Welding tables in the workshop: how to optimise the workspace?

Effective workplace organisation is crucial in welding workshops to maximise productivity and ensure safety. Welding tables play a key role in creating a functional and organised environment. In this article, we will look at how the right welding workshop layout and the proper use of welding tables can improve productivity and safety. We will touch on strategies that make the best use of the available space, and present examples of welding tables that can be adapted to suit the needs of both small and large workshops.

Workspace optimisation with welding tables

- Table selection: Choose welding tables that suit the size of your workshop and the welding tasks you perform. You can choose either traditional welding tables with legs on feet or wheels, tables with a hydraulic lifting system or, for example, rotary tables that are ideal for robotic welding. Welding tables with legs on wheels offer flexibility in handling heavy components.

- Alignment planning: Design the layout of the workshop to optimise workflow. Welding tables can be strategically placed to facilitate material handling, welding organisation and post-welding activities such as quality control and finishing.

- Maintain order: All tools and materials should have a fixed place. Using shelves under welding tables or tool trolleys allows you to quickly find the things you need.

Improving workplace efficiency

- Division of work zones: It is useful to divide the workshop into zones, such as the welding, assembly or cleaning zone. Each should be equipped with the right tools and equipment to minimise set-up time and streamline operations.

- Ergonomic issues: Adjust the height of the table to ensure an ergonomic welding position to minimise fatigue and improve welding quality.

- Ventilation and safety: Provide adequate ventilation and a clear layout of the work area to minimise exposure to dust, welding fumes and other hazards. Place welding tables away from high traffic areas to provide clear paths for safe movement.

Examples of welding tables

- Traditional stationary tables: Ideal for small as well as large workshops or specific welding workplaces. These tables provide a stable surface for welding and assembly tasks.

- Tables with hydraulic lifting system: Modern technology that guarantees optimum comfort and productivity. Thanks to the automatic height adjustment function of the table top, you have the possibility to quickly and accurately adjust it to your personal requirements, enabling you to achieve the perfect working height.

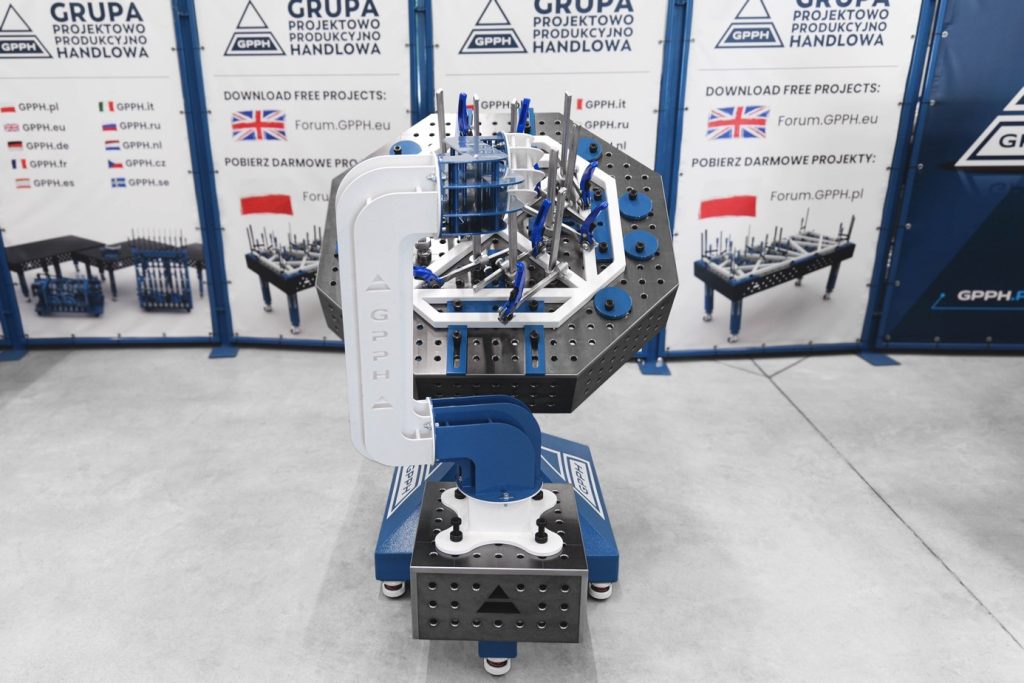

- Rotary tables: Specialised tables that facilitate welding at complex angles and positions. These tables are valuable for precision welding and assembly of complex components. Designed with robotisation in mind, rotary welding tables are an innovative solution for industries that focus on automating their welding processes.

Efficient use of welding tables is essential to optimise productivity in welding workshops. By carefully selecting tables that match the size of the workshop and the welding tasks being performed, welders can create an environment conducive to high-quality welding operations. Whether it is a small garage workshop or a large industrial facility, welding tables contribute significantly to work efficiency, operator comfort and overall workshop productivity.