GPPH welding tables set new standards in flatness and working comfort, offering a wide range of functionalities. The dense ribbing, made at intervals of 400 mm on average, is one of the key elements of their design, which specifically determines the ideal flatness of the tables. Below are the various aspects affected by the dense ribbing:

- Structural reinforcement: Thanks to the dense ribbing, the structure of the GPPH welding table is characterised by greater strength and stability. This translates into resistance to overloading, vibration and a longer table life.

- Reduced displacement: The use of numerous ribs prevents deformation and displacement during operation, so that the perfectly flat GPPH welding table maintains its flatness and precision, even under heavy loads or extreme temperatures.

- Resistance to thermal distortion: the dense ribbing also helps to dissipate the heat generated during welding processes. This makes it possible to avoid potential thermal distortion, which could affect the quality and precision of the work on the table.

- Excellent support for workpieces: The dense ribbing of the GPPH welding tables distributes the clamping forces evenly and increases stability, improving the attachment of workpieces to the table surface. This solution contributes to the efficient use of the table’s working surface.

In summary, the dense ribbing used in GPPH welding tables affects their accuracy, stability and durability, resulting in high quality work and a better user experience. This welding table design is an innovative and functional approach to the future of welding.

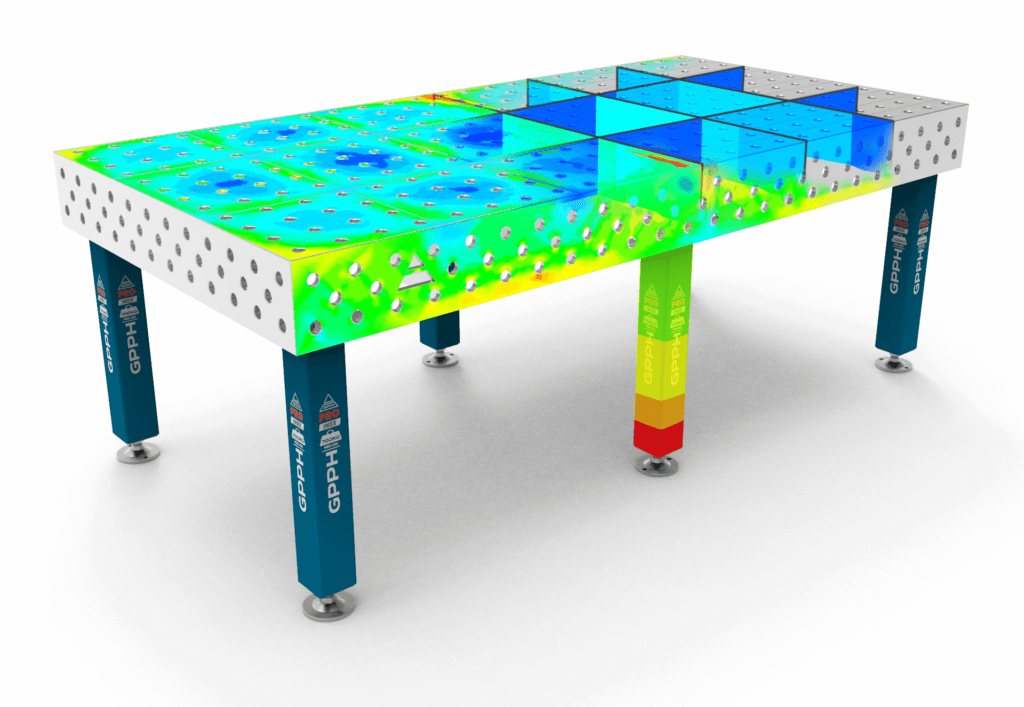

FEM analysis

The distribution of the ribs, where on average there is one rib for every 400 mm of side length, ensures linear stress distribution. The weight of the structure welded on the table top, will be evenly distributed over the entire surface. This prevents point deformation and articulation of the entire table structure.