Today's welding workshops require not only qualified staff, but also equipment and accessories of the highest quality. GPPH welding tables, combined with dedicated tools, create a solid foundation for efficient and precise work. Let's take a closer look at GPPH tools and accessories that simplify the welding and assembly process, making it more efficient.

Clamps - reliability and stability

Clamps are an indispensable part of any welding table. The clamps we offer are characterised by:

- Durable construction - made from high-quality materials, ensuring long-lasting use.

- Ergonomic design - facilitates quick attachment and removal of components.

- Versatility - offered in many sizes and configurations to suit a variety of needs.

Advantages of using GPPH clamps:

- Precision clamping of components during welding.

- Reduction of vibrations and displacements, which translates into the quality of the structures produced.

- Time-saving thanks to quick assembly.

Flat tools - welder's essential equipment

Flat tools are a wide range of accessories that enable precise alignment and fixing of flat components. The range includes:

- Angle squares, stoppers - for positioning workpieces on the welding table at a specific point.

Advantages of using GPPH flat tools:

- Precision in the placement of elements.

- Increased safety of the work due to the stable mounting.

Spatial tools - three-dimensional precision

For more advanced projects, where fixing components in three-dimensional space is required, we offer spatial tools:

- Angle brackets, prisms - for fixing components and building spatial structures (angle brackets) and positioning components at a fixed angle (prisms).

- Extensions, cubes - allowing a stable table extension of the welding table.

Strengths of GPPH spatial tools:

- Visibility in applications.

- Customisation possible for individual project needs.

- Facilitate work on complex structures.

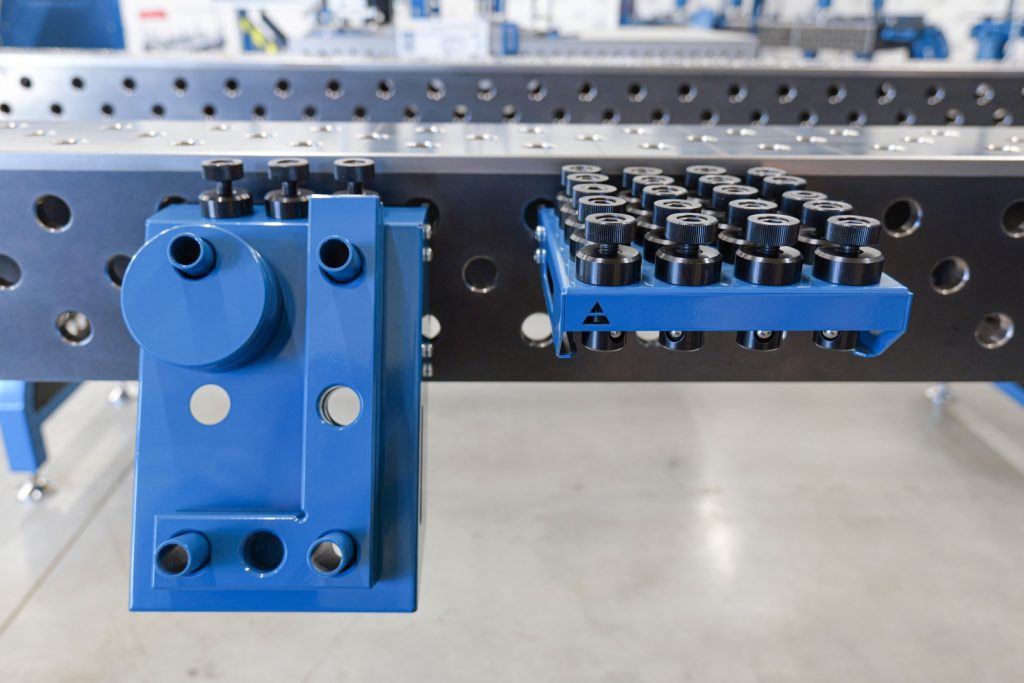

Fast assembly bolts - significant component

Fast assembly bolts are extremely important accessories in the welding process:

- Accurate attachment of tools and therefore precise positioning of components on the table.

- Stabilisation during welding.

Advantages of GPPH fast assembly bolts:

- High precision workmanship.

- Durability thanks to the use of robust materials.

- Ease of use and integration with other tools.

We offer a variety of mounting pins and pins. Among others, fast assembly bolts, magnetic fast assembly bolts and mounting pins. They are all made from the best quality materials, so they will last for many years.

Other accessories - completeness of the GPPH range

In addition to the tools listed, we offer a range of other accessories to complete the welding table equipment, such as:

- Mobile shelves - these keep key accessories close at hand for increased efficiency and convenience, e.g. a fast assembly bolt shelf or clamp shelf. The tool shelves can be hung on the side of the welding table, on a tool trolley or placed on the work surface.

Impact of GPPH tools on work efficiency

Choosing the right tools has a direct impact on:

- Quality of manufactured structures - precise fixing eliminates errors.

- Speed of work - ergonomic tools reduce operation time.

- Safety - stable fixing minimises the risk of accidents.

- Cost savings - durable tools reduce the need for frequent equipment replacement.

Summary

Welding table tools are an investment that quickly pays for itself through, increased efficiency and quality of work in the workshop. The wide range of accessories allows each welder to customise the workstation to their own needs, resulting in better results and greater job satisfaction.