Welding process automation is playing an increasingly important role in today's industry, especially where precision and efficiency are key. To meet these needs, GPPH is unveiling its new octagonal table (OCT) series, specifically designed for an industry that relies on robotisation and automation of welding processes.

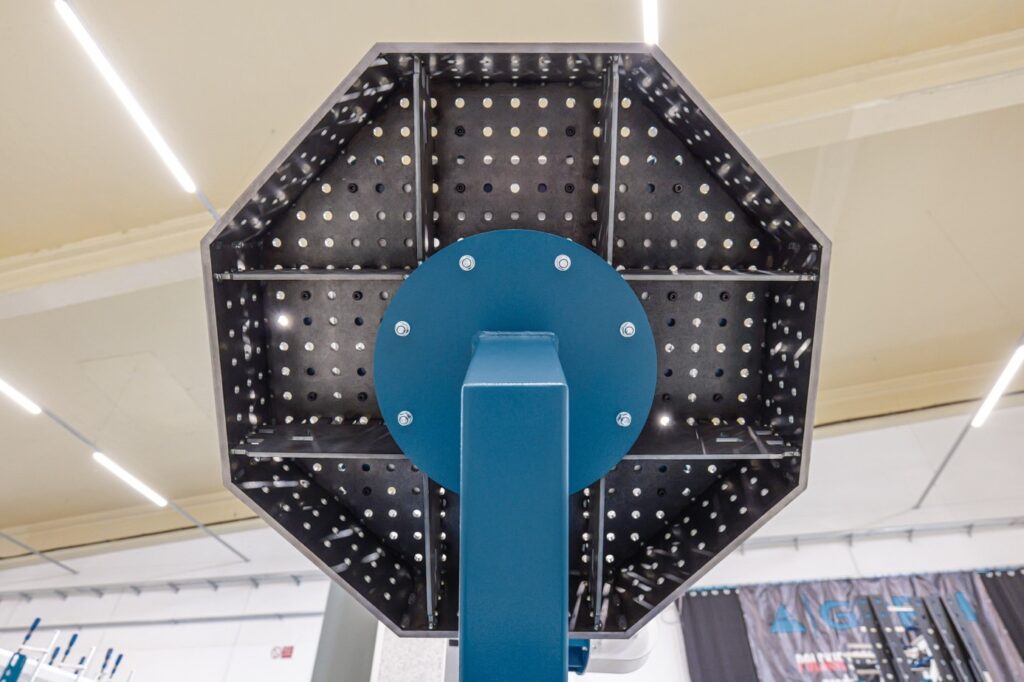

OCT octagonal tables are mainly used in manufacturing, especially where there is a need for automation and precision in welding processes. Their unique octagonal shape works perfectly with robotic welding systems, making them ideal for the automotive, aerospace and steel structure manufacturing industries.

Key features of the octagonal welding table series:

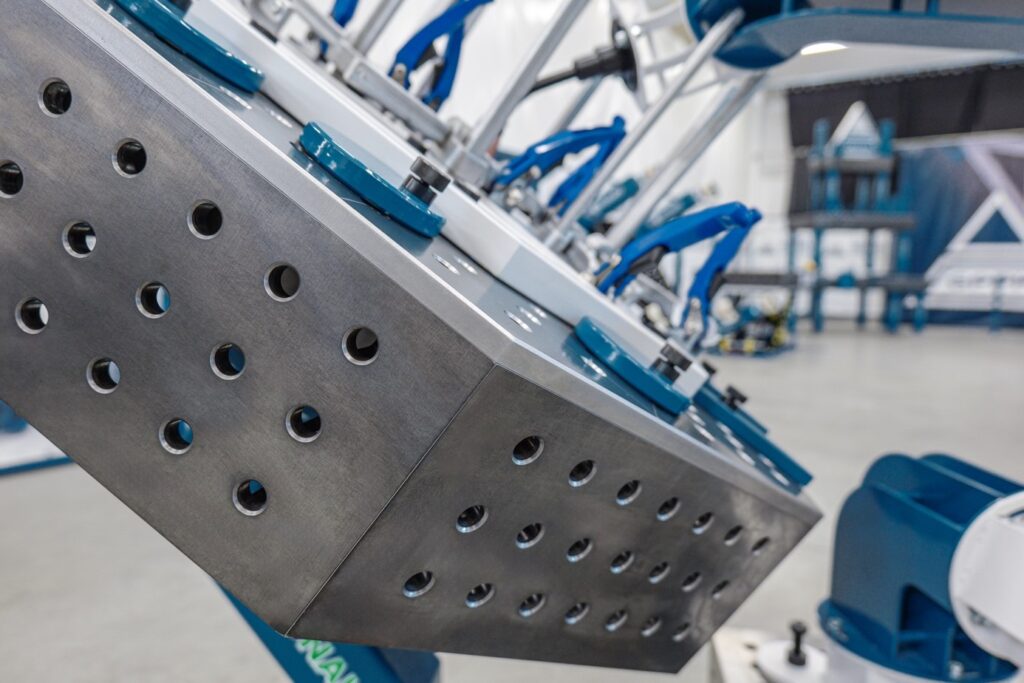

1. Precision at the highest level: The octagonal shape of the table allows precise positioning of components, which is extremely important in applications where every millimetre matters.

2. Flexibility for different applications: OCT octagonal tables are suitable for use with various welding robots, making them a versatile tool in production.

3. Stability and durability: the construction of the GPPH tables is based on high-quality materials, which guarantees the stability and durability of the tables even under conditions of intensive use.

4. Workspace optimisation: The octagonal shape allows for optimal use of the working space, which is extremely important for production facilities.

5. Workspace optimisation: The octagonal shape allows for optimal use of the working space, which is extremely important for production facilities.

The octagonal welding tables are available with PRO (15 mm) and PLUS (12 mm) tops, as well as in grids: fi 16 mm in diagonal, fi 16 mm in 50x50 mm and fi 28 mm in diagonal. In addition, they are available in stainless steel and in various dimensions: 600x600, 1000x1000, 1200x1200 and 1400x1400.

The OCT octagonal table series from GPPH is the answer to the industry's growing need for automation and precision in welding processes. Thanks to their innovative features and flexibility, they are an indispensable tool for professional manufacturers who strive for excellence in their production processes.