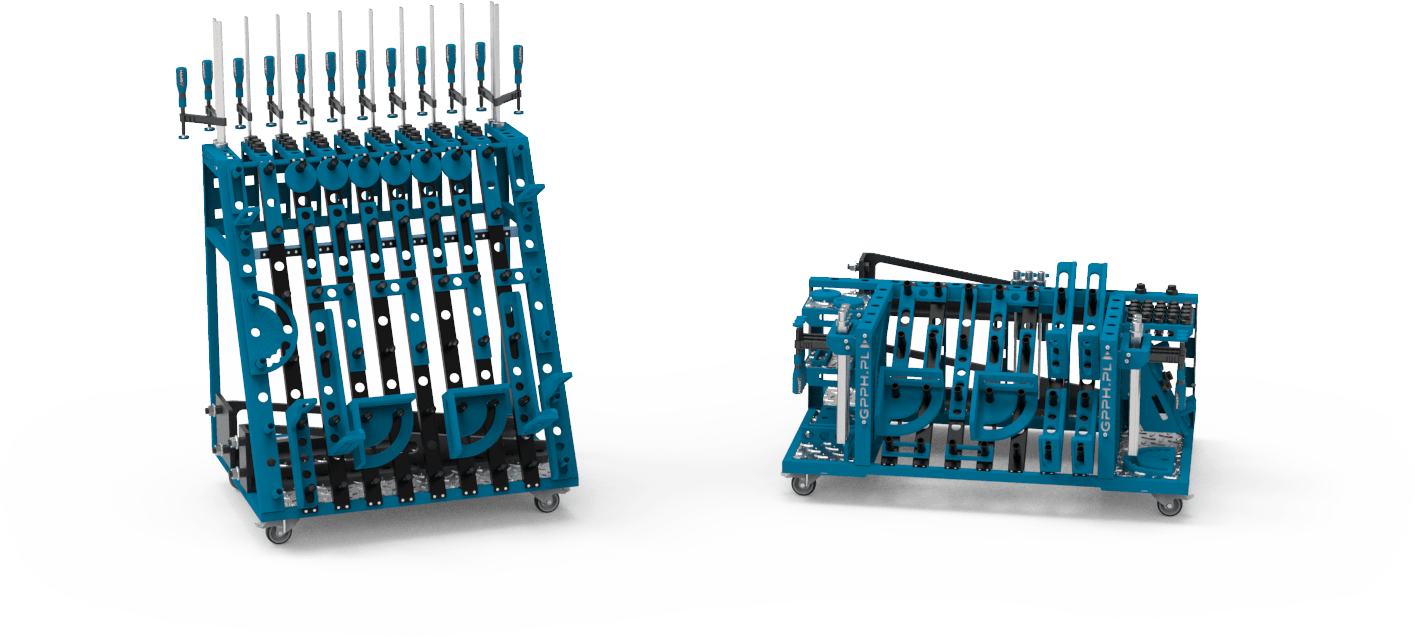

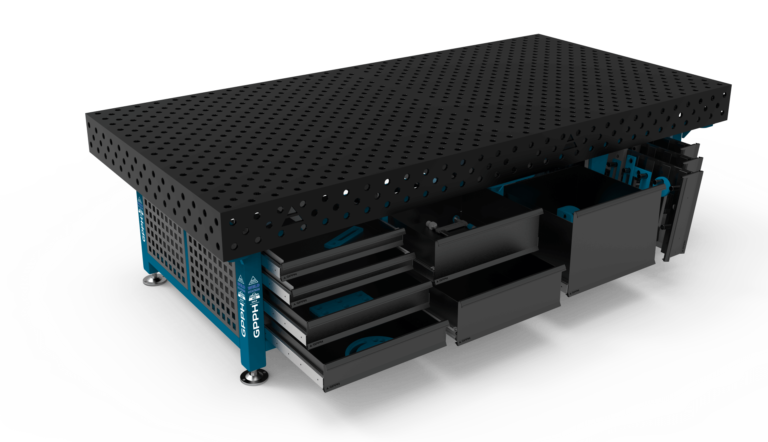

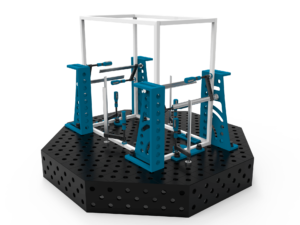

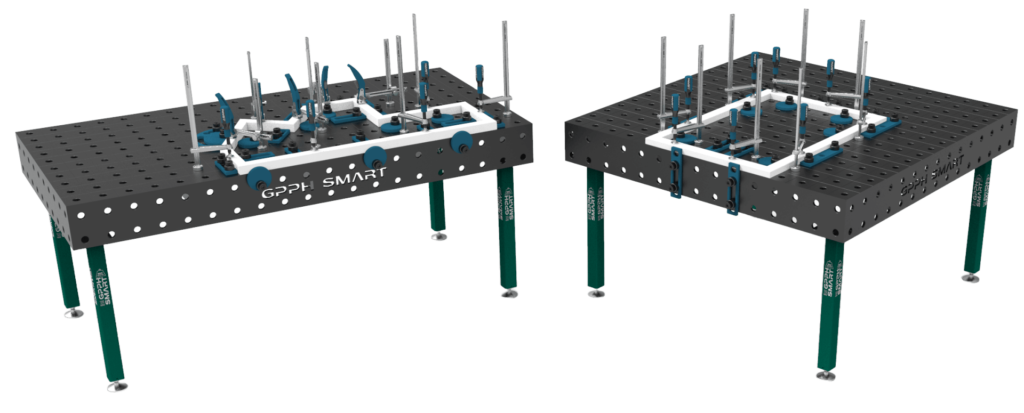

- Fixing: Use the right welding tools to firmly fix workpieces on the welding table. Adjustable clamps, mandrels, flat tools and spatial tools, such as those offered by GPPH, allow precise alignment and support during welding work.

Selection of materials and tools

Choosing the right materials and tools is crucial to achieving strong welds:

- Material compatibility: Select welding consumables that are compatible with the metals to be joined. Ensure that the filler material matches the properties of the metal to maintain the strength and integrity of the weld.

- Material compatibility: Select welding consumables that are compatible with the metals to be joined. Ensure that the filler material matches the properties of the metal to maintain the strength and integrity of the weld.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including welding visors, gloves and protective clothing, to protect against sparks, UV radiation and welding fumes.

Solving typical welding problems

Despite careful preparation, welders can encounter typical problems when welding on a welding table:

- Welding spatter: Minimise welding spatter by adjusting welding parameters and ensuring a clean work surface. It is best to use special GPPH CHEM welding chemistry to reduce the build-up of spatter on the welding table.

- Distortion: Prevent workpiece distortion by controlling heat input and strategically using clamps to minimise movement during welding. Preheating thick materials can help reduce stress and distortion.

- Porosity: Solve porosity problems by ensuring adequate gas coverage (for MIG and TIG welding) and using clean filler materials. Avoid welding in windy conditions, which can interfere with shielding gas flow.

Mastering the art of welding on a welding table requires meticulous preparation, the right tools and proactive problem-solving. Investing in high-quality welding tables, ensures reliability and precision in a variety of welding applications.

By following these practical tips and using high-quality equipment, welders can consistently produce high-quality welds on welding tables, contributing to productivity and excellence in industrial welding operations.