Essential tools and accessories for welding tables

Welding tables are an essential part of any welding setup, providing a stable and versatile surface for a variety of welding tasks. However, the functionality and performance of these tables can be greatly enhanced with the right tools and accessories. This article discusses the necessary tooling for welding tables and how they can enhance your workflow.

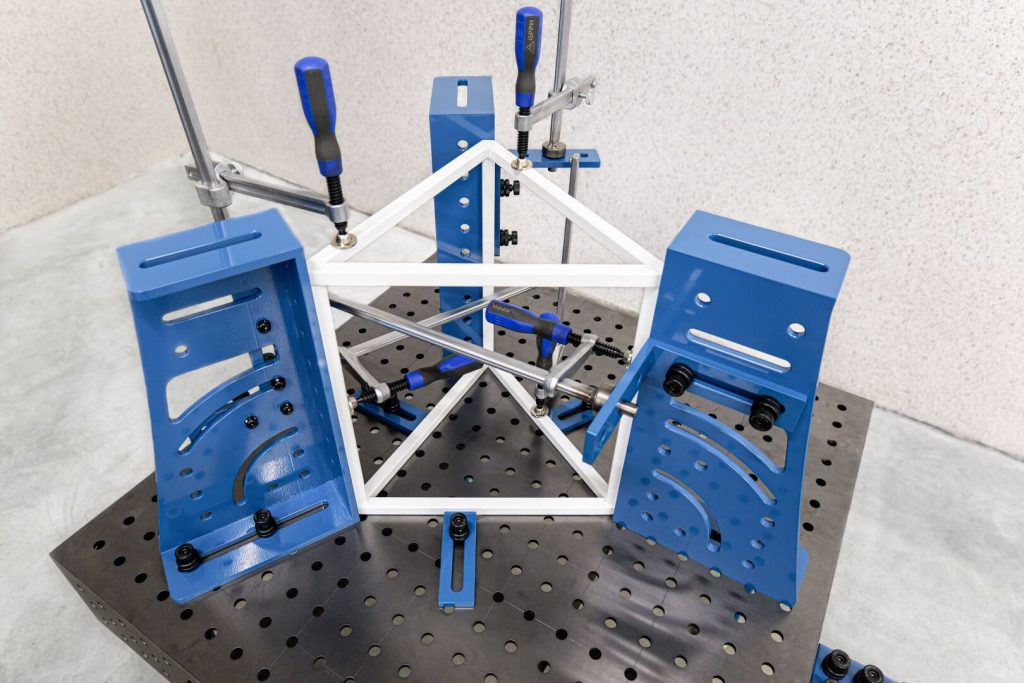

Clamping tools

1. Fastening clamps: Fastening clamps are essential for securing workpieces during welding. They ensure stability, precision and safety.

- Fastening clamps with lever: offer strong, fast clamping mechanisms, making them ideal for repetitive tasks.

- Fastening clamps with variable throat depth clamp: are adjustable, necessary to hold workpieces firmly in place, prevents movement during welding.

2. Mounting bolts: tools that enable tools to be quickly and firmly connected to each other or attached to a table top.

- Magnetic bolts: allow instant attachment of tools or components in any location on the table, eliminating the need for mounting holes.

- Quick-mounting bolts: designed for fixing tools on the welding table.

Positioning tools

1. Flat tools: extremely important tools that are used for positioning and fixing welded components. .

- Stoppers: properly selected and applied, enable optimum results to be achieved during welding, which is particularly important for small parts or thin materials.

- Angle precision squares: Ideal for maintaining 90 degree angles. The use of a winkle also allows the creation of three-dimensional structures with the correct angles between welded parts.

2. Spatial tools: designed for positioning and fixing of spatial weldments on the welding table.

- Angle brackets: are ideal for positioning a variety of components, controlling angles, supporting precision structural alignment and checking geometry.

- Welding prisms: tools that allow precise positioning of parts to be welded at the correct angle.

Increasing the surface area

1. Accessories increasing working surface of the welding table, while enabling it to remain functional.

- Extensions: increase working surface of the welding table. Equipped with hole grids for tool fixing.q

- Connectors/Cubes: designed to connect two welding tables while maintaining their functionality. They make it possible to create personalised welding stations by connecting any number of tables, allowing you to adapt your workspace to the specifics of your project.

- Welding supports: they make it possible to increase the working space, which promotes more ergonomic and comfortable working conditions during welding. They guarantee the stability and strength necessary for precise and complex welding projects.

Accessories for welding tables

1. Shelves and tool trolleys: Organising tools and accessories is crucial to maintaining an efficient workplace.

- Mobile tool shelves: ensure that all the tools and accessories you need are always within easy reach. They can be easily hung on a tool trolley, placed on the side of a welding table top or simply placed on the table top.

- Tool trolleys: Designed to store tools and accessories, they improve organisation and accessibility.

2. Storage drawers: Secure storage of welding equipment and consumables is essential to keep things tidy and protect valuable tools.

- Tool storage drawers: positioned under the welding table make sure all tools are close at hand. Ideal for small workshop spaces where there is no room for a tool trolley.

Summary

Optimising the welding table with the right tools and accessories can significantly improve both productivity and quality of welding tasks. Tooling plays a key role in improving workflow and precision. By investing in these essential tools, welders can create a more productive, safe and organised workplace, which ultimately leads to better welding results.

For more information, visit the accessories for welding tables.